Closed punch overload protection device

An overload protection and overload technology, which is applied in the field of stamping equipment, can solve problems such as machine damage and stamping material scrapping, and achieve the effects of improved safety, low maintenance cost, and high scrapping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

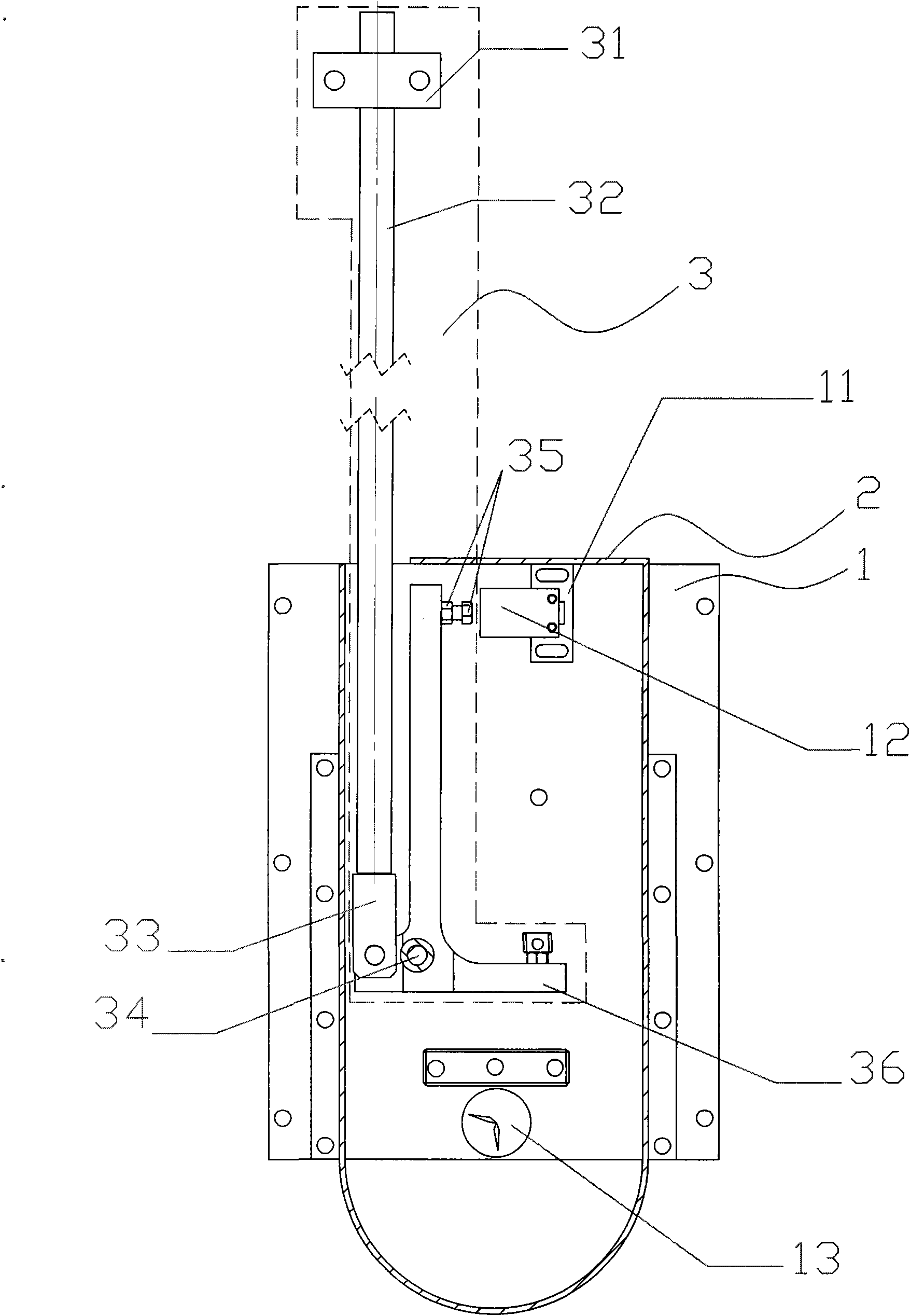

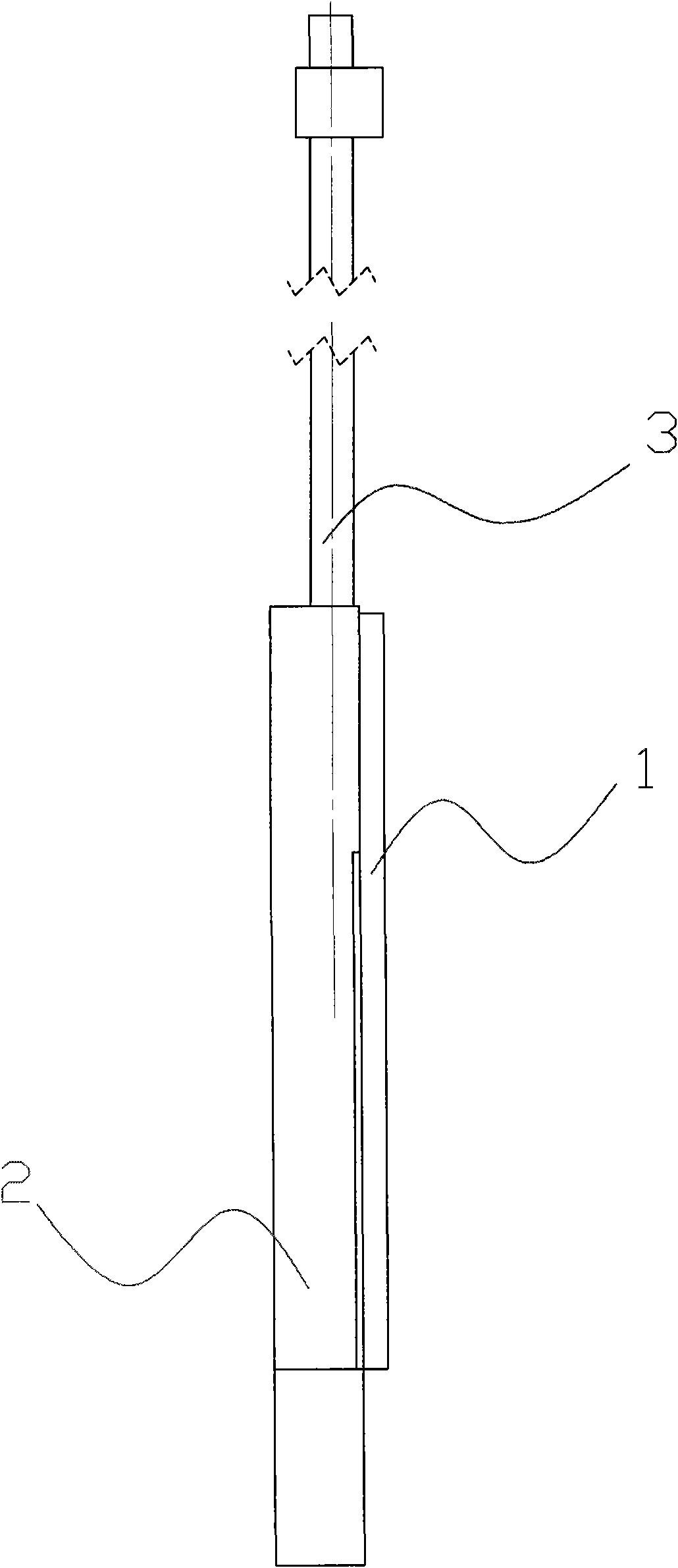

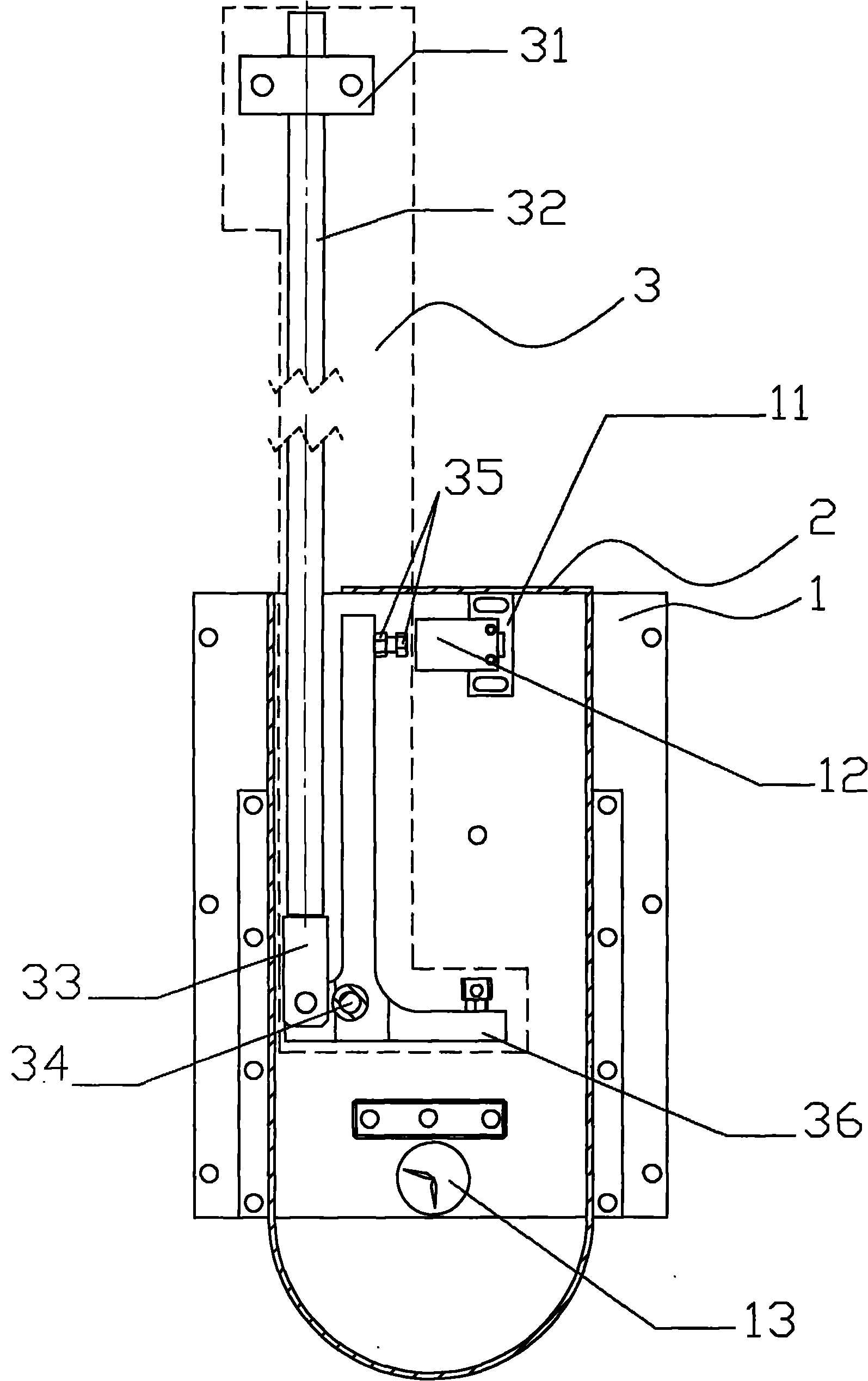

[0014] refer to figure 1 , figure 2 , a closed punch press overload protection device, including a first fixed seat 1 fixed on the frame and an overload detection mechanism 3, one end of the overload detection mechanism 3 is pivotally arranged on the first fixed seat 1, and the other end Fixed on the frame of the closed punch press.

[0015] Such as figure 1 and figure 2 As shown, as a preferred embodiment of the present invention, the overload detection mechanism 3 includes a connecting shaft 32 and an inverted T-shaped connecting rod 36, one end of the connecting shaft 32 is fixed on the second fixing seat 31, and the other end is fixed There is a connecting rod seat 33, the middle part of the T-shaped connecting rod 36 is pivotally arranged on the first fixed seat 1 through a pivot 34, and one end of the T-shaped connecting rod 36 cross bar is hinged with the connecting rod seat 33, and the T-shaped connecting rod 36 The end of the vertical bar is provided with a prox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com