Hydraulic jacking automatic welding inverted construction method of large-sized storage tank

A large-scale storage tank and construction method technology, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of high investment of large cranes in high-altitude operations, and achieve the effects of reducing construction costs, improving work efficiency, and simple operation

Active Publication Date: 2010-11-24

陕西化建工程有限责任公司

View PDF0 Cites 38 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The welding quality of the tank can meet the requirements of the specification, and overcome the shortcomings of the "formal installation method" of large storage tanks, such as many high-altitude operations and large crane investment.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Login to View More

Abstract

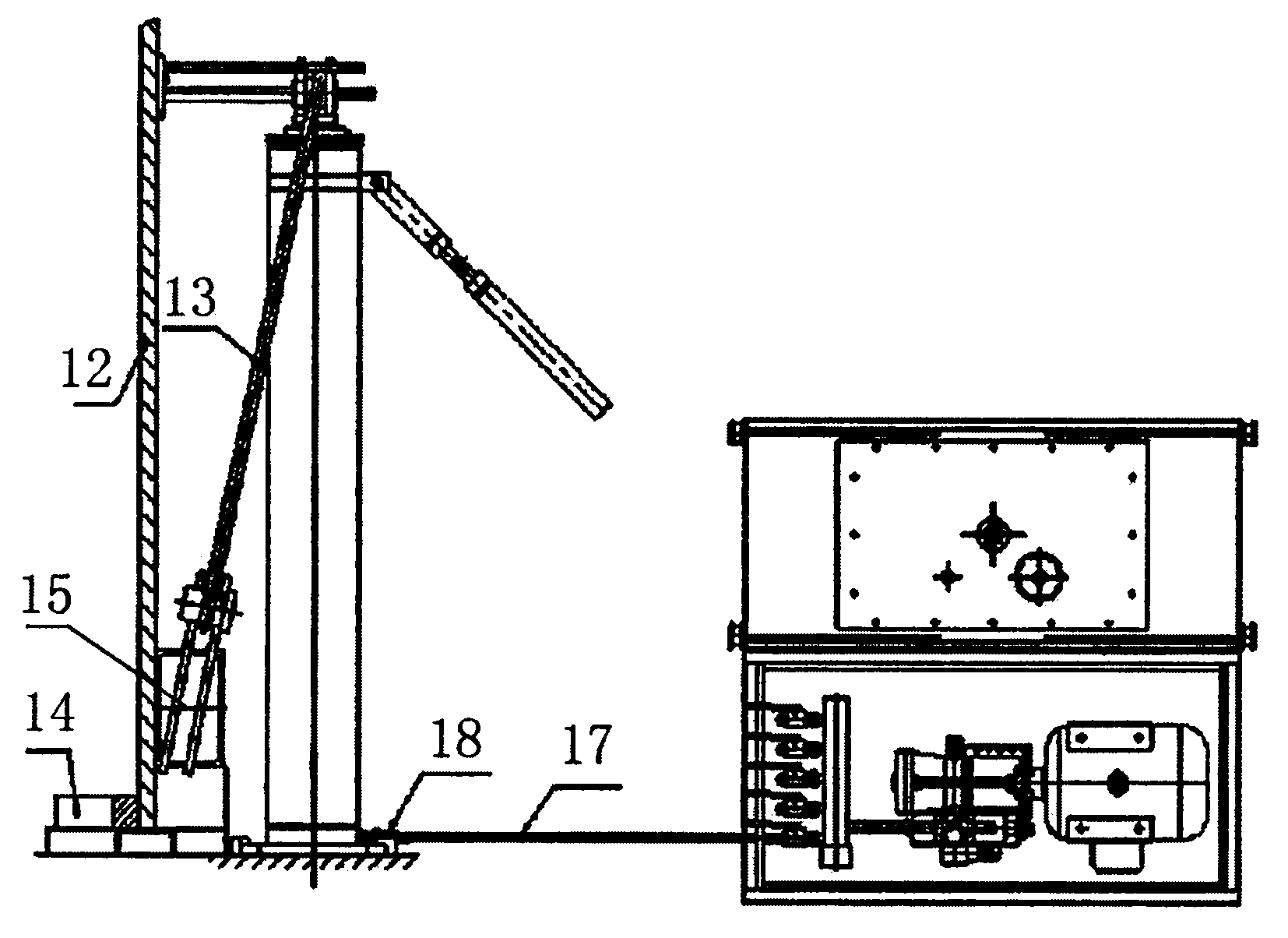

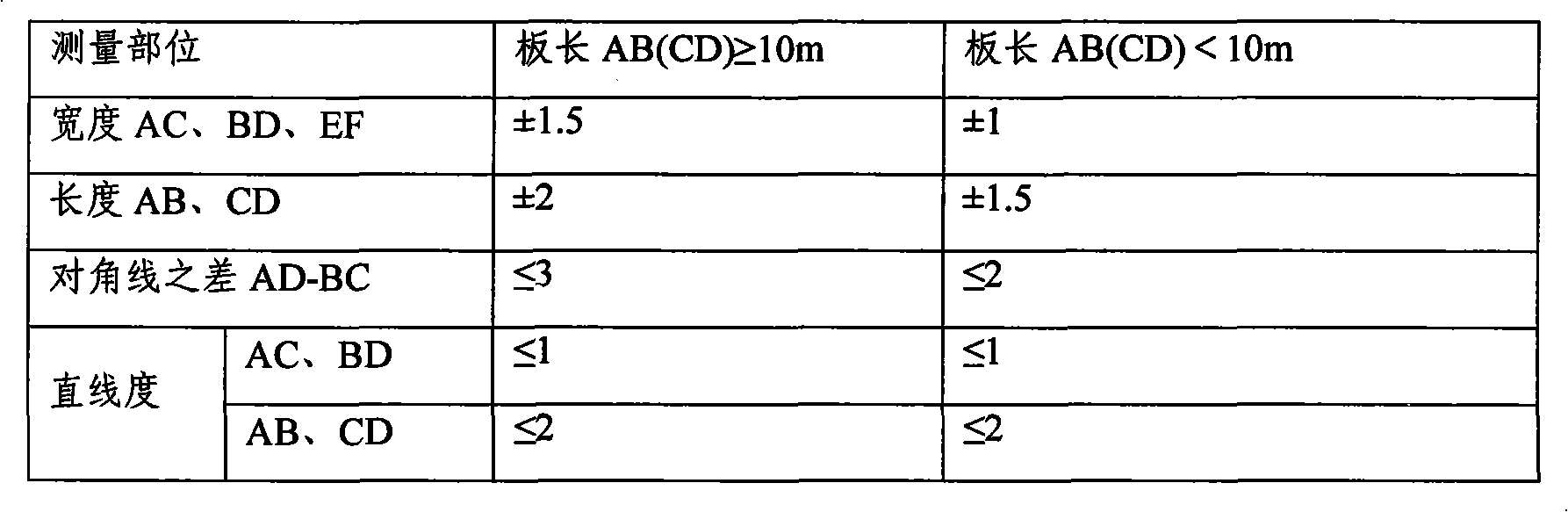

The invention relates to a hydraulic jacking automatic welding inverted construction method of a large-sized storage tank, which is safe, reliable and advanced. The welding quality of a tank body can satisfy standard requirements and overcomes the defects of more work high above the ground of a forward-erection method of the large-sized storage tank, large input quantity of a large-sized crane, and the like. The method comprises the following steps of: prefabricating a bottom plate, a wall plate, a floating roof and accessories; installing and welding a tank bottom plate; installing a hydraulic jacking device; installing tracks of a horizontal welding machine; welding butt seams and longitudinal seams of a top wall plate group; installing a tank top; lifting the wall plate; welding the wall plate, a surrounding plate and longitudinal seams; welding ring seams; installing a top wall plate; and welding an edge plate. The invention mainly reforms a 'submerged-arc longitudinal welding machine' of the 'forward-calculation method' from a 'hanging type' into a 'track type' in order to adapt to a 'reversed method'. The invention adopts a one-side welding double-side forming technology and adopts the 'reversed method' to overcome the disadvantages of a 'forward-erection method installing process of the large-sized storage tank.

Description

Construction method of hydraulic jacking, automatic welding and flip-chip for large storage tanks Technical field: The invention relates to a construction method, in particular to a hydraulic jacking and automatic welding and flip-chip construction method for a large storage tank. Background technique: With the rapid development of my country's economy and the continuous improvement of people's living standards, energy consumption has increased sharply, and the demand for petroleum and refined oil has increased sharply. At present, my country has become a major oil importer, and oil has become an important strategic material for the country. It is directly related to my country's economic development, social stability and national security. It is imminent to increase crude oil reserves. Therefore, my country's national oil reserves and refined oil depots Construction has been given great attention. Large vertical steel storage tanks are very important storage and transpor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K31/02B23K101/12

Inventor 王智杰何丹杨峰斌李丽红贺小锋南亚群

Owner 陕西化建工程有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com