Automatic distributor capable of delivering four screws for once

An automatic distributor and screw technology, applied in the field of supply, conveying device, automatic distributor, and automatic screw distribution, can solve the problems of difficult to achieve accurate screw delivery, difficult to achieve automatic screw distribution, strict consistency requirements, etc. Small, low environmental impact, the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

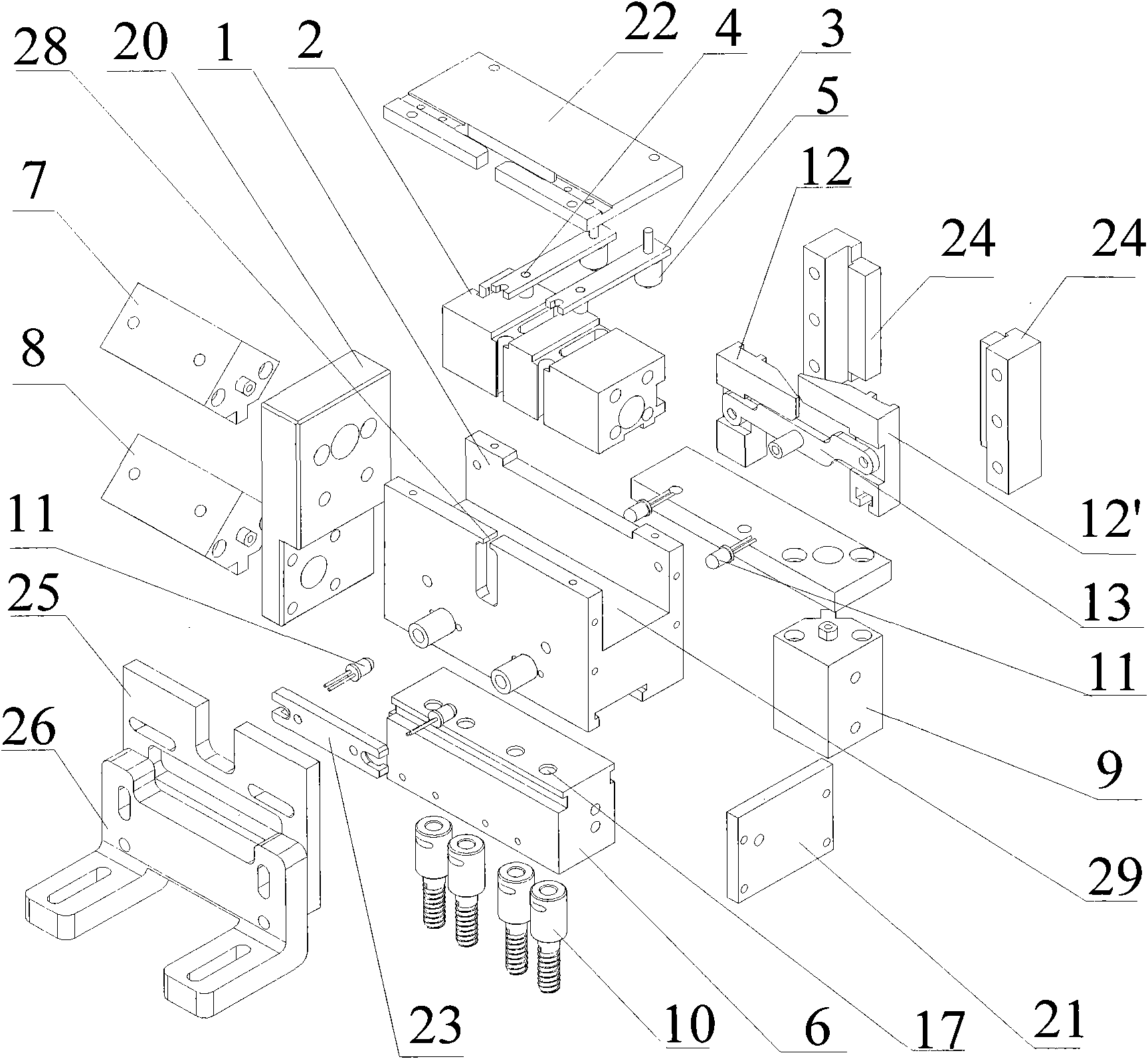

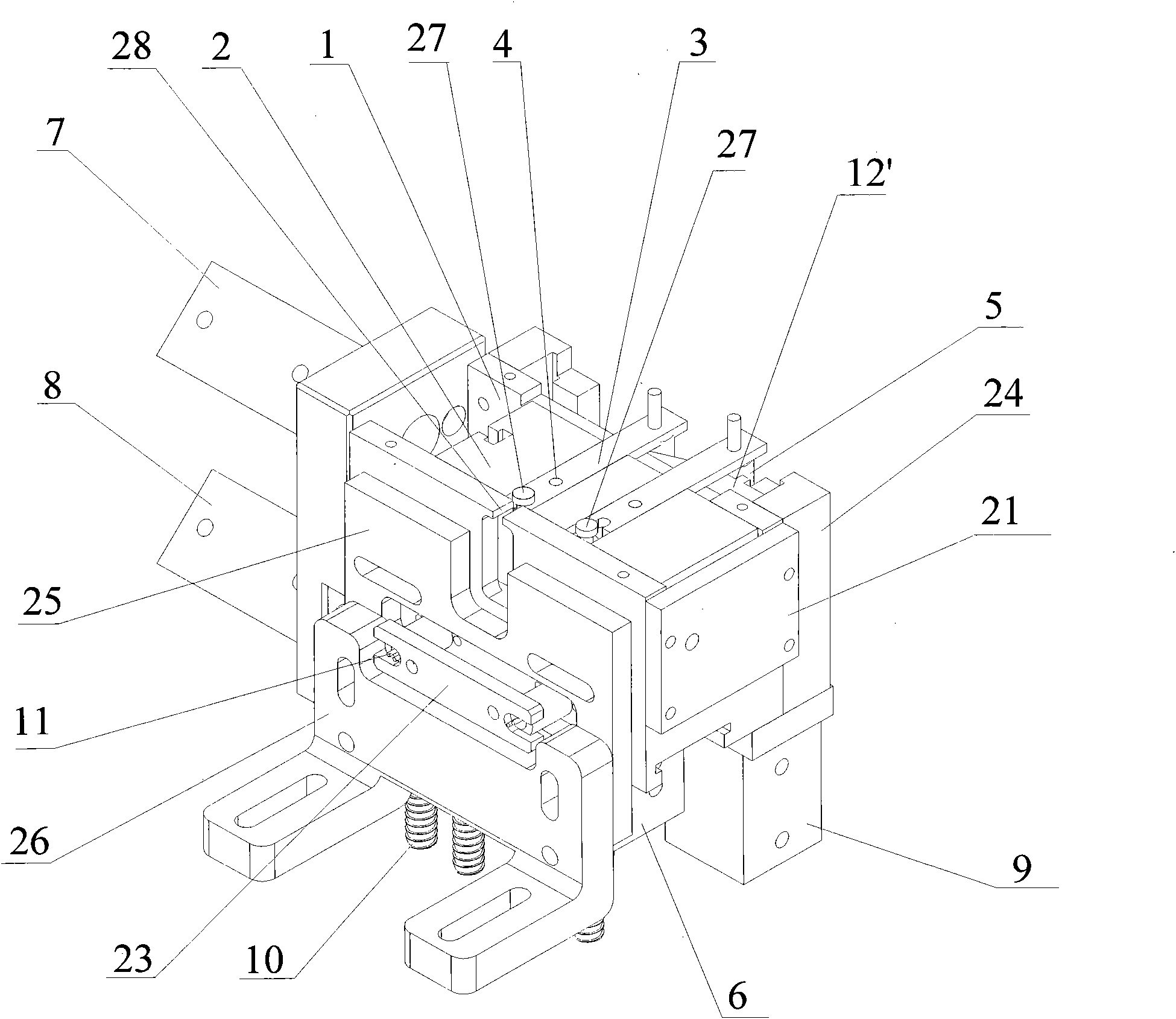

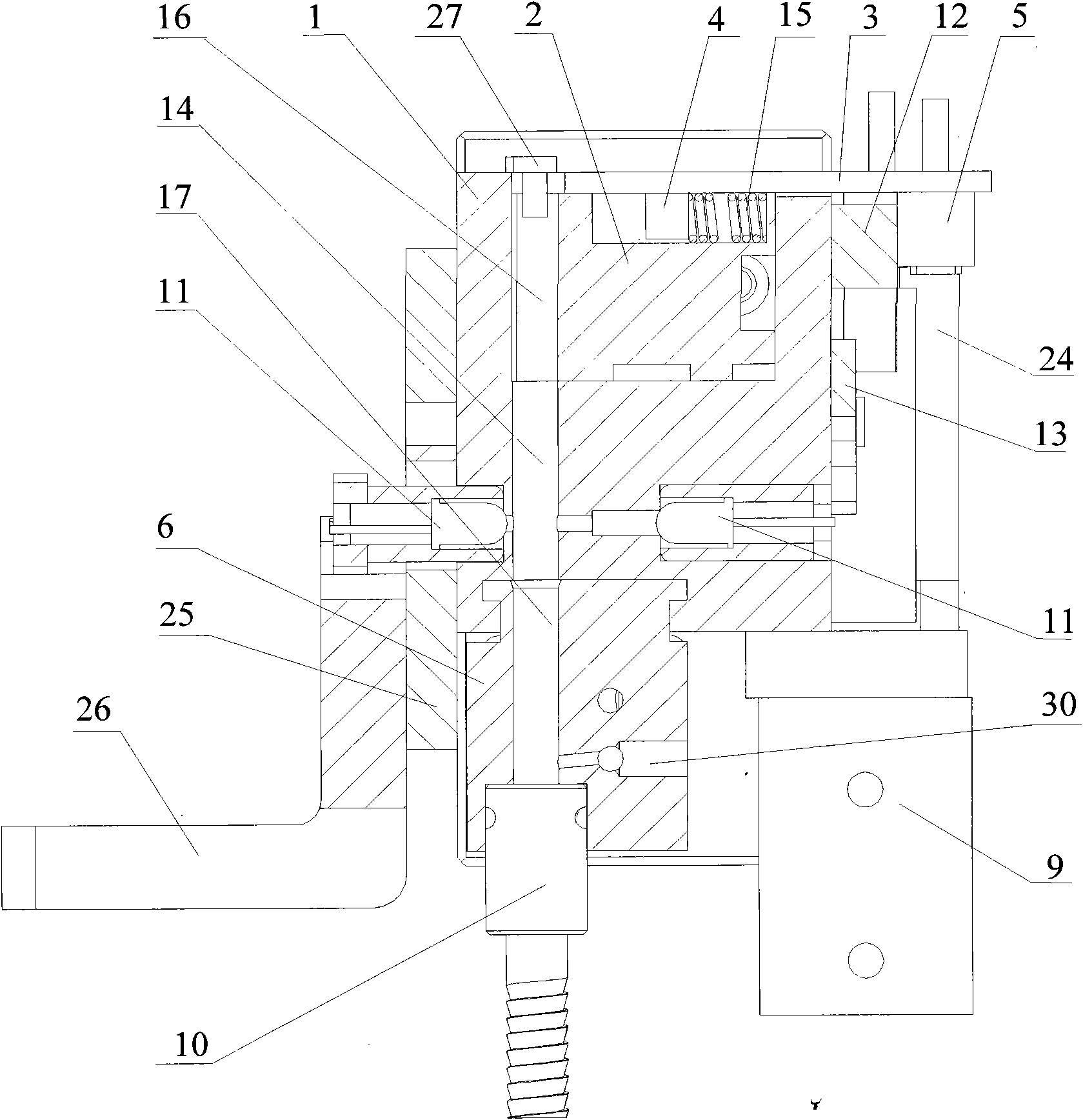

[0021] An automatic dispenser that outputs four screws at a time, such as figure 1 , figure 2 and image 3 As shown, an automatic program controller including an "L"-shaped connection block 26, an adjusting plate 25 and a distributor for installing and fixing the main body 1 connected to the automatic screw feeder, the main body 1 is provided with a screw delivery port 28 and a chute 29, The chute 29 provided on the body 1 is equipped with the two-point slider 2 connected with the two-point cylinder 7, and the "T" groove provided under the body 1 is equipped with a four-point slider 6 connected with the four-point cylinder 8, The right driving ramp 12' connected to the driving ramp cylinder 9 is installed under the main body 1 through the connecting plate, and the right driving ramp 12' is connected to the left driving ramp 12 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com