Quick disassembly and assembly device for heavy-duty vehicle track

A technology of an installer and a crawler, which is applied in the field of disassembly and installation of crawler maintenance, and can solve problems such as quick disassembly of the crawler end coupling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

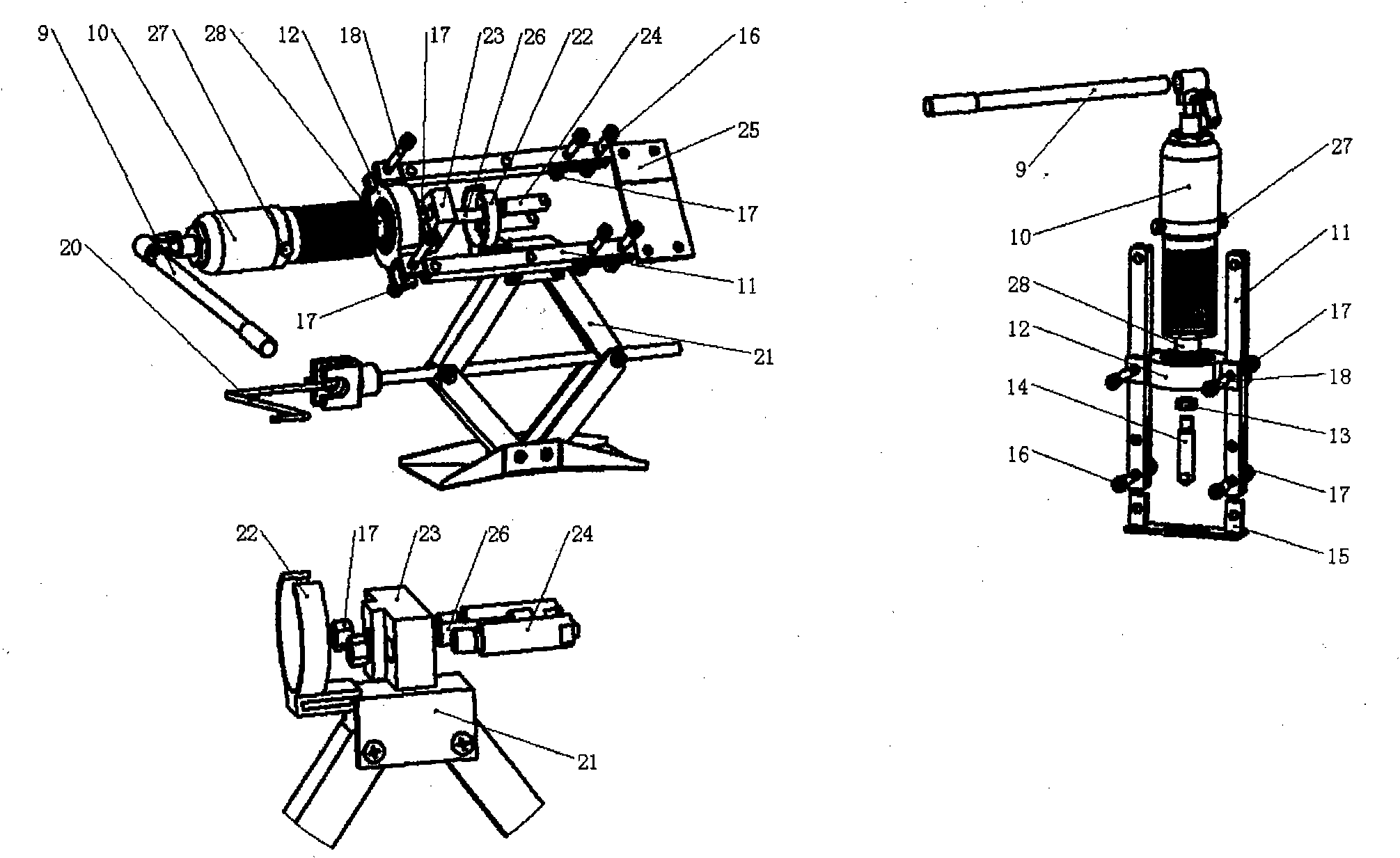

Embodiment Construction

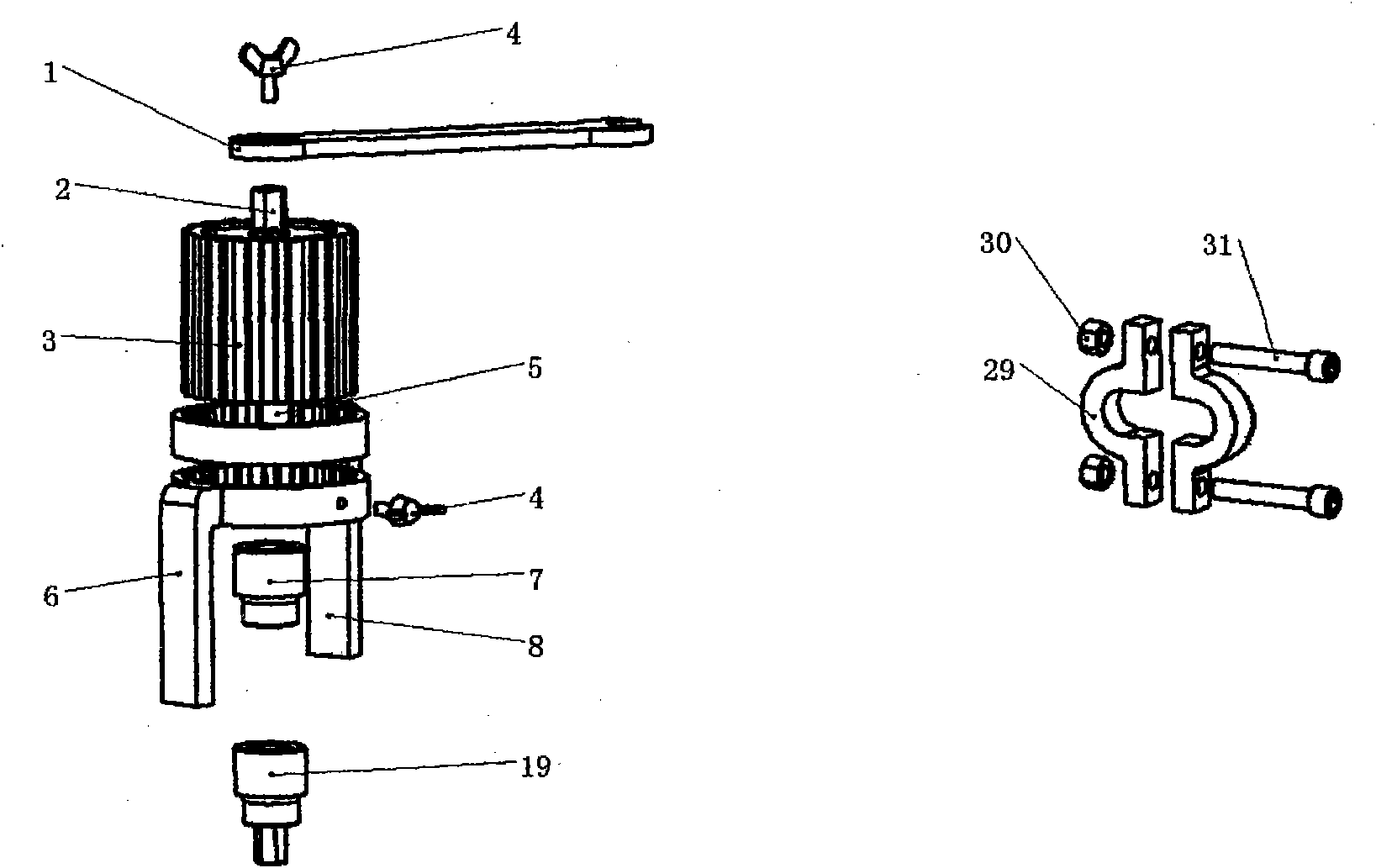

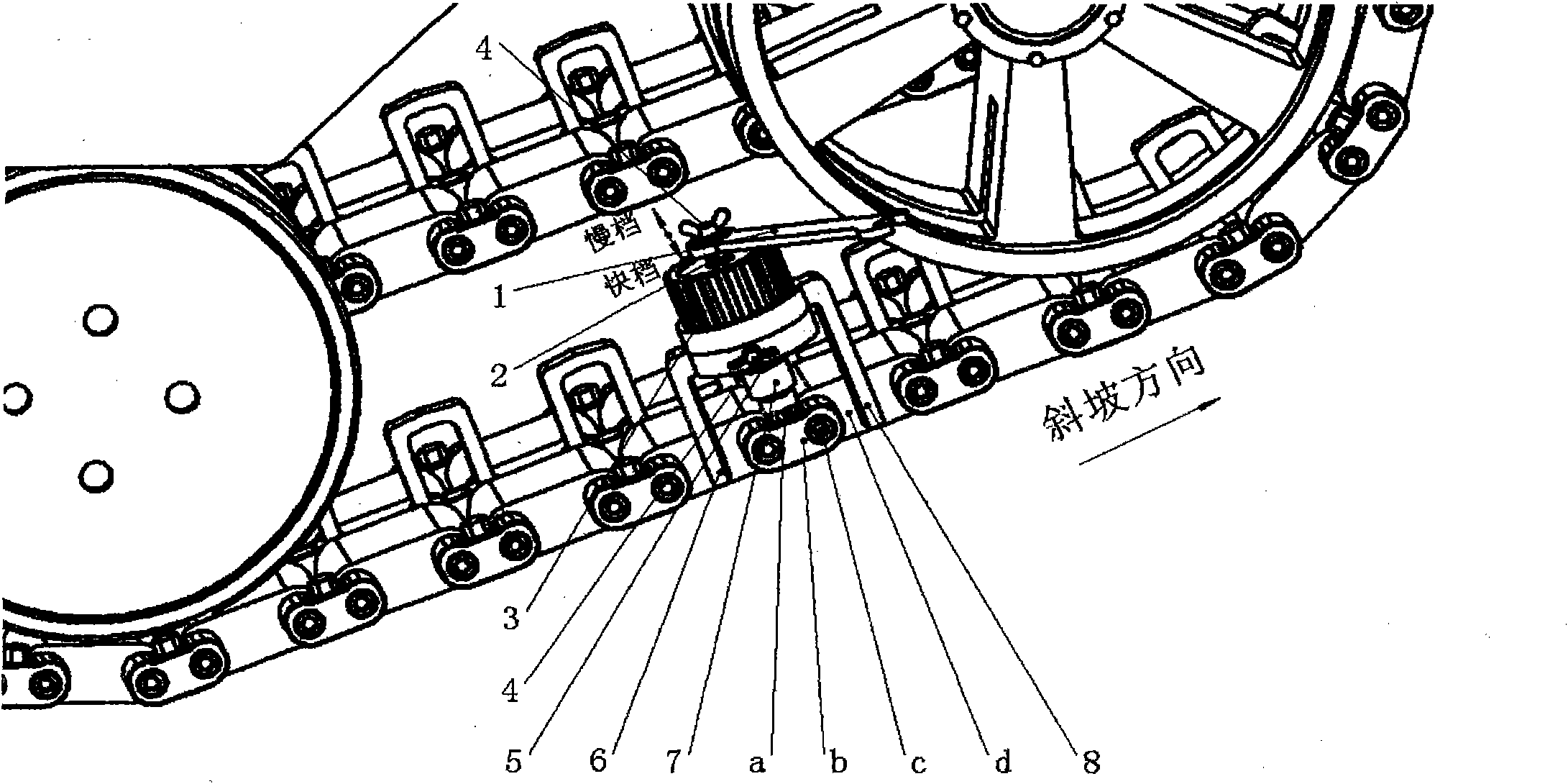

[0029] exist figure 2 , put the output shaft square head (5) of the multiplier wrench (3) with the sleeve (7) corresponding to the screw of the track end coupling, and the inner hexagon of the sleeve covers the screw (a) to be removed; the short stopper ( 6), the long retaining foot (8) takes the edge of the track shoe (d) as the support point; when operating, first use the ratchet wrench (1) to cover the hexagonal point of the small input shaft (2), and then use the butterfly screw (4) to lock it Ratchet wrench (1) prevents it from coming out of the hexagon of the small input shaft. When loosening the screw (a) (pay attention to the direction of rotation of the screw), first use the slow gear (the small input shaft is pulled out to be the slow gear, and the force ratio at this time is 1:56 ;) Loosen the screw, and then use the fast gear (the small input shaft is pushed forward to be fast, and the force ratio is 1:3.8 at this time), and the screw can be quickly removed. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com