Workpiece turning and hanging universal process of large revolving body and tooling attachment thereof

A process method and a technology for a body workpiece, which are applied in the field of a general process method for flipping and hoisting large-scale rotary body workpieces and their tooling attachments, and can solve problems such as mutual reuse and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

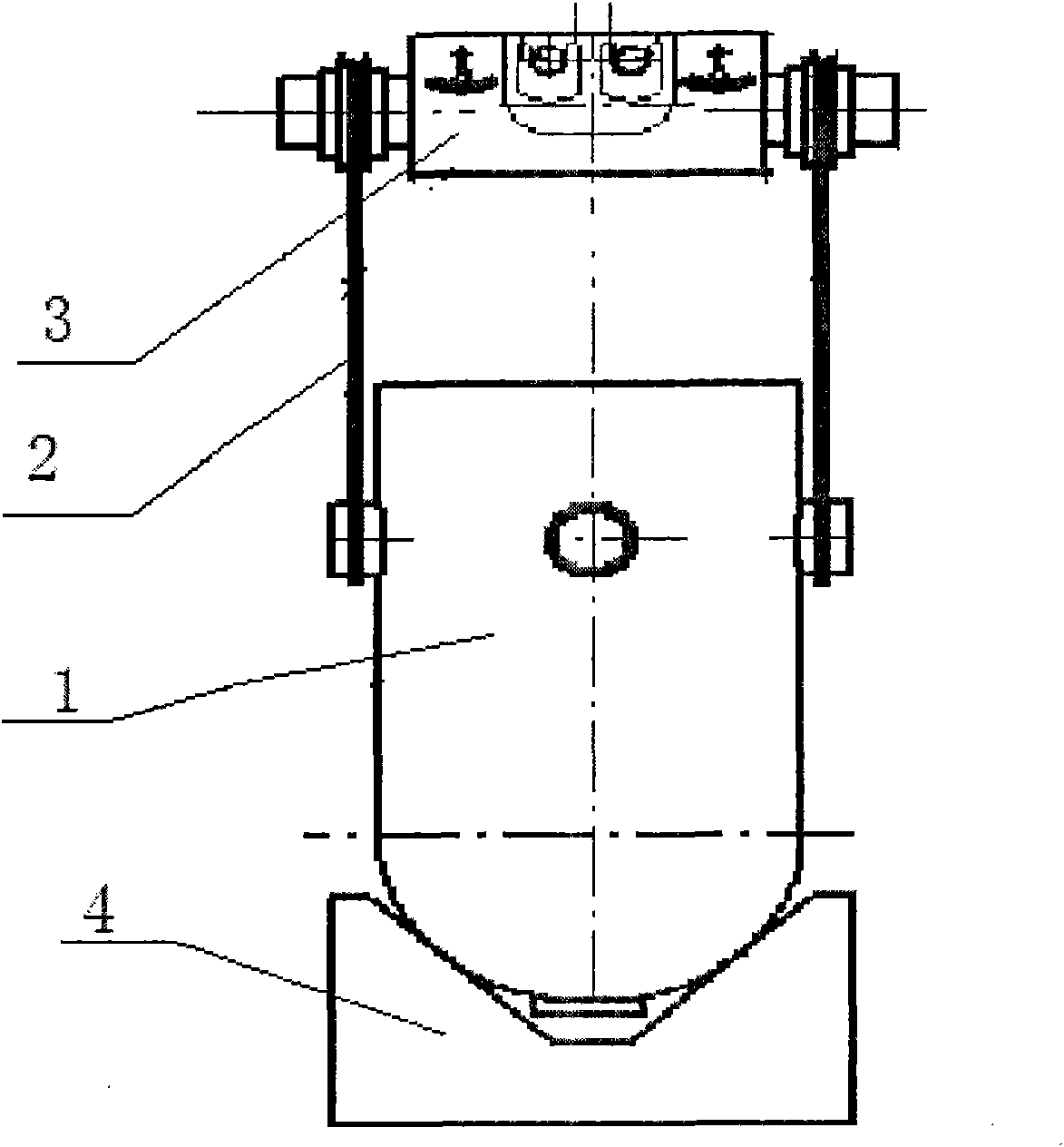

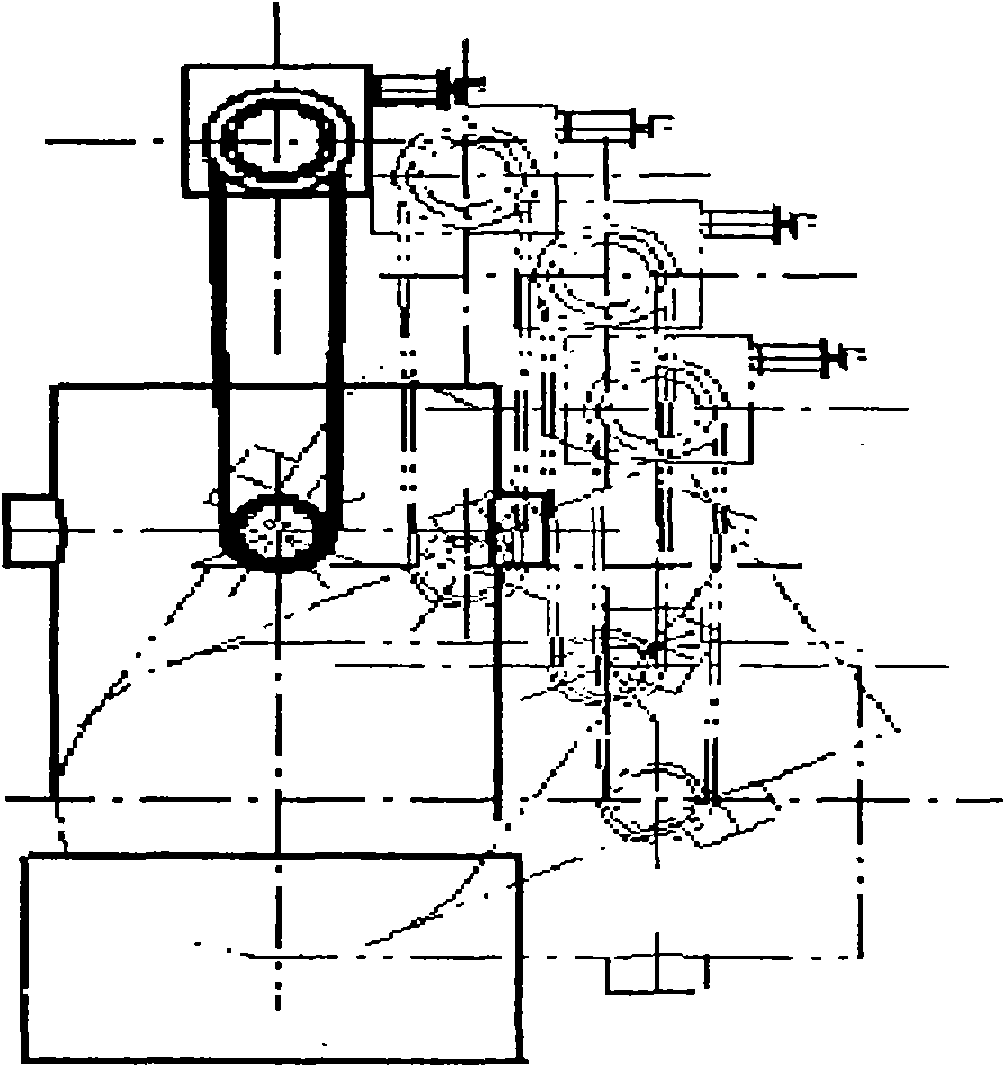

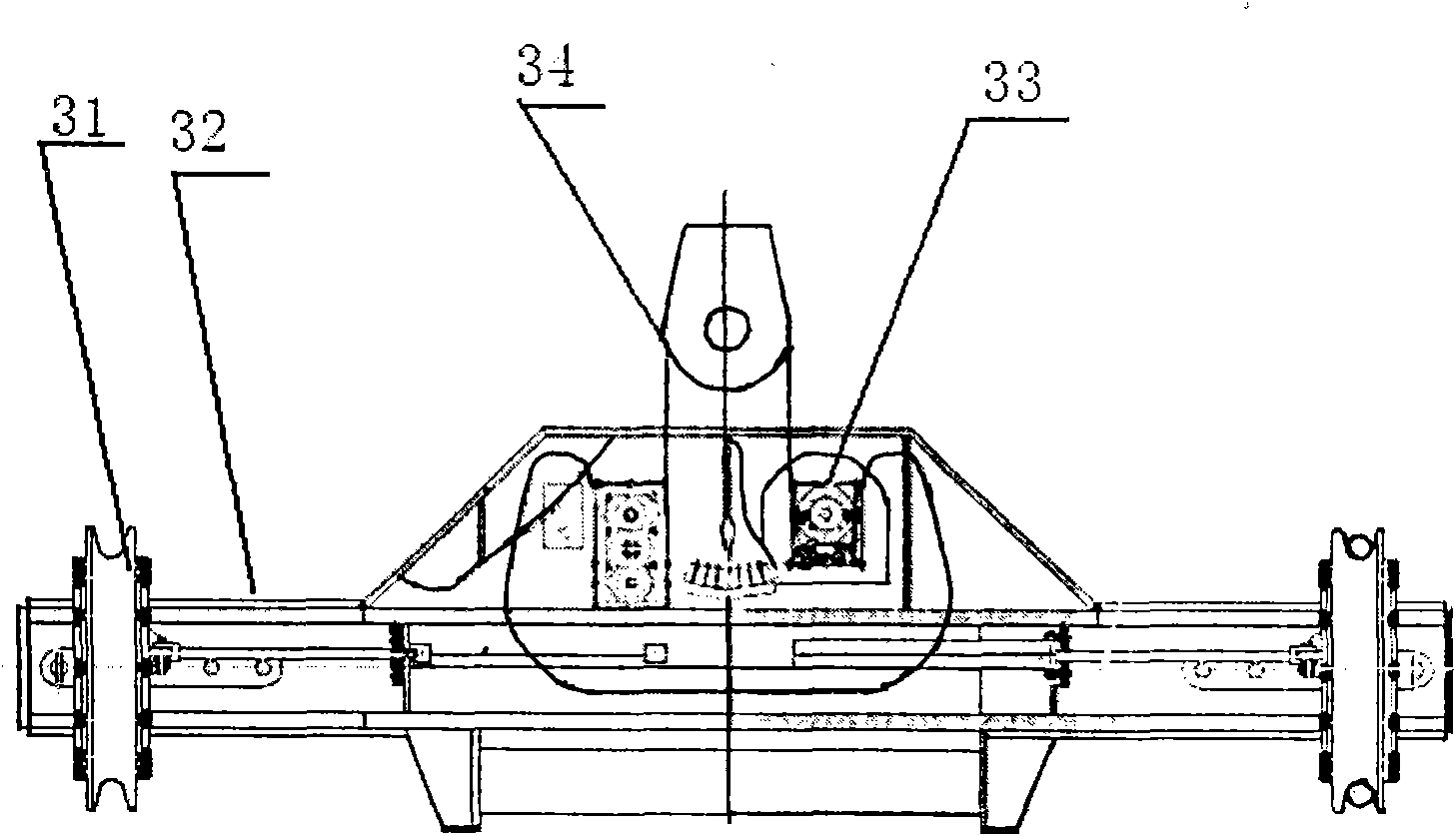

[0022] Such as figure 1 with figure 2 As shown, the general process method for turning and lifting large-scale rotary workpieces includes two technological methods of turning the workpiece 1 from horizontal to vertical and from vertical to horizontal. Usually, the workpiece 1 is in the In the horizontal state, the workpiece 1 is first turned from horizontal to vertical, and then the workpiece enters the next processing program. After completion, the workpiece 1 is turned from vertical to horizontal, and the workpiece 1 is turned from horizontal to vertical. It is: in the designated flipping site, first move the object to be lifted to a platform without rigid pads, place the workpiece 1 along the flipping direction, and place the non-rigid pads on the lower end of the workpiece (the lower end is vertical) , according to the hanging point position size of the upper end of the suspended object (upper after being vertical), utilize the remote control function of the spreader to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com