Sputtering turntable and sputtering device used by same

A sputtering and turntable technology, applied in the field of turntable devices, can solve problems such as uneven distribution of ions, affecting the sputtering effect of the sputtering device 10, and achieve the effect of improving the sputtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

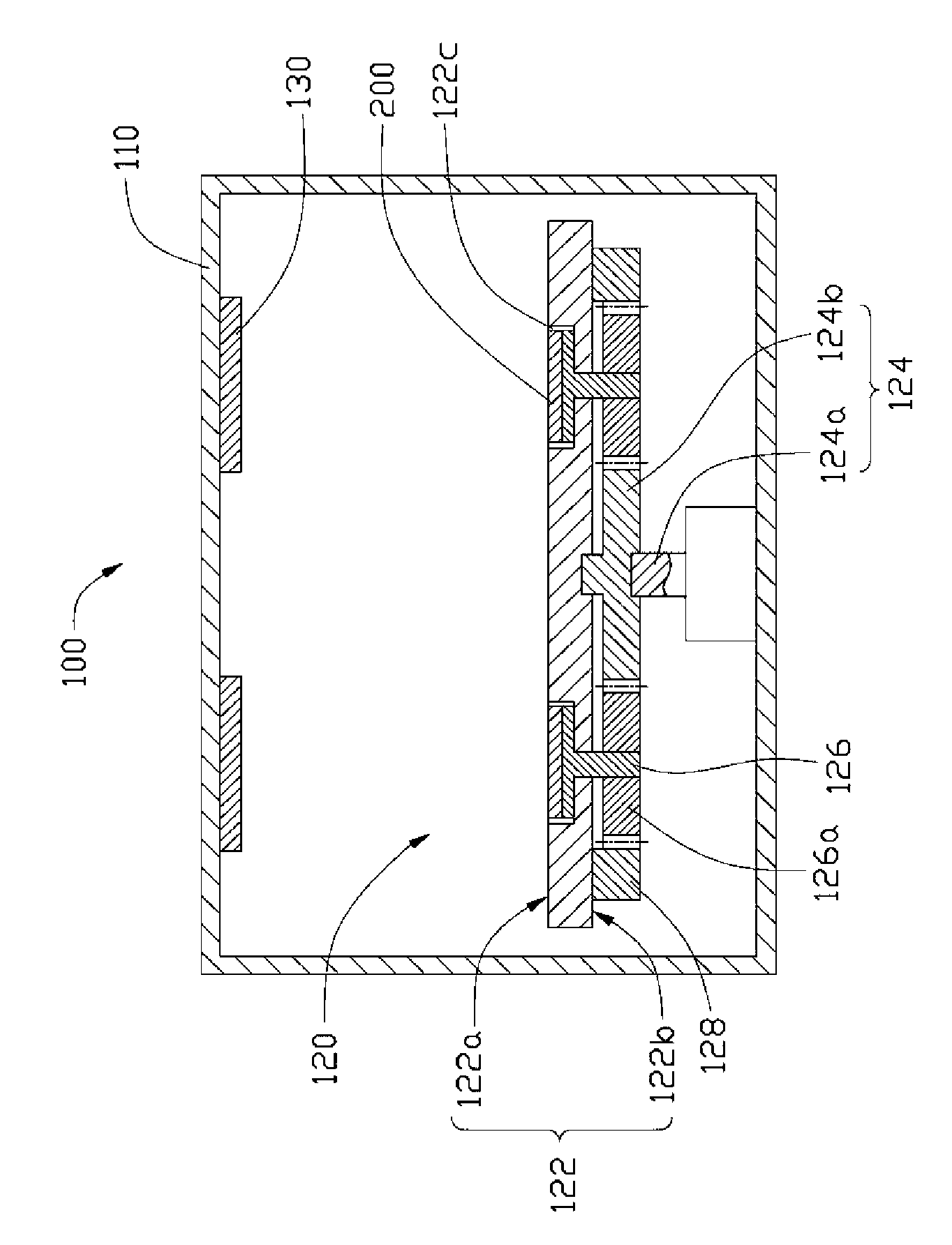

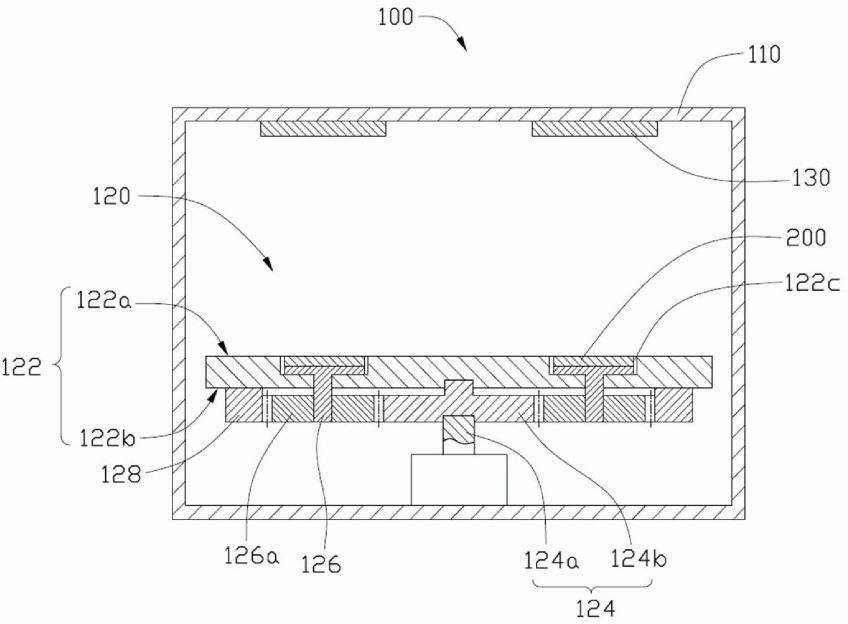

[0009] see figure 2 , a sputtering device 100 provided in a preferred embodiment of the present invention. The sputtering device 100 includes an accommodating cavity 110 , a sputtering turntable 120 , and at least one target 130 . The sputtering turntable 120 is disposed at the inner bottom of the accommodating cavity 110 . The target 130 is disposed on the inside of the top of the accommodating cavity 110 at a certain distance from the sputtering turntable 120 .

[0010] The accommodating cavity 110 is used to form a space for sputtering. The accommodating cavity 110 can be evacuated by a vacuum machine and filled with a suitable gas such as argon. A glow discharge device (not shown in the figure) is also provided in the accommodating cavity 110 to ionize the argon gas filled in the accommodating cavity 110 to generate plasma that can strike the target 130 . In addition, a strong magnetic field can be provided in the accommodating cavity 110 to accelerate the plasma, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com