Rollover toilet with annular trap

A water trap and flip-type technology, which is applied in the field of sanitary ware products, can solve the problems of large water trap resistance, large space occupied by the toilet, and easy generation of air pockets, etc., so as to achieve fast and smooth water flow and improve the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

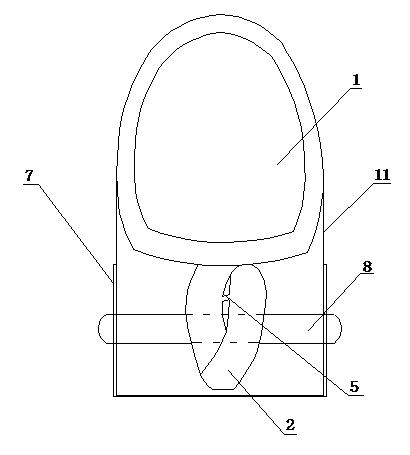

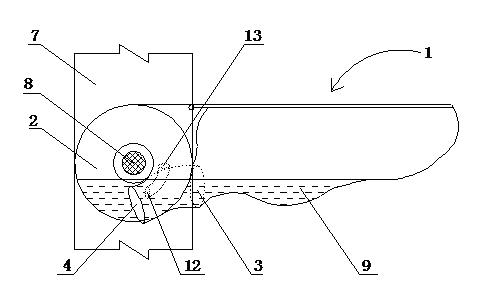

[0033] Embodiment 1: A flip-up toilet with an annular trap, including a toilet body 1, a bracket 7 and a trap 2, the bracket 7 is fixed on the ground, the trap inlet 3 and the sewage outlet at the bottom of the toilet body 1 Connect, trap outlet 4 is connected with sewer through hose, toilet main body 1 is installed on the rotating shaft 8 by a toilet arm 11, rotating shaft 8 is fixed on the support 7, makes toilet main body 1 turn around rotating shaft 8. The water trap 2 is a ring-shaped structure made of hollow pipes. The water trap 2 surrounds the rotating shaft 8 and rotates around the rotating shaft 8 with the toilet main body 1 . The cross-sectional shape of the trap 2 pipe is circular, the diameter of the nozzle from the trap inlet 3 to the trap outlet 4 gradually decreases, and the diameter of the round pipe at the trap outlet 4 is smaller than that at the trap inlet 3 The diameter is 10% smaller, so that the pressure on the liquid flowing through the trap 2 is contin...

Embodiment 2

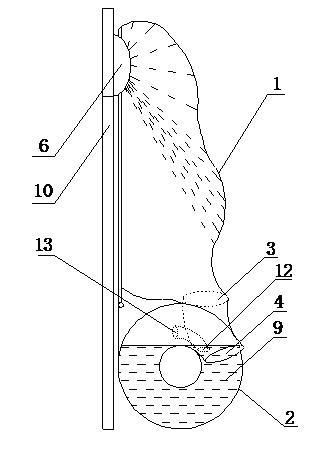

[0036] Embodiment 2: A flip-up toilet with an annular water trap, including a toilet body 1, a bracket 7 and a water trap 2, the bracket is fixed in the wall, the cross-sectional shape of the water trap 2 is oval, and the water trap The diameter of the elliptical tube at the exit 4 of the bend is 5% smaller than the diameter of the elliptical tube at the entrance 3 of the trap, and a section of the entrance 3 of the trap is offset to the right of the trap 2, and the rest are the same as in Example 1. When the toilet is closed, Half of the toilet main body 1 is embedded in the wall 10, reducing the space taken when the toilet is not in use.

Embodiment 3

[0037] Embodiment 3: A flip-up toilet with an annular water trap, including a toilet body 1, a bracket 7 and a water trap 2. The cross-sectional shape of the pipe of the water trap 2 is circular, and the ellipse at the outlet of the water trap 4 The diameter of the pipe is 7% smaller than the diameter of the elliptical pipe at the entrance of the trap 3, and all the others are the same as in Embodiment 1. When the toilet is closed, the toilet main body 1 is close to the wall 10 to reduce the occupied space when the toilet is not in use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com