Novel leak test valve

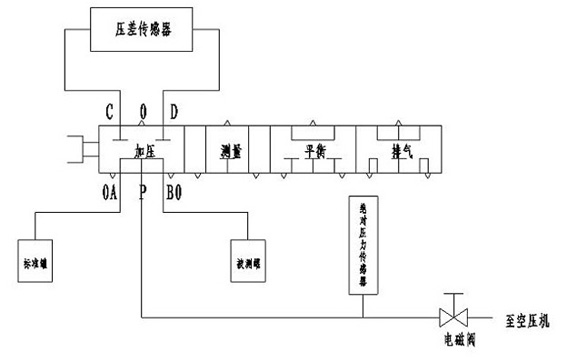

A new type of leakage detection technology, applied in valve details, multi-way valves, valve devices, etc., can solve the problems of complex structure, cumbersome operation, large error, etc., and achieve the effect of high connection efficiency, convenient operation, and small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

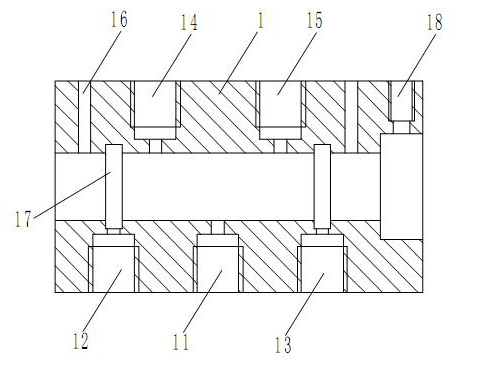

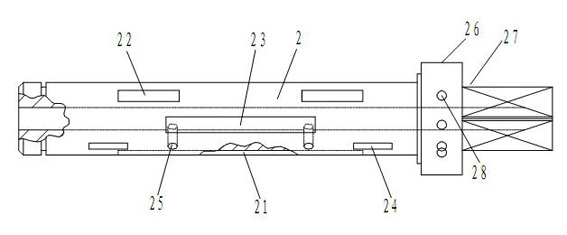

[0027] refer to Figure 1-3 , a novel leak detection valve, including a valve body 1 and a rotatable valve core 2, the valve core 2 is installed in the valve body 1, and the valve body 1 is provided with a threaded hole, an exhaust hole 16 and a positioning threaded hole 18, The first threaded hole 11 is connected to the air compressor, the second threaded hole 12 and the third threaded hole 13 are respectively connected to the standard container and the container to be tested, and the fourth threaded hole 14 and the fifth threaded hole 15 are respectively connected to two pressure sensors. At the end, the valve body 1 has an inner ring groove 17 at the second threaded hole 12 and the third threaded hole 13; position, the circumferential direction of the spool 2 is provided with grooves along the axial corresponding positions of each gear position, and the pressure groove 21 can pressurize the inside of the first threaded hole 11, the second threaded hole 12, and the third thr...

Embodiment 2

[0035] refer to Figure 8 The difference between this embodiment and the first embodiment is that the outer side of the valve core 2 is covered with a corresponding adapter to connect with the motor. In this embodiment, the motor drives the spool to rotate, and the rest of the structures and functions are the same.

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com