Bamboo charcoal warm paste

A bamboo charcoal and warm paste technology, applied in the directions of heating appliances for treatment, cooling appliances for treatment, heating fuel, etc., can solve the problems of excessive maximum heating temperature, short duration of heating, low temperature burns, etc. The effect of peak value, large market value, and stable heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

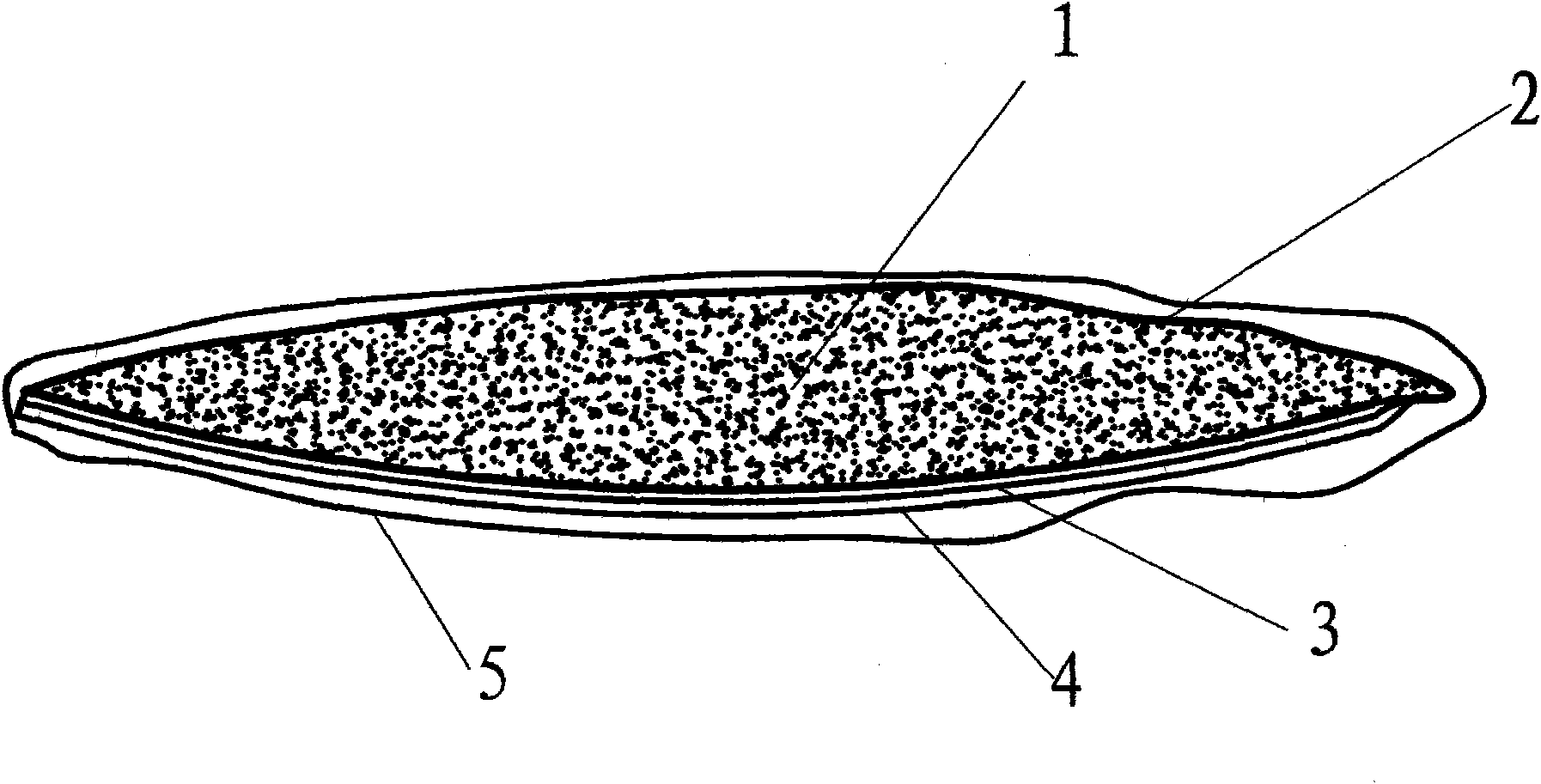

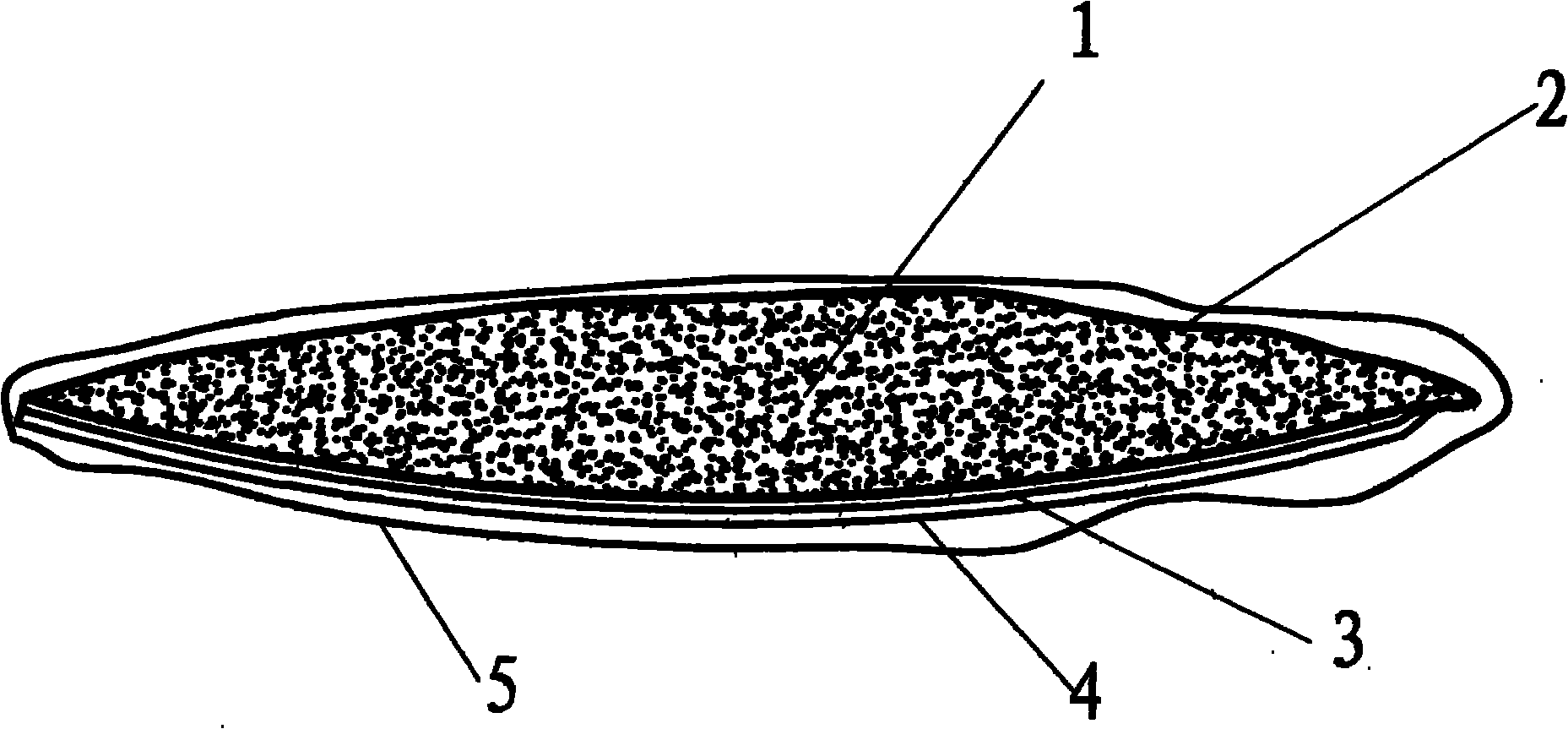

[0011] Referring to the accompanying drawings, the present invention includes a covering layer 4, an adhesive layer 3, a bag body 2, a heating material 1 and a sealed bag 5, and an adhesive layer 3 is arranged on the outer surface of the bag body 2; Peelable cover layer 4; heating material 1 is housed inside the bag body 2, and a sealed bag 5 is covered outside the bag body 2, and it is characterized in that: described heating material comprises bamboo charcoal, iron powder, sodium chloride, mica, Absorbent resin, vermiculite.

[0012] The weight of each component of the heating material 1 is: 250--350g of bamboo charcoal, 50--150g of iron powder, 50--150g of sodium chloride, 100--200g of water-absorbing resin, 50--150g of vermiculite; The particle size of each component in material 1 is 60 mesh - 100 mesh.

[0013] In the first embodiment of the present invention, the weight of each component of the heating material is: bamboo charcoal 250-300g, iron powder 50-100g, sodium c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap