Sampling packet for detecting salt density value of power external insulation equipment and sampling method thereof

A technology of external electrical insulation and salt density value, applied in the direction of sampling devices, etc., can solve the problems of inconvenient transportation of samples, heavy workload, easy freezing of scrubbing water, etc., and achieve the effect of convenient sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

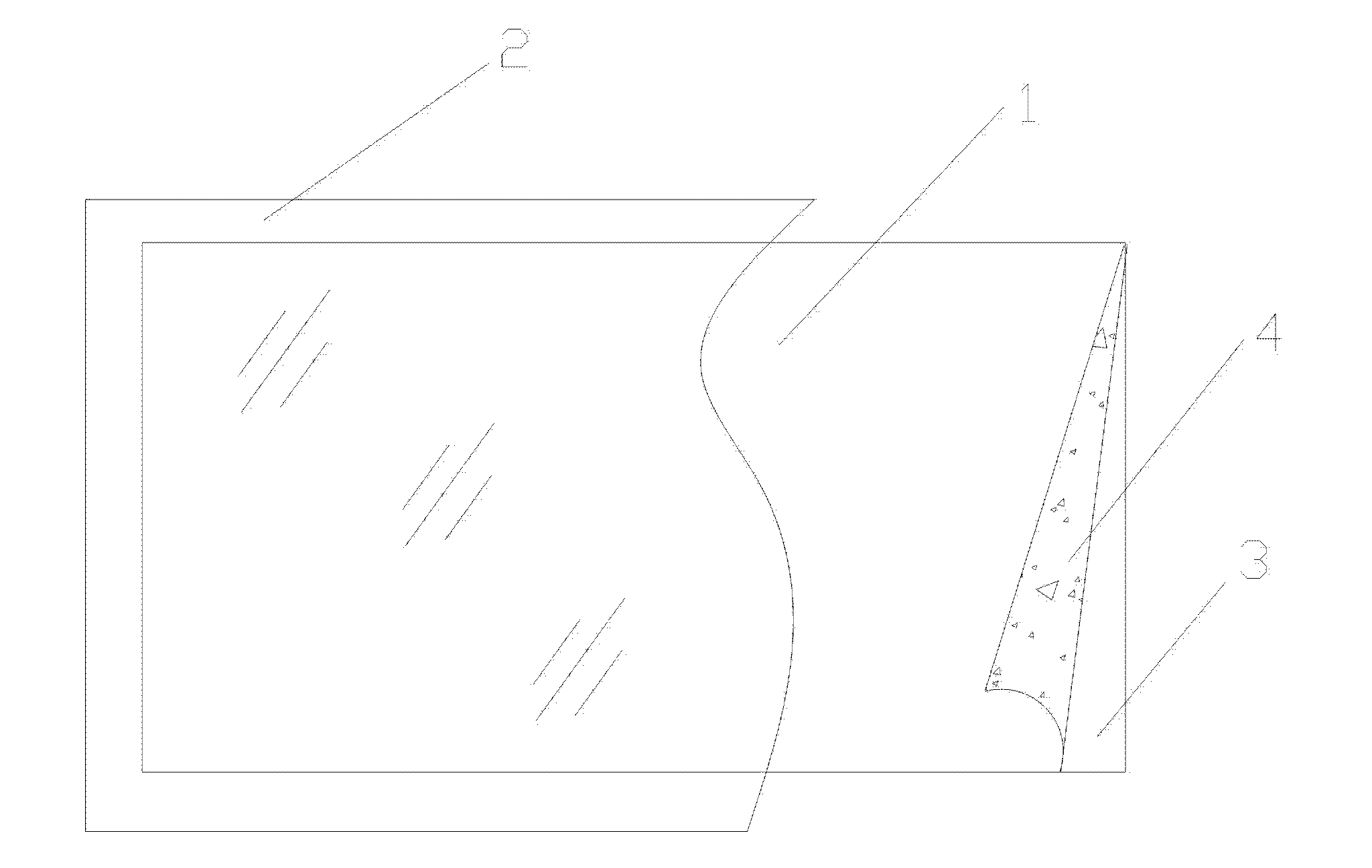

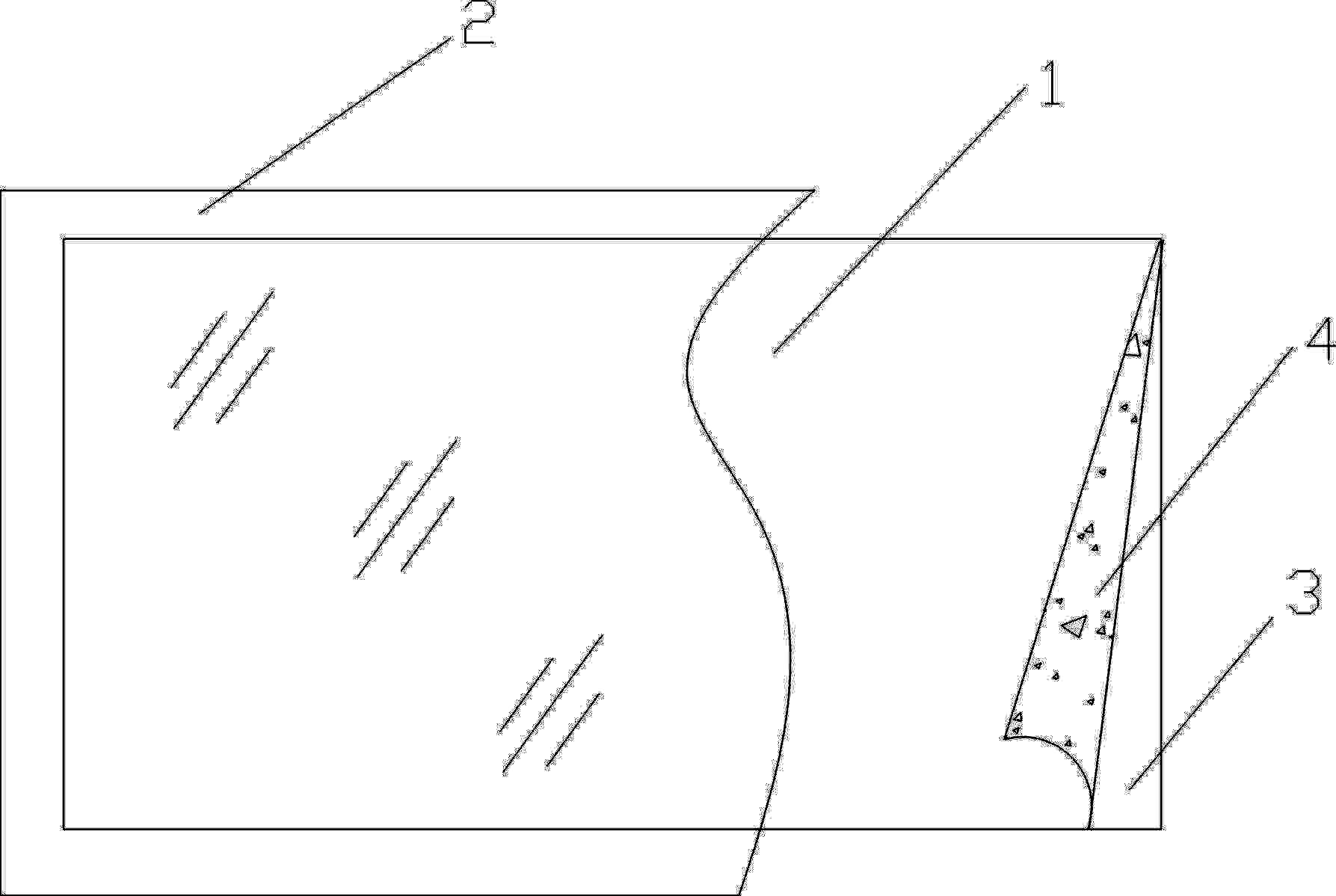

[0011] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. as the picture shows,

[0012] A sampling package for detecting salt density values of external electrical insulation equipment, mainly composed of a sampling wet tissue 1 and a sealed bag 2. The sampling wet tissue is composed of a non-woven wet tissue base 3 and a mildew-resistant layer 4 immersed on the surface of the base. Composition, the sampling wet wipes are placed in a sealed bag.

[0013] Using the sampling method of the sampling package for the detection of the salt density value of the external electrical insulation equipment above,

[0014] (1) Use the infiltration method to form a wet anti-mold layer on the surface of the non-woven fabric to make anti-mold sampling wet wipes, and put them in a sealed bag;

[0015] (2) At the work sampling site, the operator takes out the sampling wipes an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com