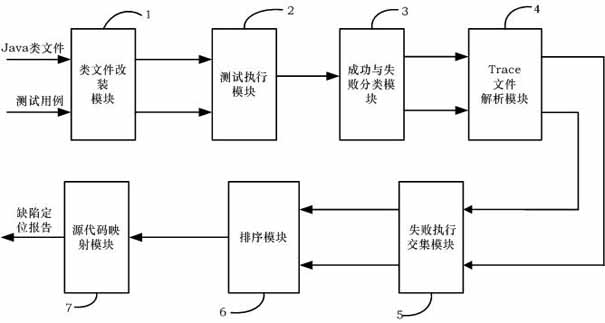

Defect automatic positioning device based on control flow intersection and automatic positioning method thereof

A technology of automatic positioning and control flow, applied in the direction of software testing/debugging, etc., can solve the problems of inconvenience, time-consuming and laborious troubleshooting, low accuracy of positioning defects, etc., to improve the efficiency of troubleshooting, improve the accuracy, and save manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

test Embodiment 2

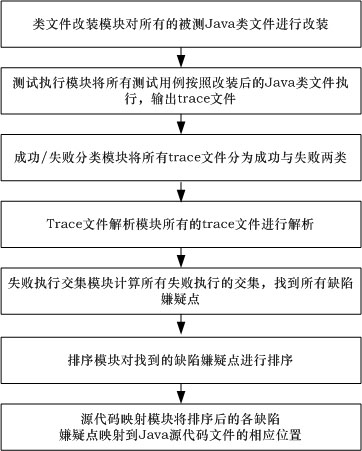

[0055] like Figure 5 As shown in the test cases, the trace files generated by use cases [1], [3], [4] are classified as successful trace files, and the trace files generated by test cases [2], [5], [6] are classified as failed A class of trace files.

[0056] Step 4: Trace file parsing module 4 parses the classified trace files in step 3, so that the parsed trace files can be identified and processed by subsequent modules. All trace information will be organized in a tree structure, where the root node of the tree is the test case information, and the branch and leaf nodes are the three types of program point information in step 1. The trace file generated by each test case is constructed as a corresponding tree data structure storage.

[0057] like Figure 7 As shown in the figure, the trace file generated by the test case [1] is parsed to form a tree structure, where the root node of the tree is the test case [1], and the branch and leaf nodes are the program point infor...

test Embodiment 2

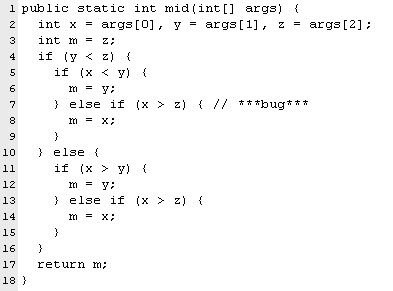

[0060] like Figure 8 As shown, the test cases [2], [5], and [6] are all failed cases, and the intersection of the test cases [2], [5], and [6] is obtained, as Figure 8 All defect suspects shown may contain defects, listed in Figure 8 In the "Suspect Points" column, the defect suspect points are: line 1, line 4, line 5, line 7, and line 14 of the program. It should be noted that the first line is regarded as the entry of the function mid(), and the 14th line is the return statement of the function mid(), both of which are added to the set of defect suspects.

[0061] Step 6: The sorting module 6 sorts the suspected defect points found in step 5 according to their frequency of occurrence in the successfully executed tree structure set from low to high. The numerical value of the frequency is a real number greater than or equal to 0 and less than or equal to 1, defined as: the number of times the defect suspect point appears in the successfully executed tree structure set / th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com