Method for predicting weld seam impact energy of Austenitic heat-resistant steel after aging at temperature of 650 DEG C

A technology of austenitic heat-resistant steel and impact energy, applied in the direction of measuring devices, special data processing applications, instruments, etc., can solve problems such as growing up, increasing the number of welded joints, and increasing maintenance costs, so as to avoid damage and avoid quantity Effects of increasing and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

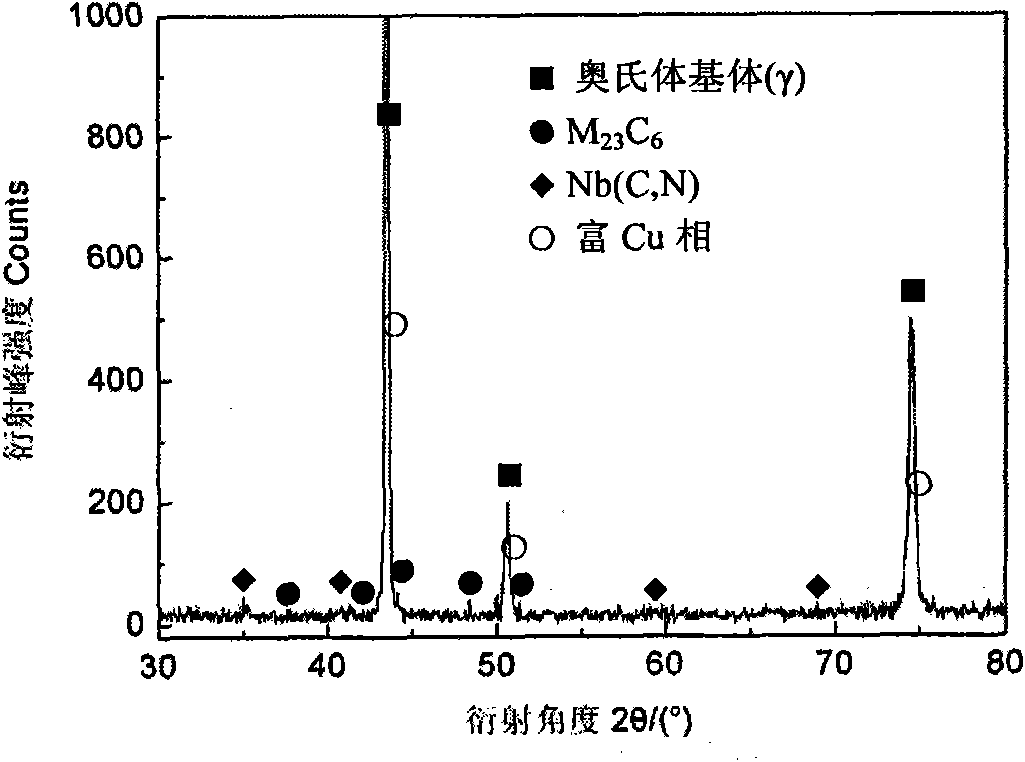

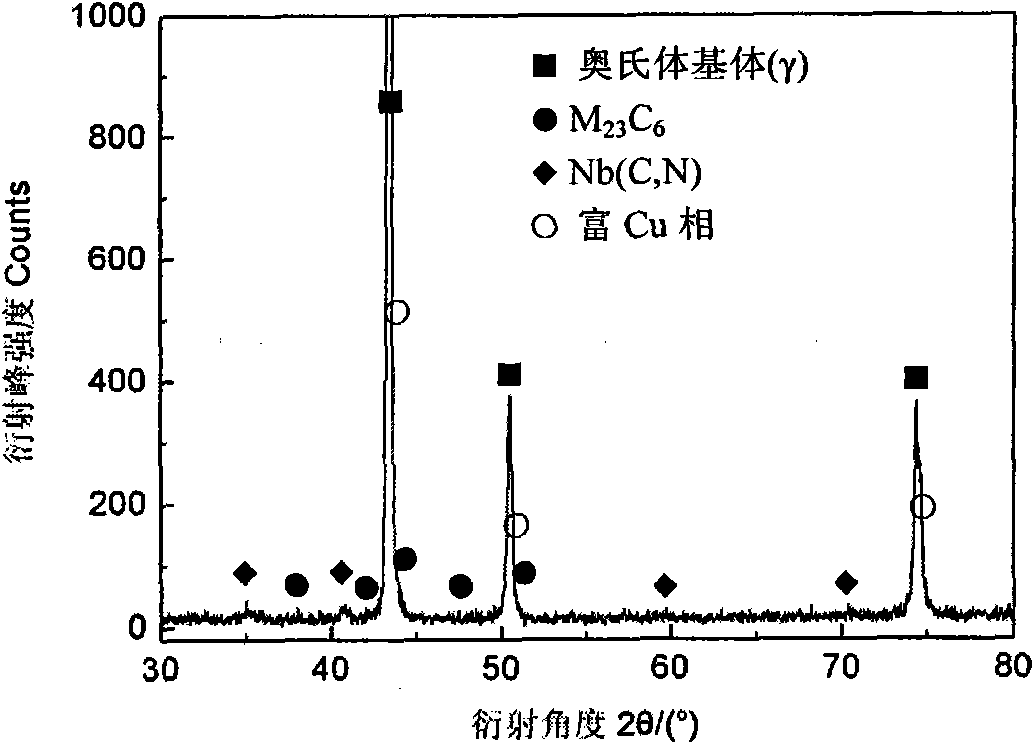

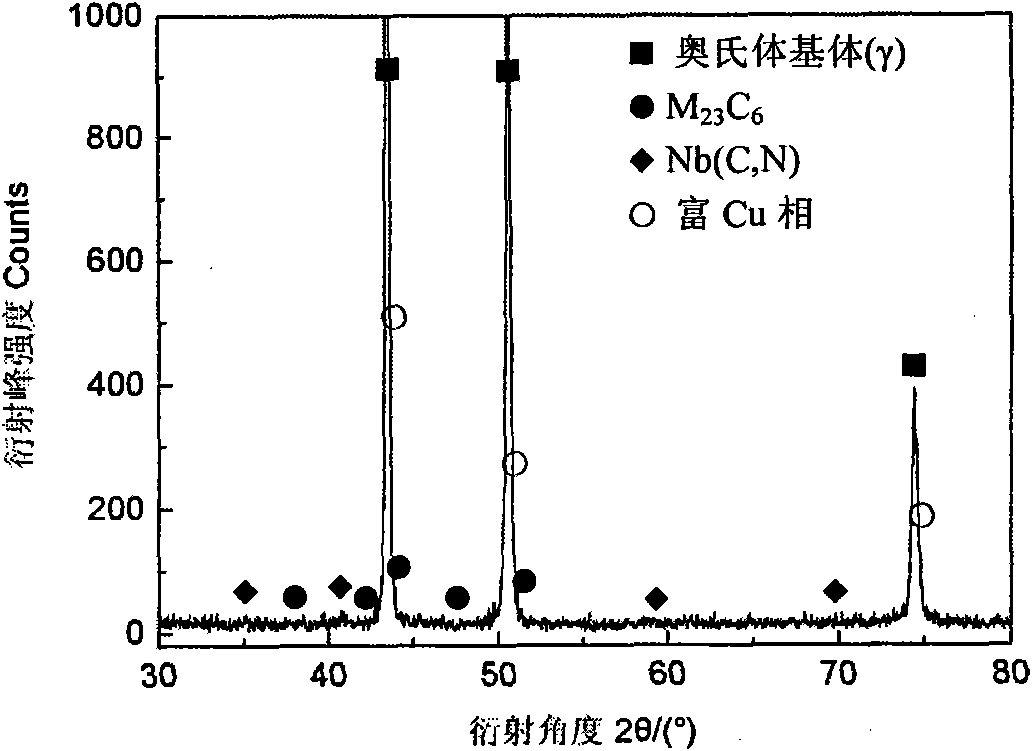

[0025] A method for predicting the impact energy of austenitic heat-resistant steel welds aged at 650°C:

[0026] A small weld seam sample is formed on the welded joint of the actual Super304H steel pipe. After running for 168 hours, the M in the metal structure of the weld seam sample is measured. 23 C 6 The relative precipitation amount M is 1.2985, which is substituted into the above quantitative relational formula: A KV =10.71+34.96e -M / 0.87 , can calculate and predict the specific value A of the impact energy of the weld metal KV The actual weld impact energy is 18.57J, the actual weld impact energy is 19.2J, and the deviation between the two is 3.28%. It can be seen that the predicted weld impact energy is relatively close to the measured value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com