Apparatus for detecting printing plates and a printing plate monitoring system for a printing press

A printing machine and printing plate technology, applied in the printing plate monitoring system, the existence of the printing plate installation position, and the printing plate field on the printing plate cylinder, can solve the problems of negative pressure, blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

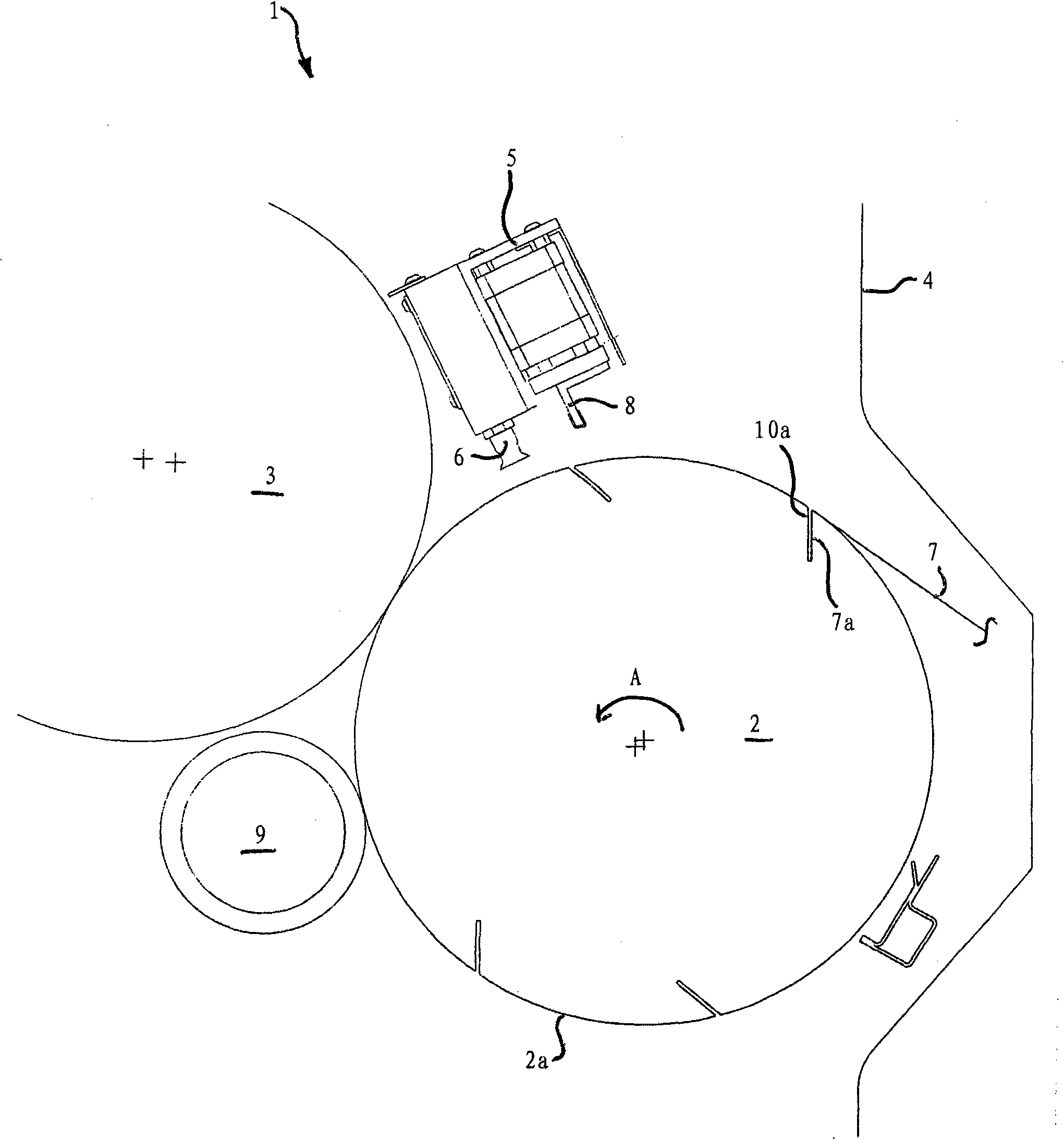

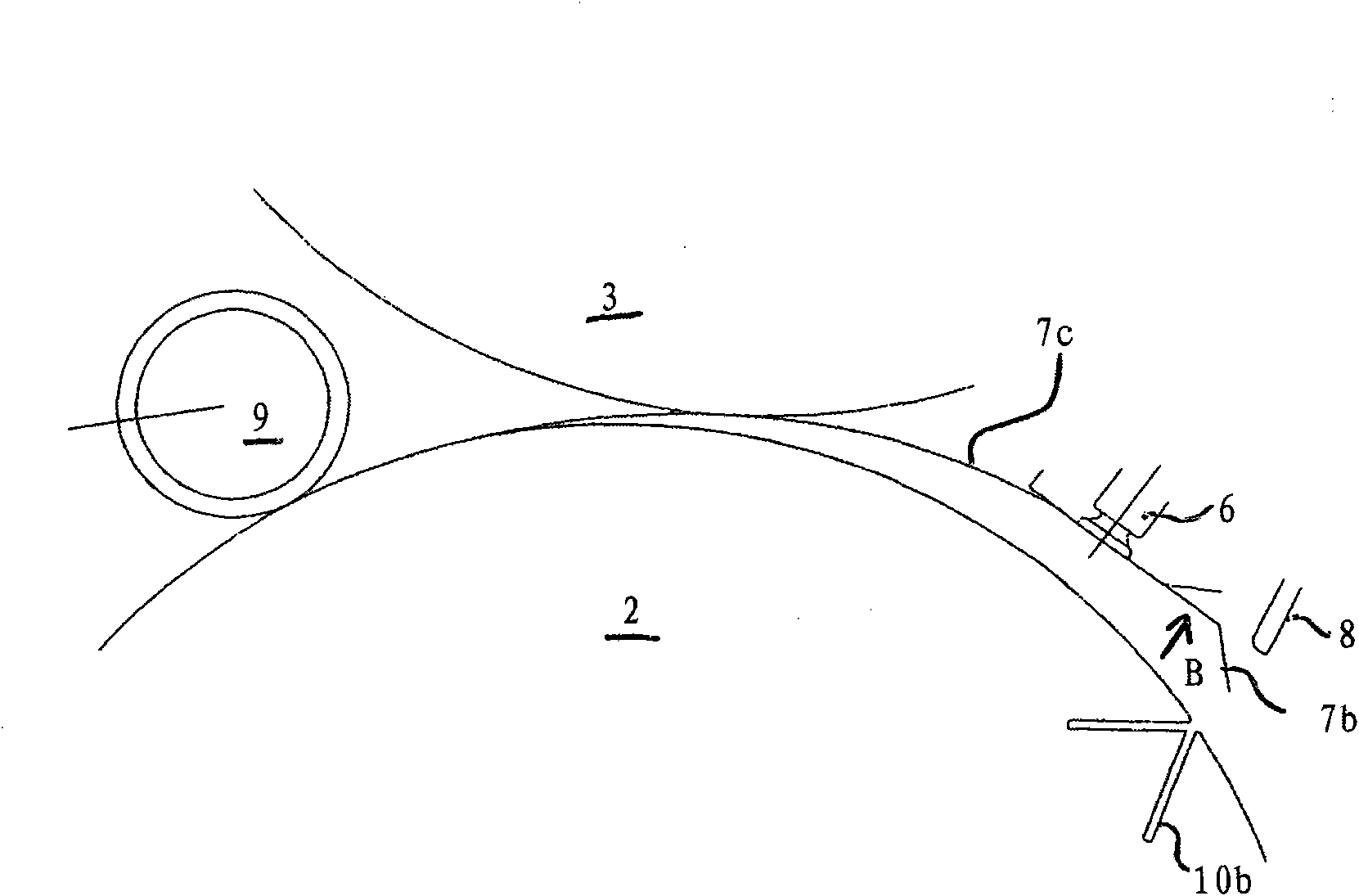

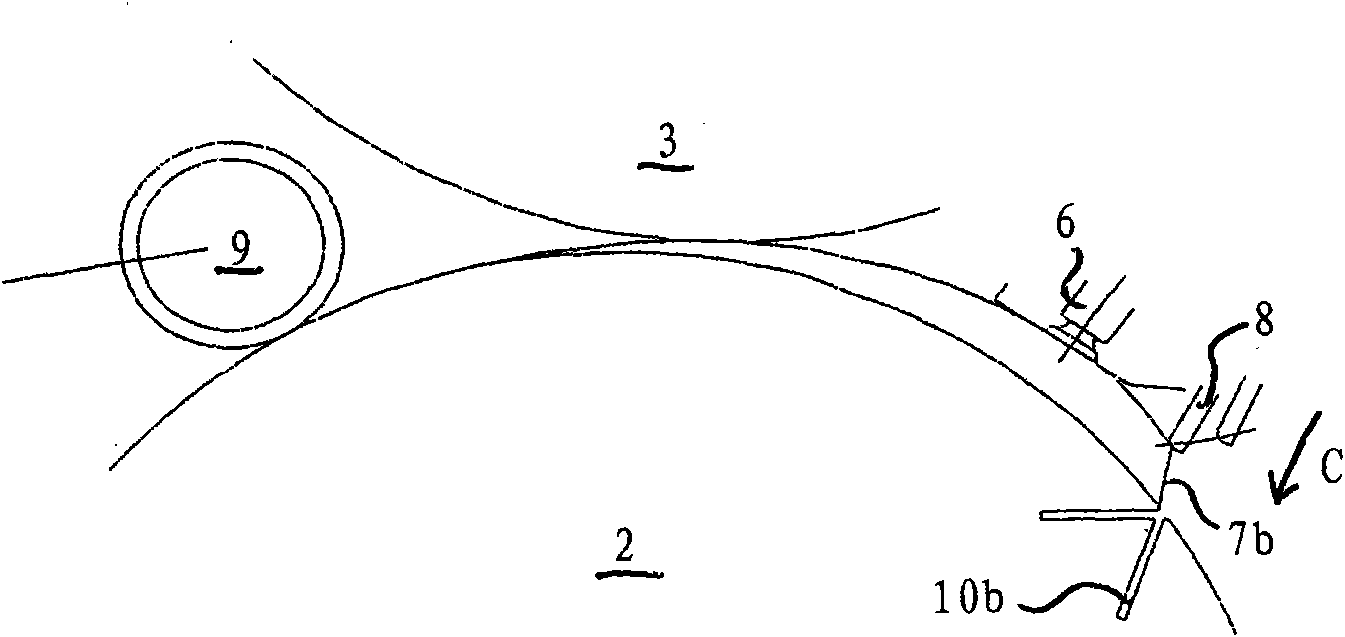

[0060] Referring now to the accompanying drawings, the figure 1 A side sectional view of part of a printing unit 1 of a rotary offset printing press according to an embodiment of the invention is shown in , showing the plate cylinders 2 of one cylinder group or printing group mounted within a frame 4 and the offset printing Roller 3. As mentioned above, each printing unit 1 of the printing press comprises a plurality of cylinder sets, but only one set is shown and specified. It will be appreciated that for a complete four roll printing tower, 8 sets of equipment are required, one for each printing group.

[0061]The device for detecting the presence of partially loaded printing plates in discrete plate mounting positions on the printing press plate cylinder 2 is integrated with a printing plate loading / unloading head 5 comprising a plurality of attraction elements 6 grouped into each plate position. Each set of attraction elements 6 is connected to a discrete vacuum circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com