Apparatus for washing and dewatering pulp

A technology for pulp and equipment, applied in pulp dewatering, pulp beating/refining method, washing/replacement of pulp treatment liquid, etc., can solve problems such as affecting accessibility and bulky, reduce the number of connection points, and benefit the site Installation, the effect that is conducive to equipment installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

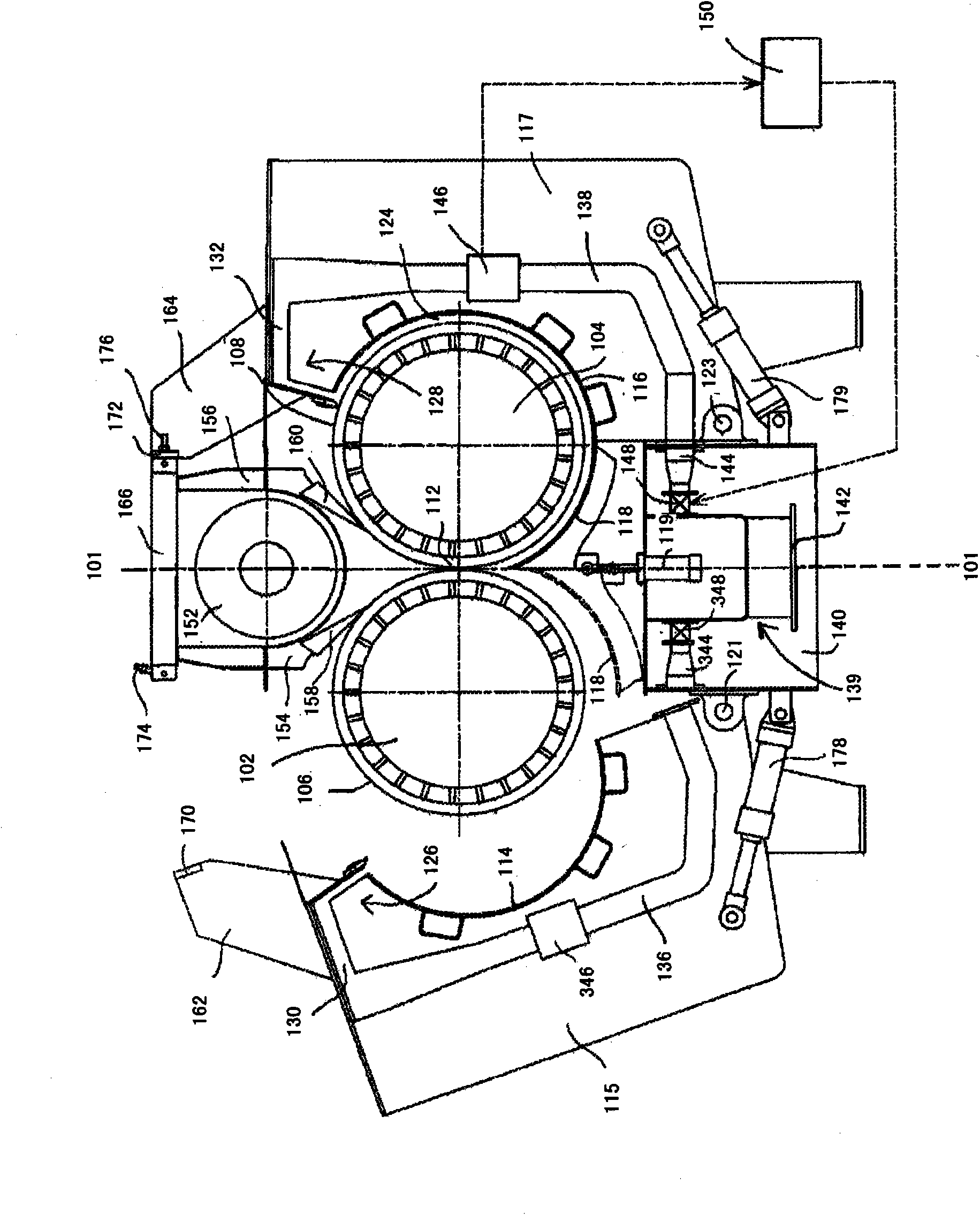

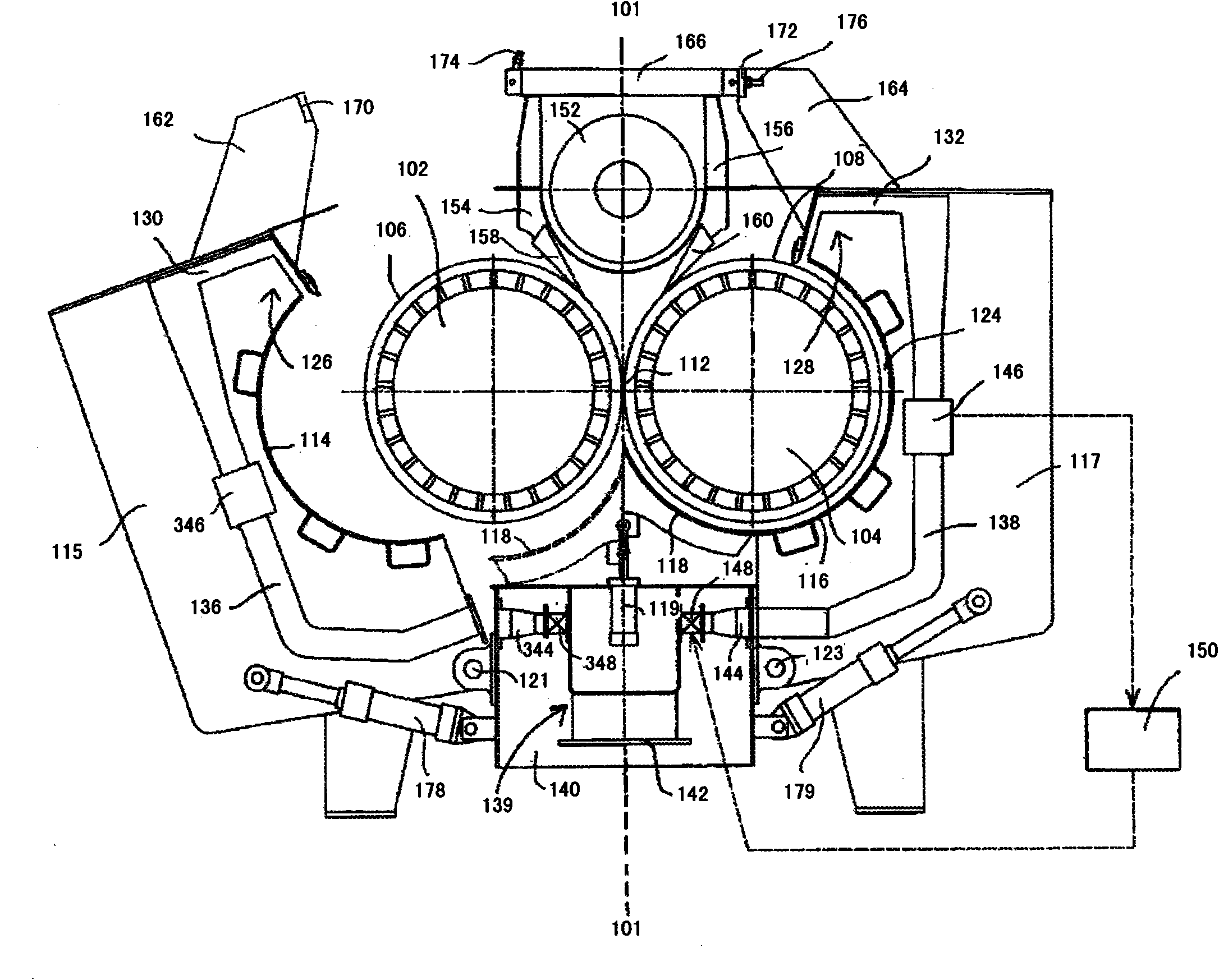

[0020] figure 1 An example of an apparatus for washing and dewatering cellulose-containing pulp according to the present invention is shown. The device has a basically symmetrical structure with respect to the plane of symmetry 101, in figure 1 , The left side of the device (ie, the left side of the symmetry plane 101) shows that the device is in the open position, and the right side of the device (ie, the right side of the symmetry plane 101) shows that the device is in the closed working position. The device includes a first rotatable press roll 102 located on the left side of the device and a second rotatable press roll 104 located on the right side of the device. Each press roll 102, 104 has a permeable outer surface 106, 108. The outer surfaces 106, 108 are porous, that is, provided with a plurality of holes, and the outer surfaces 106, 108 are permeable to the filtrate extruded from the pulp. The shape of the hole is usually circular, but it can take any shape. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com