Resistance generating device for magnetic control vehicle with squirrel cage rotor flywheel

A squirrel-cage rotor and generator technology, applied in sports accessories, muscle training equipment, gymnastics equipment, etc., can solve the problems of high failure rate, increased occlusal collision, high material cost, etc., to improve operating performance, reduce volume, The effect of saving material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In conjunction with the accompanying drawings, the present invention will be further described below.

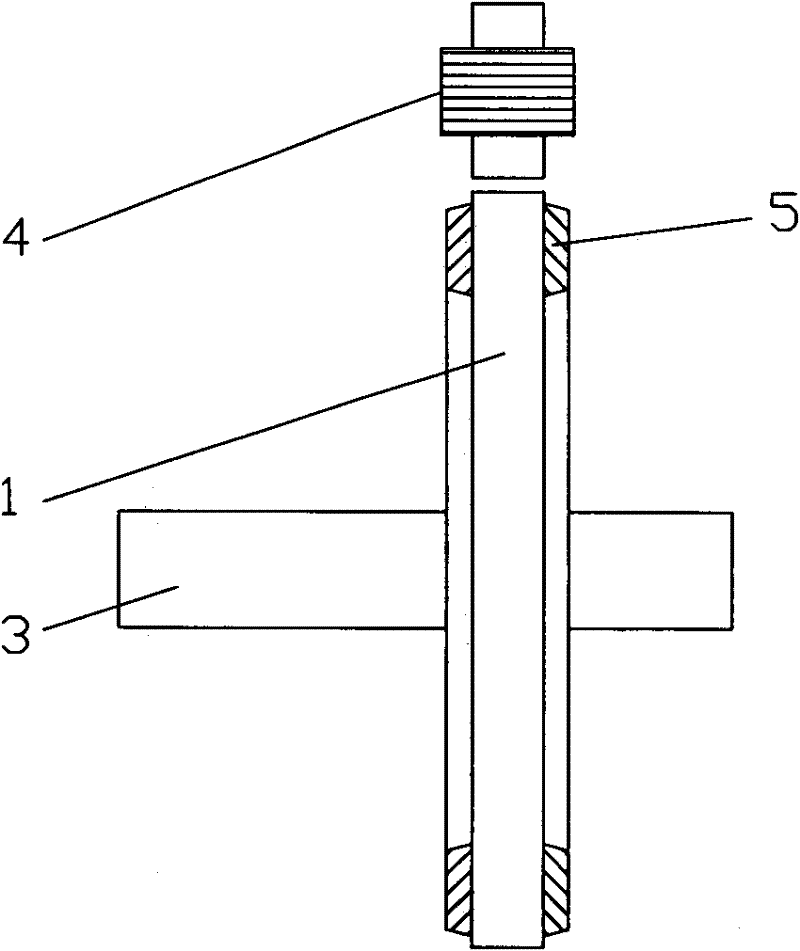

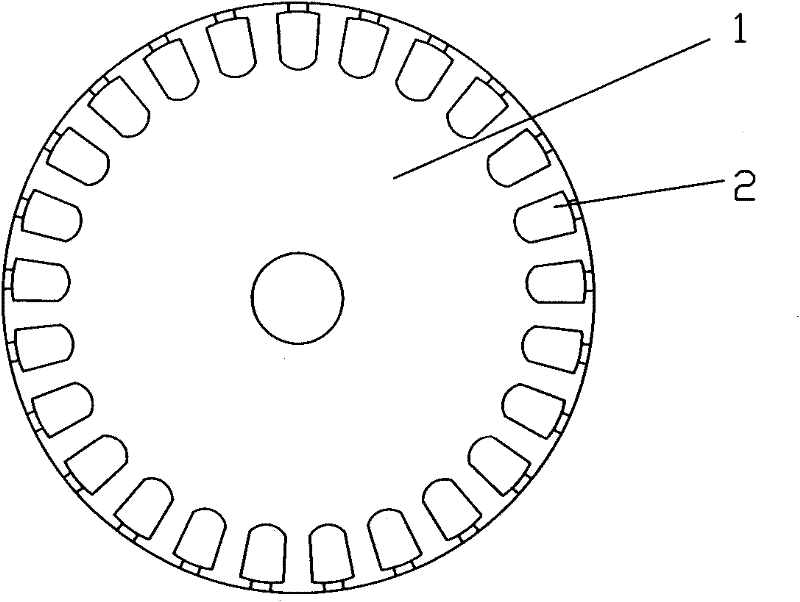

[0015] A resistance generating device for a magnetic control vehicle with a squirrel cage rotor flywheel, comprising a magnetically conductive flywheel 1, the magnetically conductive flywheel 1 is mounted on a support shaft 3 through a bearing, an electromagnet 4 is installed on the magnetically controlled vehicle frame, and the electromagnet 4 and the guide The relative position between the magnetic flywheels 1 satisfies the magnetic field produced by the cutting electromagnet 4 when the magnetic flywheel 1 rotates around the support shaft 3; 2 form a squirrel cage rotor. The distance between the farthest end of the squirrel cage bar 2 and the outer circle of the magnetic flywheel 1 is between 0-3mm. The two ends of the squirrel cage guide bar 2 are provided with an end ring 5 respectively, and the end ring 5 connects all the squirrel cage guide bars 2 . The squirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com