Fold, preparation method thereof, paper box and double-edge reverse-press cutting die

A carton and cardboard technology, used in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of affecting processing quality, deformation of hanging holes, and increased cost of carton materials, and achieves high qualified rate of finished products and reduced cost. small force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

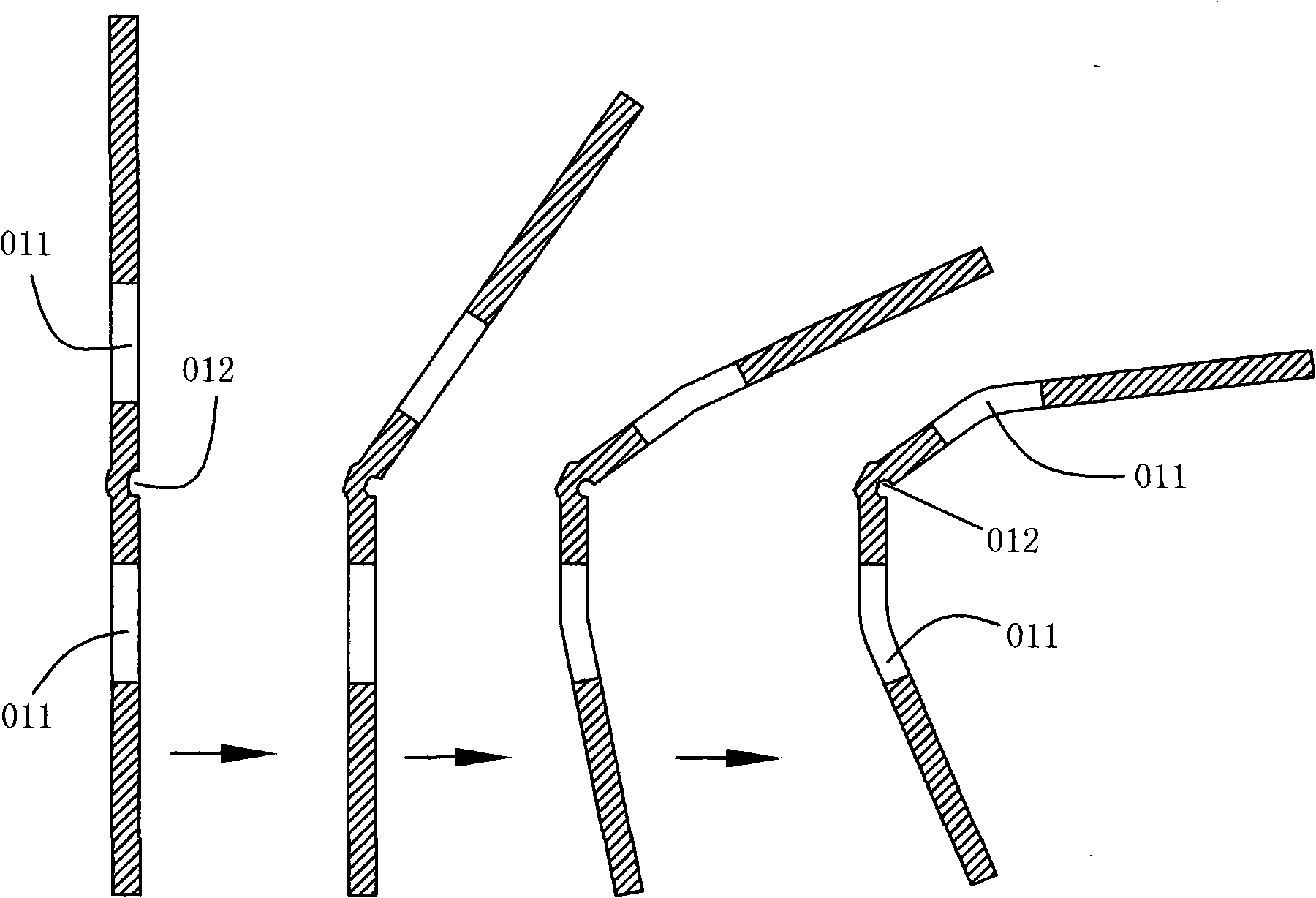

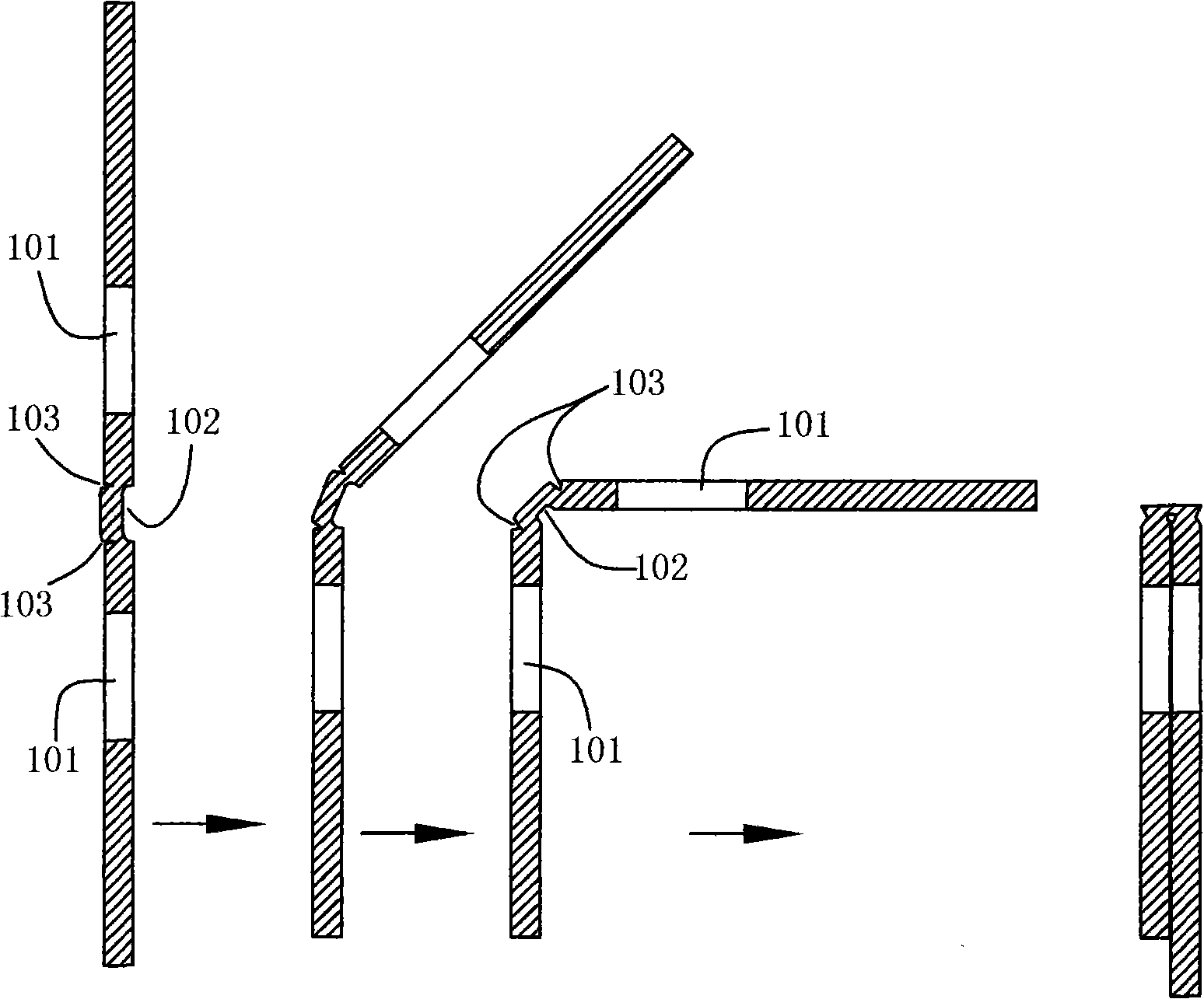

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings. refer to image 3 , the first embodiment of the present invention is a kind of crease, which is specially used for folding the cardboard after punching the head hole 101, including cardboard, the reverse side of the cardboard has an indentation 102, and the front side of the cardboard has two knife marks 103, two knife marks 103 The direction of the knife marks 102 is consistent with that of the indentation 102, and the positions of the two knife marks 103 correspond to the two edges of the indentation 102 respectively. In this embodiment, the depths of the two knife marks 103 are both half-cut, that is, 1 / 2 of the thickness of the cardboard.

[0023] The second embodiment of the present invention is a crease preparation method, which is used to prepare the creases described in the first embodiment of the present invention. The method includes the following st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com