Arrangement structure of copper wires in wire rewinding machine

A technology of wire take-up and copper wire, applied in the field of wire take-up, which can solve the problems of messy wires, increase the cost of downstream customers, storage and transportation of messy wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

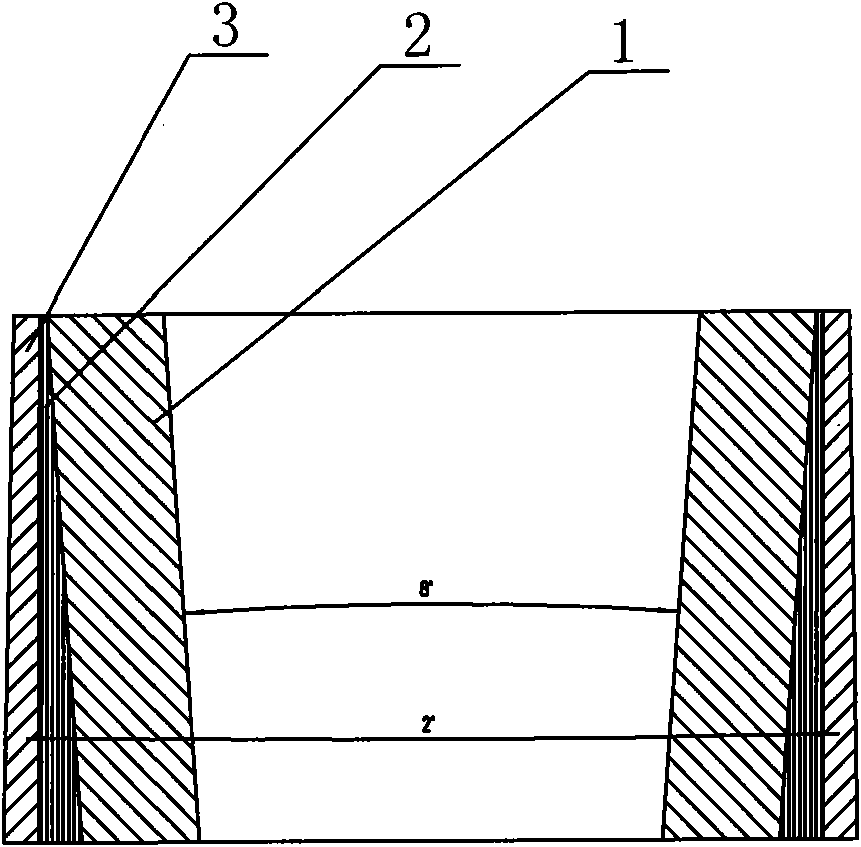

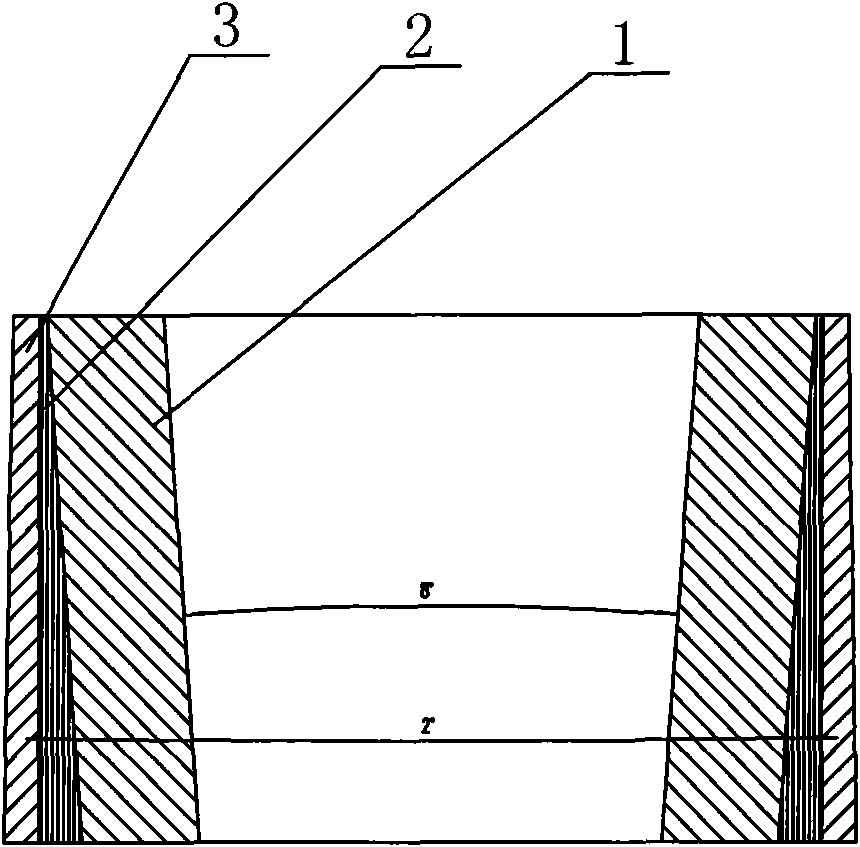

[0012] Such as figure 1 As shown, the arrangement structure of the copper wires in the wire take-up machine includes: an inner wire layer 1 inclined inward with a certain taper, and the vertebra angle of the inner wire layer 1 inclined inward is 6-10 degrees. In this embodiment, The inwardly inclined vertebra angle of the inner thread layer 1 is 8 degrees, the outer thread layer 2 is arranged outside the inner thread layer 1, the outer thread layer 2 is vertically arranged, and the outer thread layer 3 is arranged on the outer side of the inner thread layer 2 The outer thread layer 3 is inclined outward by a certain taper, and the outer thread layer 3 has a taper of 1 to 3 degrees. In this embodiment, the outer thread layer 3 has an outward taper of 2 degrees.

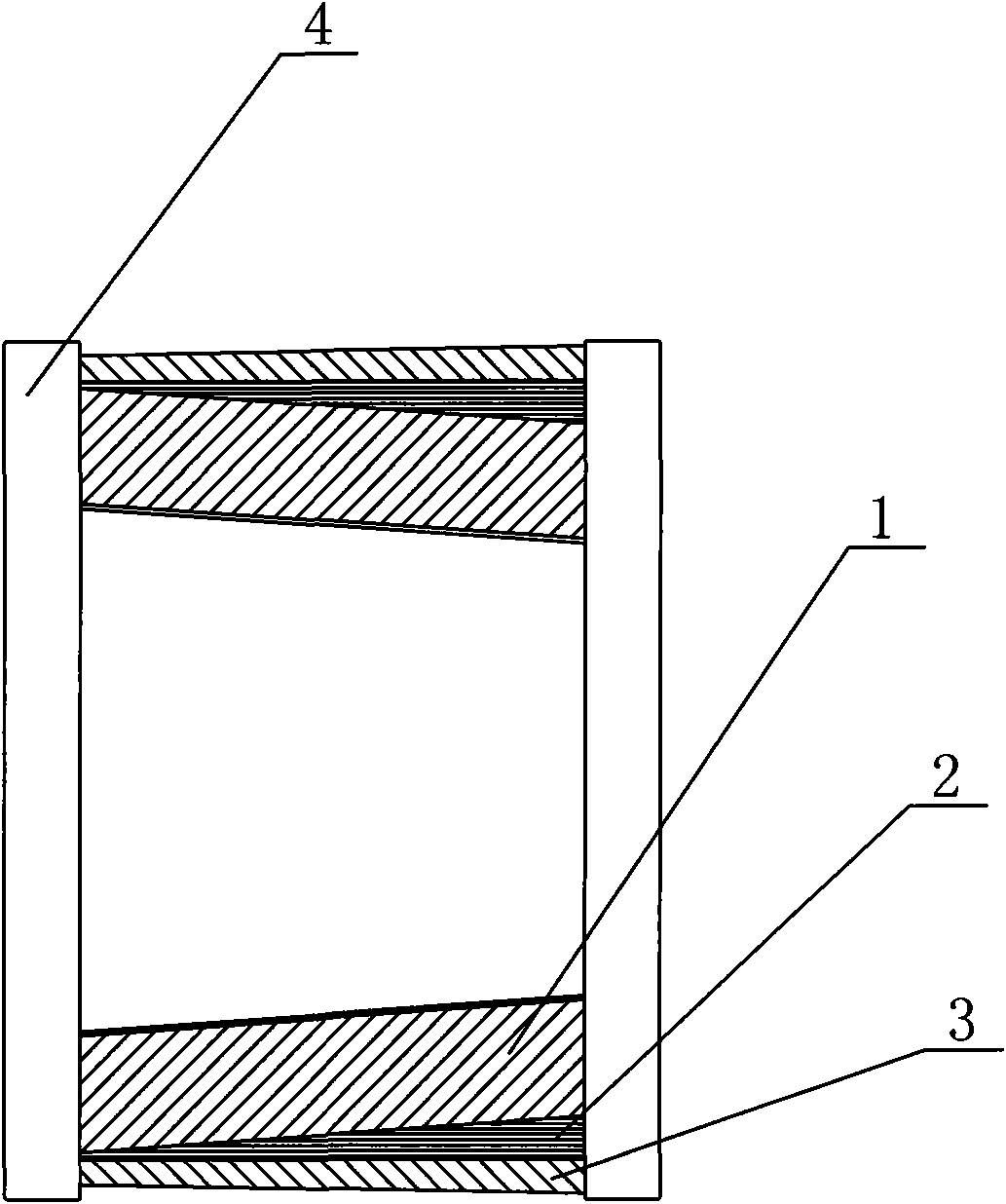

[0013] Such as figure 2 As shown, the copper wires are arranged sequentially on the wire tray 4 through the automatic calculation and control system. The process of arranging the wires is divided into three stages. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com