Group directional glass bulb evaporation device

An evaporation and glass bulb technology, which is applied in the field of group directional glass bulb evaporation equipment to achieve the effect of avoiding pollution and high evaporation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

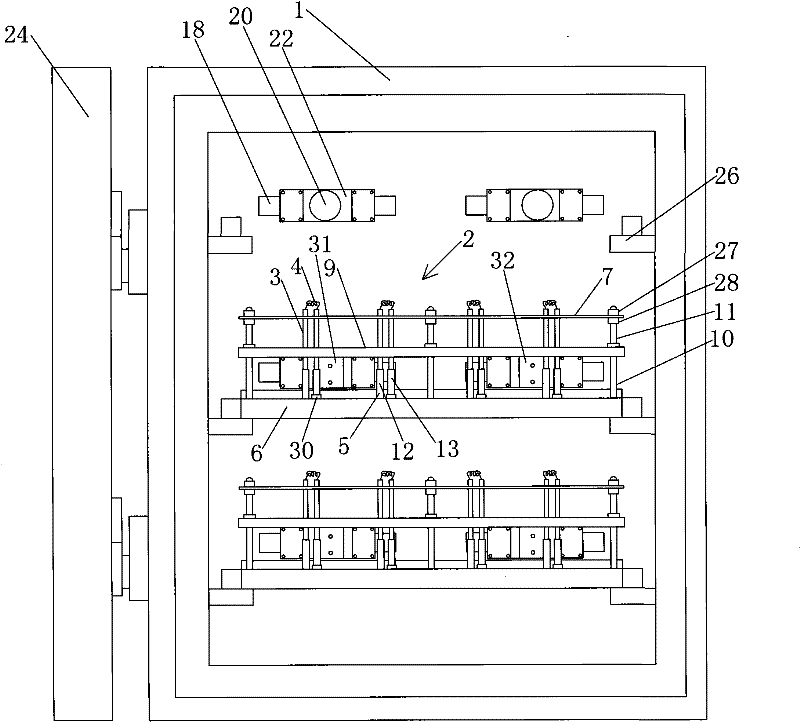

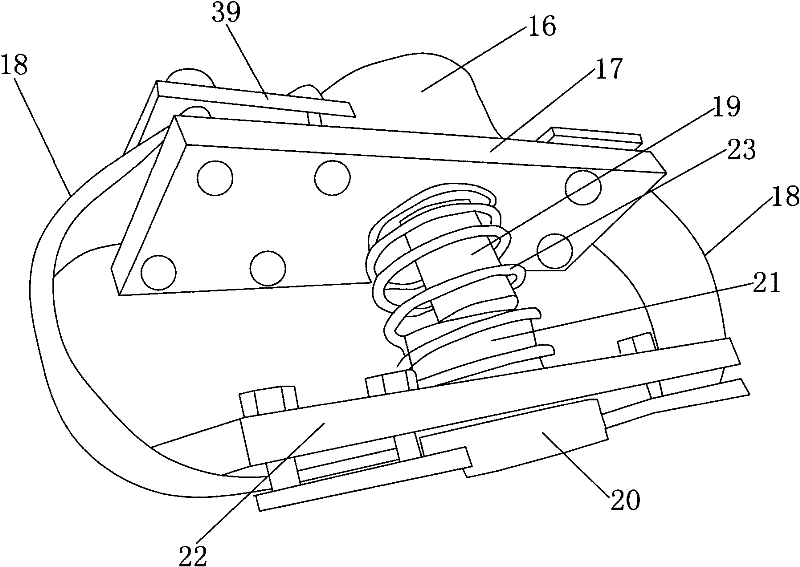

[0026] Example: such as figure 1 As shown, the group oriented glass bulb evaporation equipment includes a vacuum chamber 1 and a door body 24. In the vacuum chamber 1, multi-layer slide rails 26 are arranged from top to bottom, and an evaporation tray is arranged on each layer of slide rails 26. Frame 2, on the evaporation bracket 2, there are many pairs of vertically placed electrode rods 3, the upper ends of the electrode rods 3 are connected with heating wires 4, and a shielding screen (not shown in the figure) is arranged outside the heating wire 4. Regarding the shielding For the specific structure of the screen, please refer to the applicant's invention patent "A glass bulb aluminum evaporation device for vacuum chamber", the patent number is: 93223439.9.

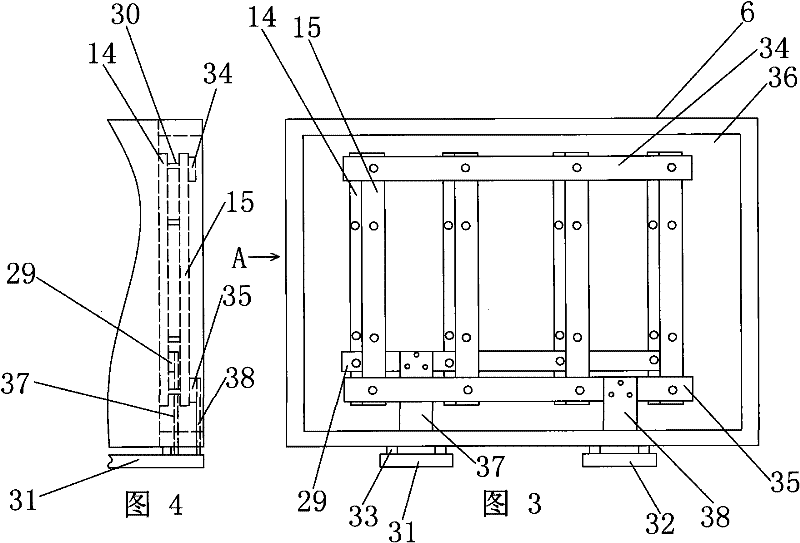

[0027] The overall structure of the evaporation bracket 2 is as follows. It includes a base 6 on which a plurality of connectors 5 are arranged. The lower end of the electrode rod 3 is plugged into the connectors 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com