Oil free screw compressor

A compressor and oil screw technology, applied in the field of oil-free screw compressors, can solve the problems of high energy efficiency and high electricity costs, and achieve the effect of suppressing the increase in power consumption and preventing over-compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

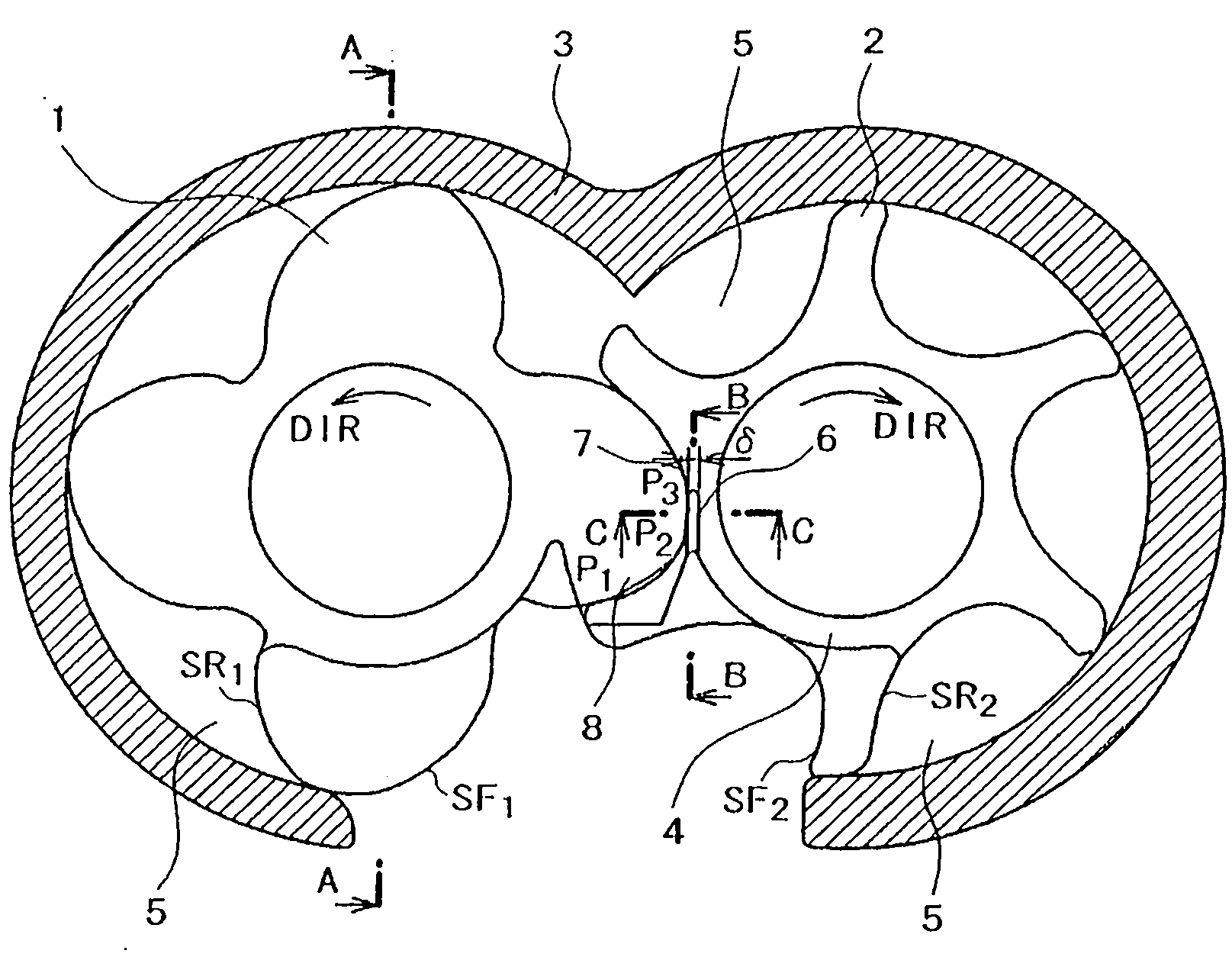

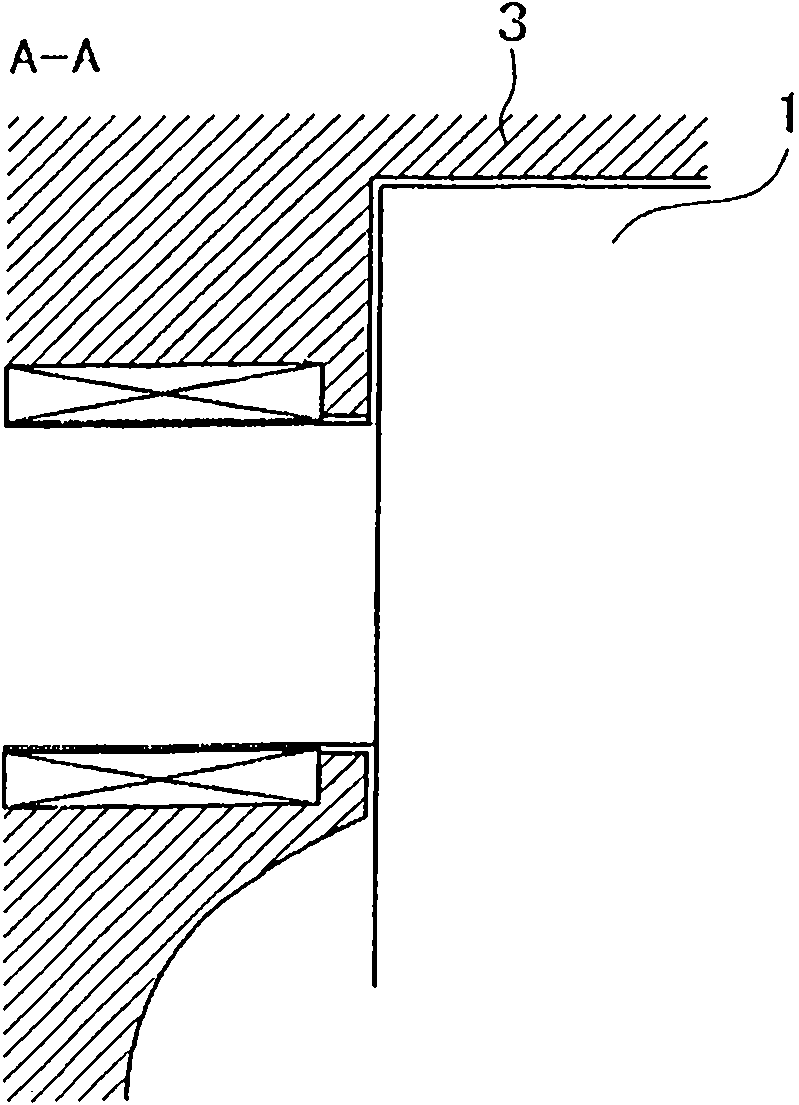

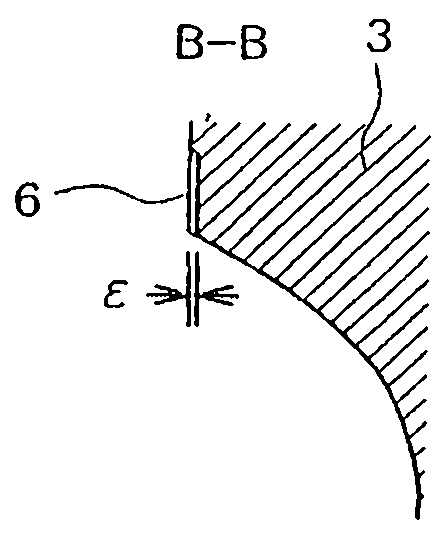

[0034] Hereinafter, an embodiment of the oil-free screw compressor of the present invention will be described with reference to the drawings. First, refer to Figure 5 An overview of oil-free screw compressors will be described. Figure 5 (a) is a top sectional view of the oil-free screw compressor 50, Figure 5 (b) is a front sectional view. The oil-free screw compressor 50 has a pair of male screw rotor 1 and female screw rotor 2 , and the pair of rotors 1 , 2 are accommodated in a chamber formed in the casing 3 . The chamber is formed by connecting two cylindrical spaces in a direction at right angles to the axial direction, and their axes are parallel to each other.

[0035] One shaft end of each rotor 1 , 2 is rotatably supported by bearings 11 , 12 , and the other shaft end is rotatably supported by bearings 13 , 14 . Bearings 11 to 14 are held on housing 3 . Lubricating oil is supplied to the bearings 11-14. Since the screw compressor 50 of the present invention i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap