A Rotating Blade Arrangement for Improving the Aerodynamic Performance of Axial Flow Compressor

An axial flow compressor and rotating blade technology, which is applied to machines/engines, components of pumping devices for elastic fluids, mechanical equipment, etc., can solve the problems of limited improvement of turning angle and increased flow loss at design points, etc. Achieve the effect of not reducing aerodynamic stability, improving flow conditions, and improving aerodynamic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

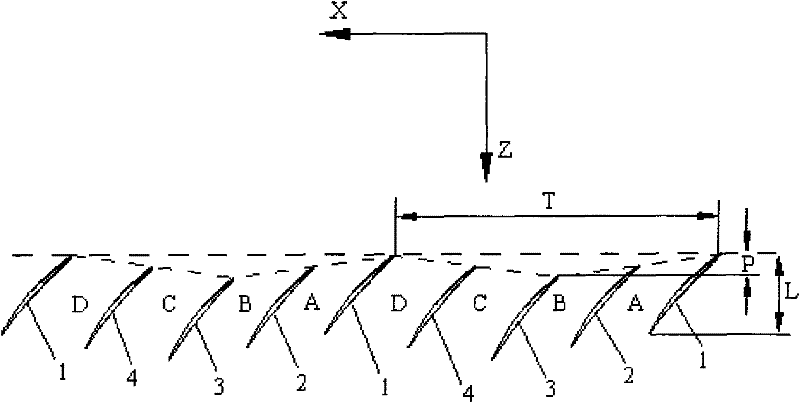

[0029] The arrangement of blades in the rotating blade row of the present embodiment is as follows: take N=2, and in the circumferential direction X of the blade row, a blade group is formed by 5 adjacent blades, and the fifth blade is the blade group in the next blade group. The first blade 1; in the same blade group, the second blade 2 is located on the side of the back surface of the first blade 1, the third blade 3 is located on the side of the back surface of the second blade 2, and the fourth The first blade 4 is positioned on the side of the blade back surface of the third blade 3, the first blade 1 is positioned on the side of the blade back surface of the fourth blade 4 in the previous blade group, and so on. The Z position of the compressor axial direction of the leading edge of each blade in a blade group forms a triangular wave, the leading edge of the first blade 1 in the blade group is located at the crest of the triangular wave, and the leading edge of the third ...

Embodiment 2

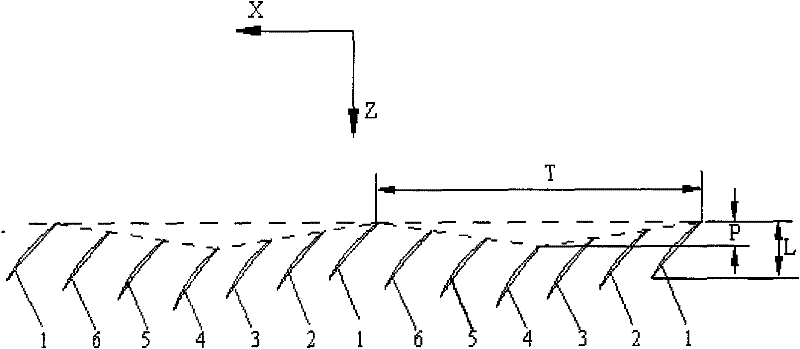

[0032] The arrangement of blades in the rotating blade row of this embodiment is as follows: take N=3, and in the circumferential direction X of the blade row, a blade group is formed by 7 adjacent blades, and the seventh blade is the blade group in the next blade group. The first blade 1; in the same blade group, the second blade 2 is located on the side of the back surface of the first blade 1, the third blade 3 is located on the side of the back surface of the second blade 2, and the fourth The first blade 4 is positioned at the blade back surface side of the third blade 3, the fifth blade 5 is positioned at the blade back surface side of the fourth blade 4, and the sixth blade 6 is positioned at the blade back surface side of the fifth blade 5. side, the first blade 1 is located on the side of the back surface of the fourth blade 6 in the previous blade group, and so on. The Z position of the compressor axial direction of the leading edge of each blade in a blade group for...

Embodiment 3

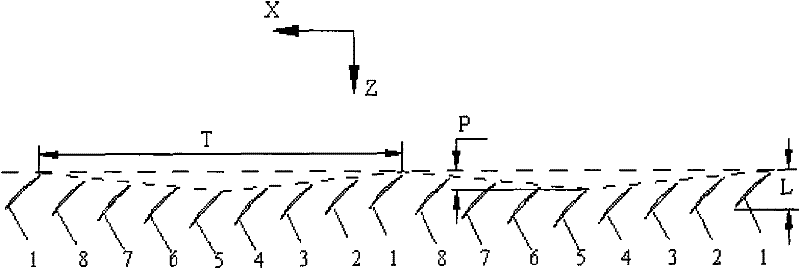

[0035] In this embodiment, the arrangement of the blades in the rotating blade row is as follows: take N=4, and in the circumferential direction X of the blade row, a blade group is formed by 9 adjacent blades, and the ninth blade is the blade group in the next blade group. The first blade of 1. In the same blade group, the second blade 2 is located on the side of the blade back surface of the first blade 1, the third blade 3 is located on the side of the blade back surface of the second blade 2, and the fourth blade 4 is located on the side of the blade back surface of the first blade 1. The blade back surface side of three blades 3, the fifth blade 5 is positioned at the blade back surface side of the fourth blade 4, the sixth blade 6 is positioned at the blade back surface side of the fifth blade 5, and the seventh blade 6 is positioned at the blade back surface side of the fifth blade 5. The blade 7 is located on the side of the blade back surface of the sixth blade 6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com