Oil consumption flowmeter of diesel engine

A diesel engine and flowmeter technology, applied in indirect mass flowmeters, volume/mass flow rate generated by mechanical effects, mass flow measurement devices, etc., can solve the problems of inability to eliminate errors and troubles, achieve high measurement accuracy, and realize informatization Effectiveness of monitoring and verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

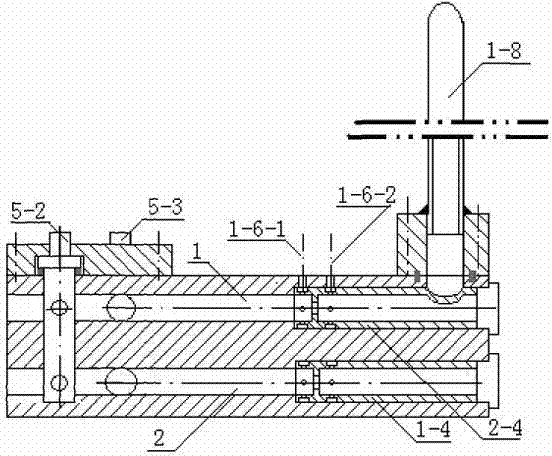

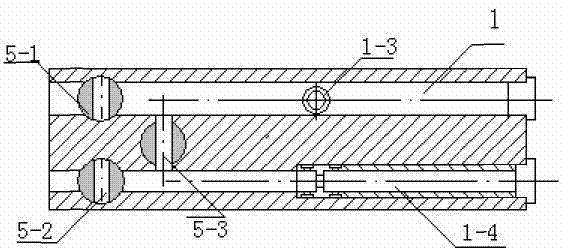

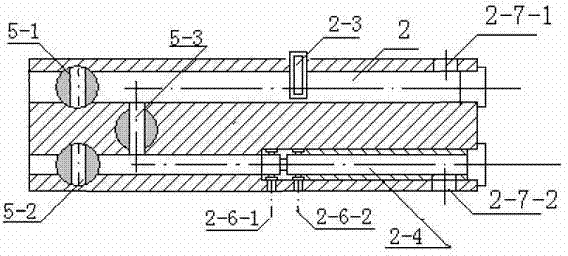

[0021] Such as figure 1 , Figure 4 , Figure 5 , Figure 7 , the present invention adopts two channels, one oil inlet channel 1 and the other oil return channel 2; orifice throttling devices (sleeves with orifice plates 1-4, 2-4,) are respectively provided in these two channels and pressure pilot holes 1-6-1, 1-6-2 and 2-6-1, 2-6-2 (see figure 2 , image 3 ); Two sensors 1-6-3 and 2-6-3 capable of measuring positive and negative differential pressure are installed on the pressure guide hole, so that each pipe can measure both forward flow and backflow; oil inlet channel 1 The difference with the forward flow of oil return channel 2 is the fuel consumption. In addition, two temperature sensors 1-3 and 2-3 are used to measure the oil temperature of the two channels respectively, so that the actual density of the oil inlet channel 1 and the oil return channel 2 can be known, and the respective mass flow rates can be measured, so that the The flow rate is used to calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com