Processing box and imaging device

A technology for processing boxes and imaging devices, which is applied in the fields of electrography, optics, instruments, etc. It can solve the problems of difficult positioning accuracy, simple assembly process, and poor positioning accuracy of imaging devices, so as to achieve simple guiding actions and reduce product costs. , The effect of simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

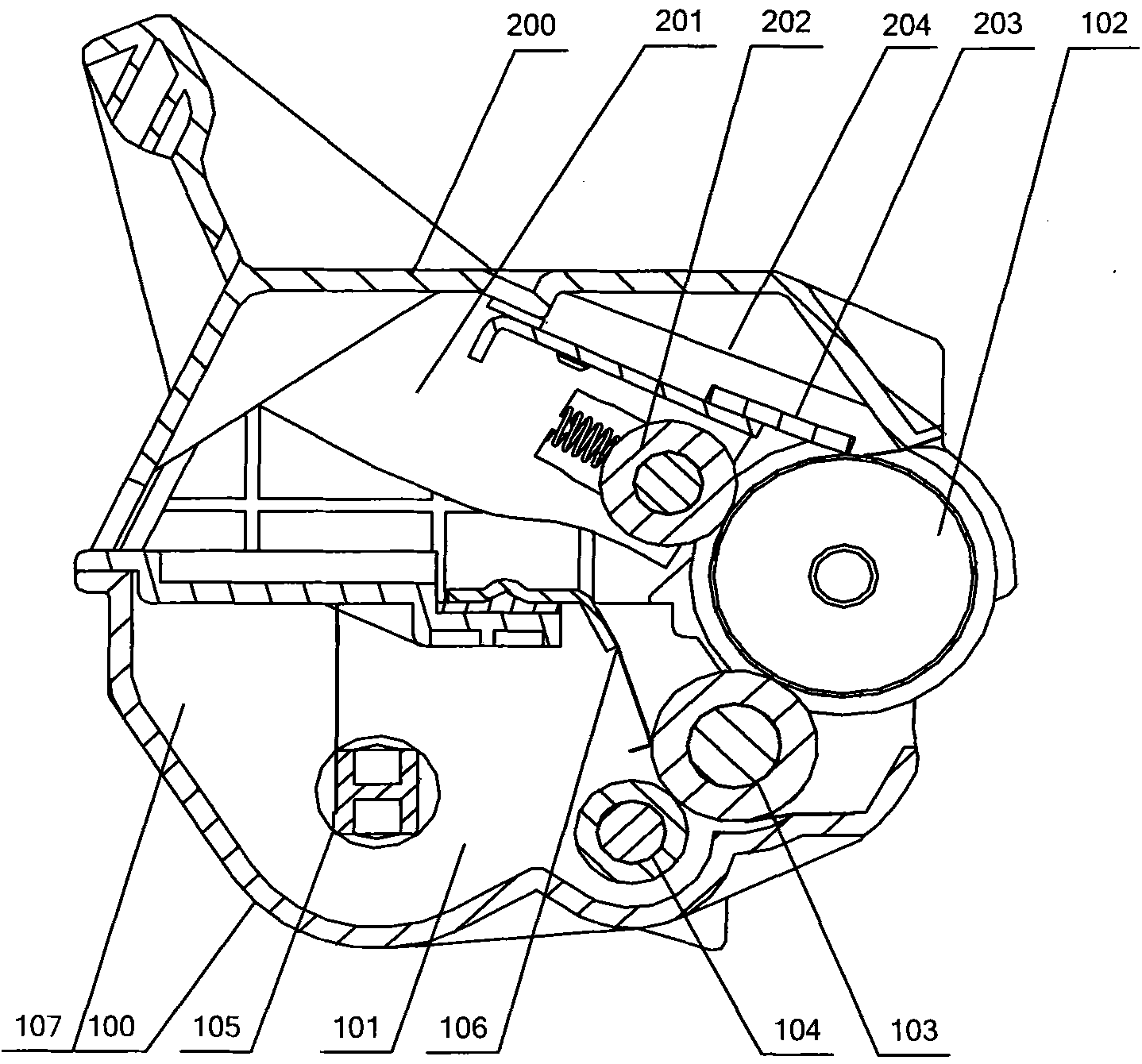

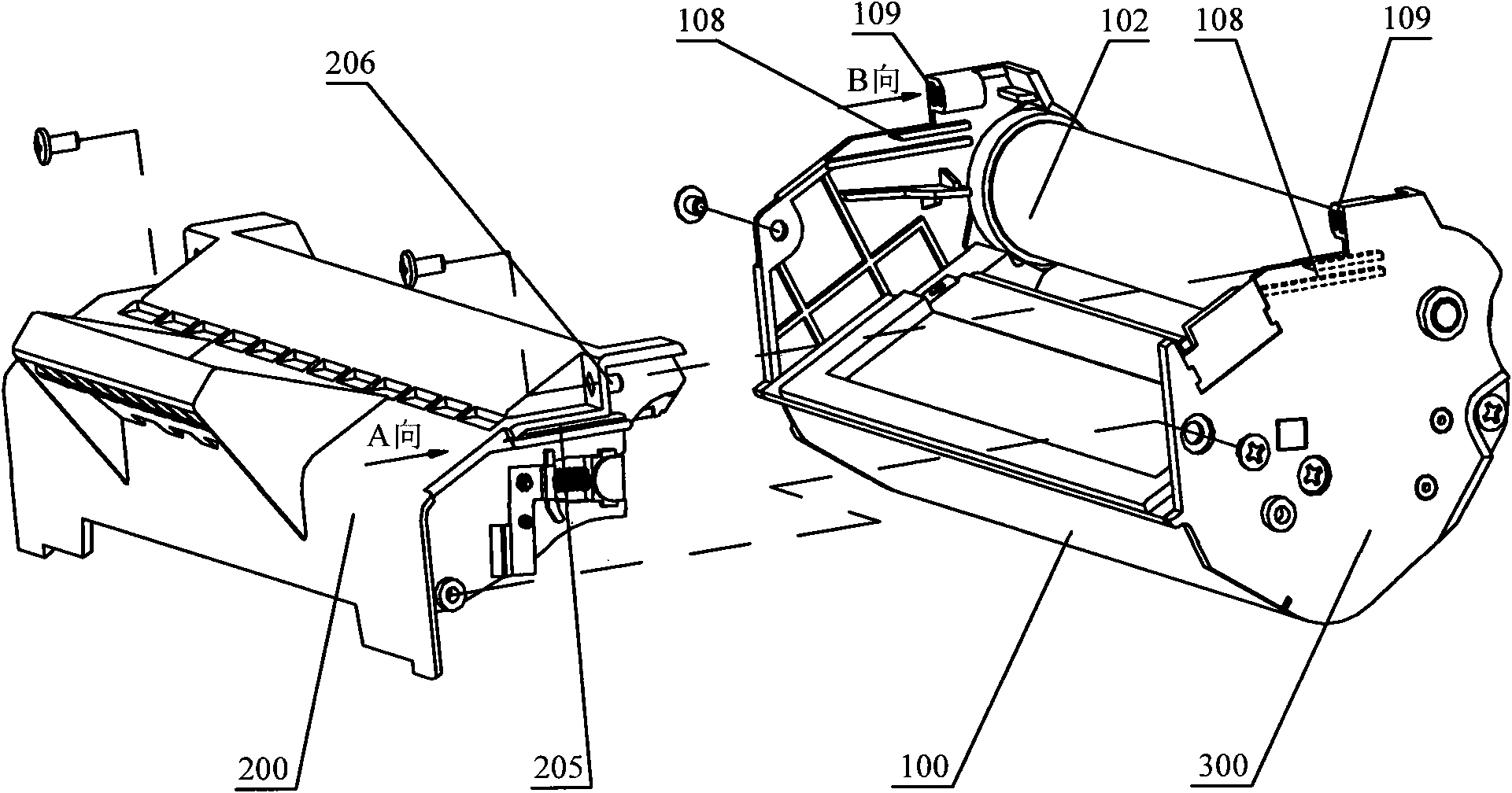

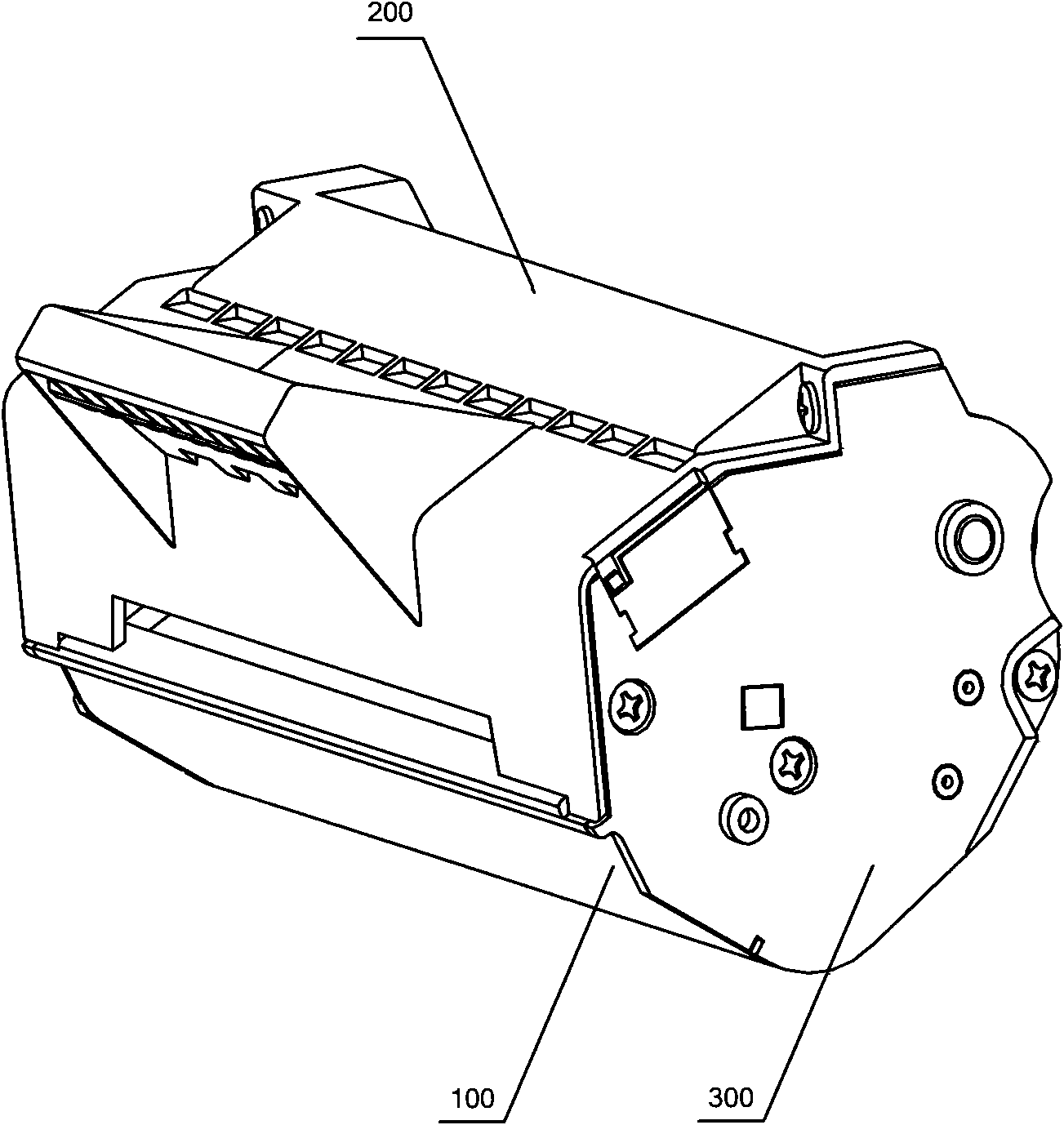

[0040] figure 1 It is a schematic diagram of the side sectional structure of the process box provided by Embodiment 1 of the present invention, figure 2 for figure 1 Schematic diagram of the disassembled state structure of the process box, image 3 for figure 1 Schematic diagram of the assembly state structure of the process box, Figure 4 for figure 1 Schematic diagram of the end cover structure of the middle process box, Figure 5 for figure 1 Schematic diagram of the shell structure of the waste toner bin of the middle process box. In this embodiment, a process box with a typical structure is taken as an example for illustration, as Figure 1-5 As shown, the process cartridge includes a developing chamber casing 100, an end cover 300, a waste toner chamber casing 200, and an imaging device arranged in the developing chamber 101 and the waste toner chamber 201, and the end cap 300 is vertically buckled on the developing chamber casing. The two ends of the body 100 f...

Embodiment 2

[0053] Image 6 It is a schematic diagram of the structure of the disassembled state of the process cartridge provided in Embodiment 2 of the present invention. The positioning assembly in this embodiment is a positioning convex surface 207 and a positioning concave surface 110 that abut against each other, and the direction in which the positioning convex surface 207 and the positioning concave surface 110 abut against each other as the second direction.

[0054] like Image 6 As shown, in this embodiment, what plays a role in positioning is the stepped plane that cooperates with each other. The stepped plane is preferably arranged at the end of the guiding stroke of the guide assembly. The positioned concave and convex surfaces can not only achieve abutting positioning in the second direction, but also In the axial direction of the photosensitive drum 102, the relative position between the main frame and the waste toner box housing 200 can be restricted. At this time, the ...

Embodiment 3

[0056] Figure 7 It is a schematic structural diagram of the disassembled state of the process cartridge provided by Embodiment 3 of the present invention. This embodiment provides an assembly method of the process cartridge. In this assembly method, the guide assembly is a stepped plane that cooperates with each other, and can be The guide main frame is assembled with the waste toner bin housing 200 .

[0057] The guide assembly in this embodiment is a guiding convex surface 209 and a guiding concave surface 112 that are slidably matched with each other, and the direction in which the guiding convex surface 209 and the guiding concave surface 112 slide against each other is taken as the first direction.

[0058] like Figure 7 As shown, the guiding function in this embodiment is the step-like plane that cooperates with each other. The step-like plane is preferably set at the end of the waste toner bin housing 200 and the main frame. The positioning protrusion 206 and the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com