Antiskid driver

A transmission and anti-skid technology, which is applied in the traditional field of wheeled vehicles, can solve problems such as wheel slippage and the ability to pass through cannot meet the demand, and achieve the effect of reliable power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

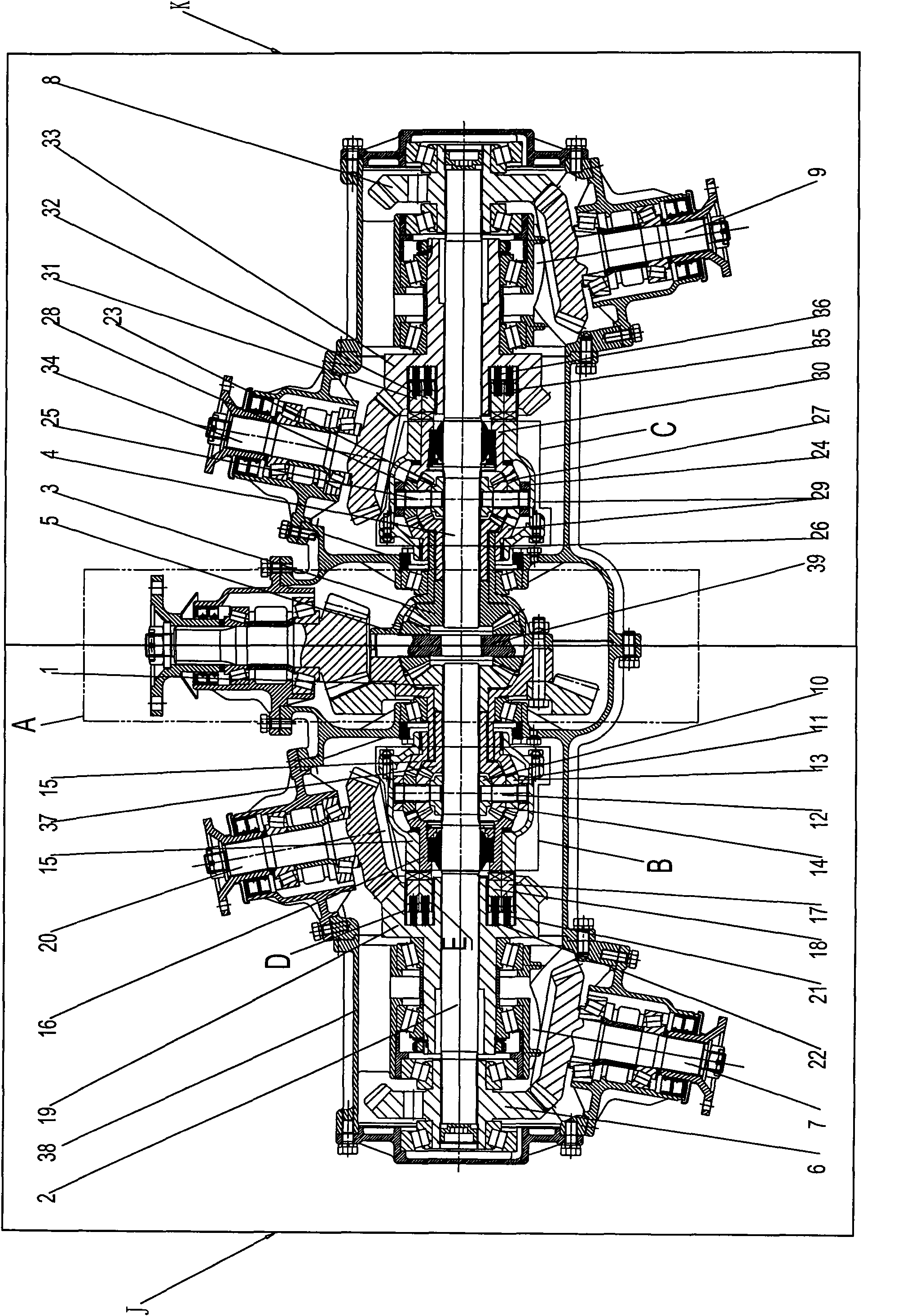

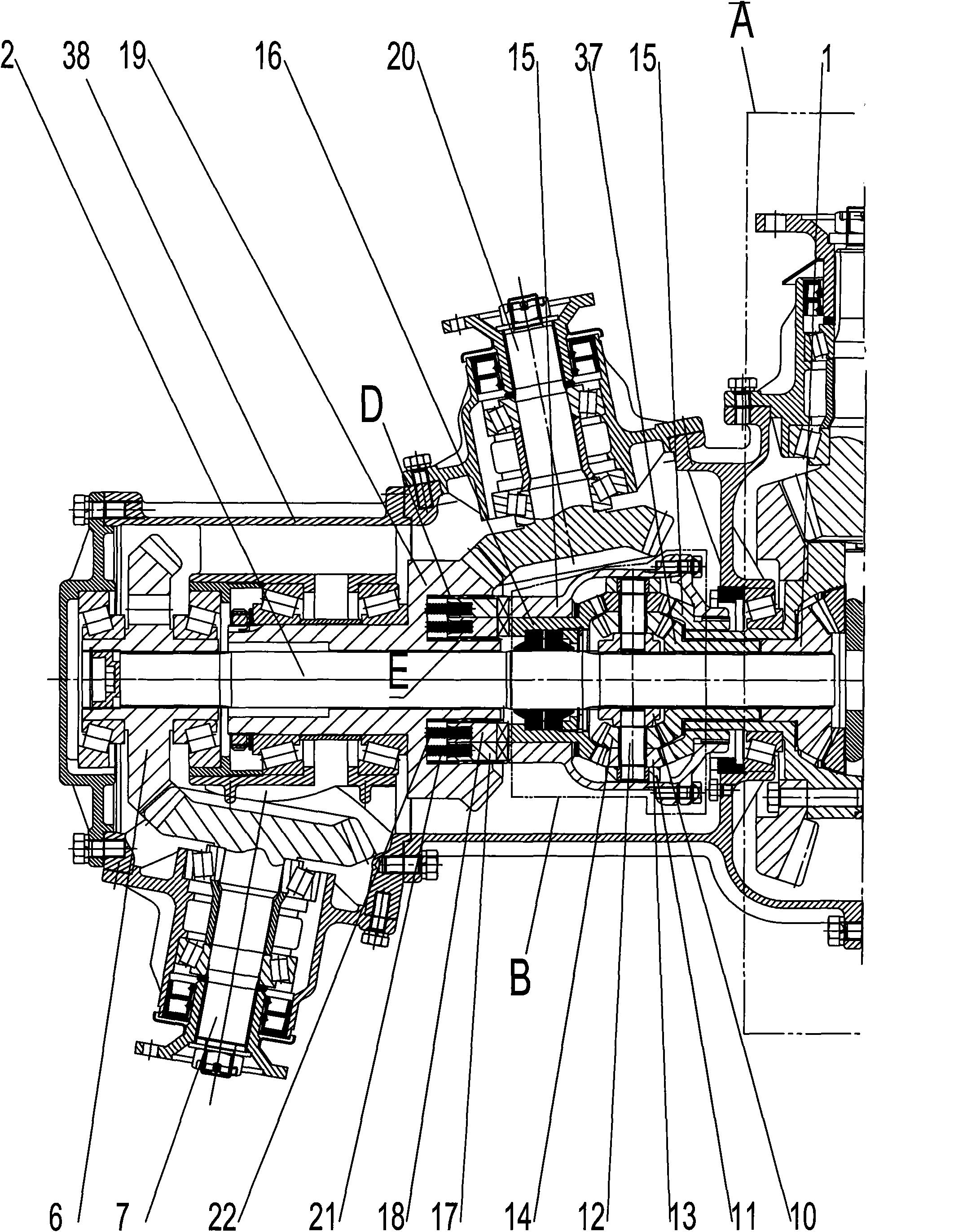

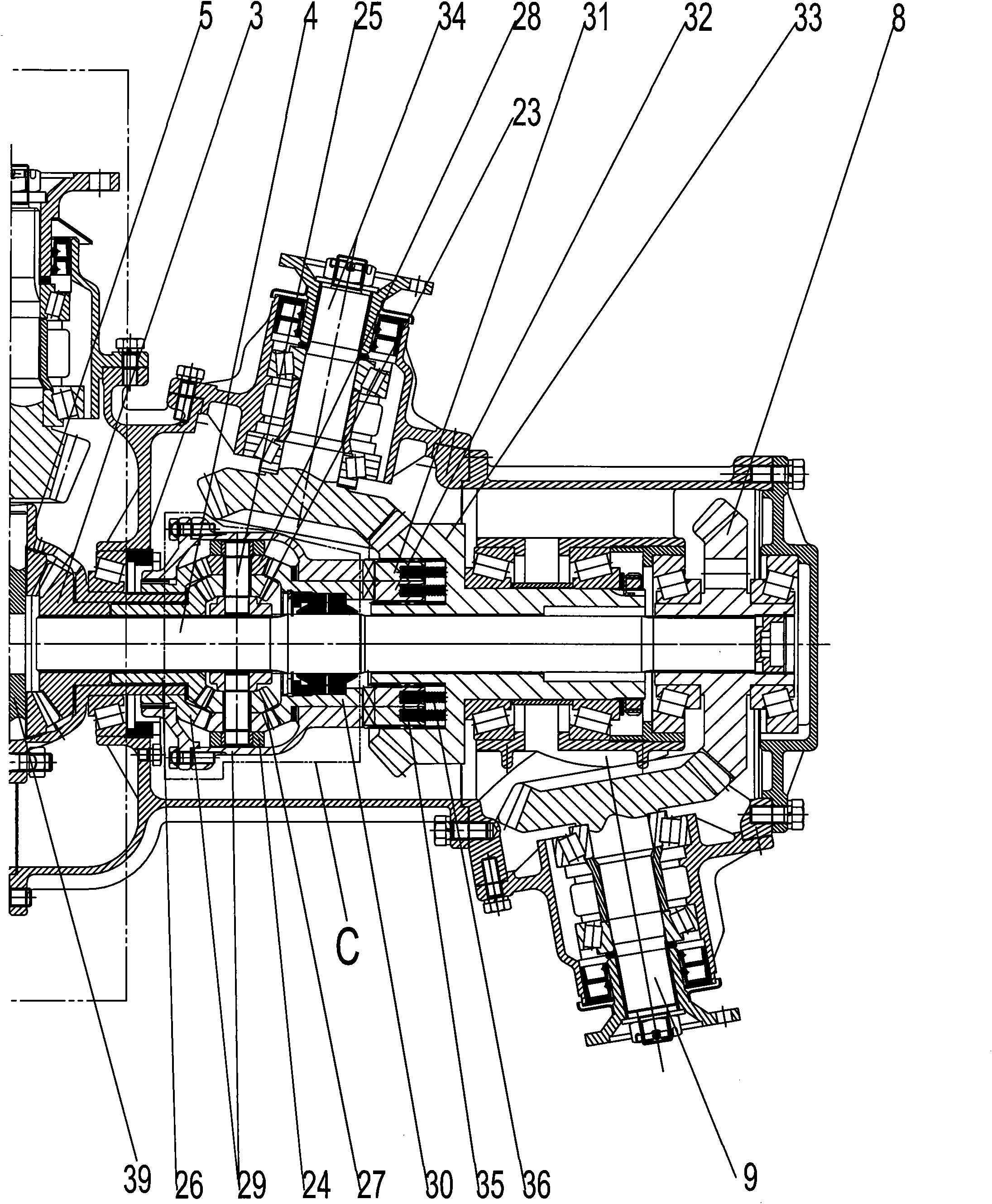

[0020] like figure 1 , 2 , As shown in 3, the anti-skid transmission includes housing 38, main deceleration symmetric conical planetary gear differential A, left half shaft 2, right half shaft 4, and main deceleration symmetric bevel planetary gear differential is located at housing 38 In the middle, the main deceleration symmetric bevel planetary gear differential is mainly composed of the main deceleration driving gear, the main deceleration driving gear, the differential case 5, the cross 39, the planetary gear, the left side shaft gear 1, and the right side shaft gear 3; The two ends of the gearbox housing 5 are supported in the housing 38 by bearings, and one end of the left half shaft 2 and the right half shaft 4 are splined with the left side shaft gear 1 and the right side shaft gear 3 respectively, and the left side shaft 2, The other end of the right half shaft 4 is supported in the housing 38 by bearings, and the other ends of the left half shaft 2 and the right ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com