Bubble micro valve and bubble micro valve-based micro-fluidic chip

A microfluidic chip and microvalve technology, which is applied in fluid controllers, valve devices, laboratory containers, etc., can solve the problems of unfavorable use by ordinary users, cumbersome operation, and complicated production technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Example 1. In a low-humidity environment and an open system, the opening method is external low-humidity air, and the bubble microvalve is opened during the sample addition process, and the generated bubbles block the liquid flow

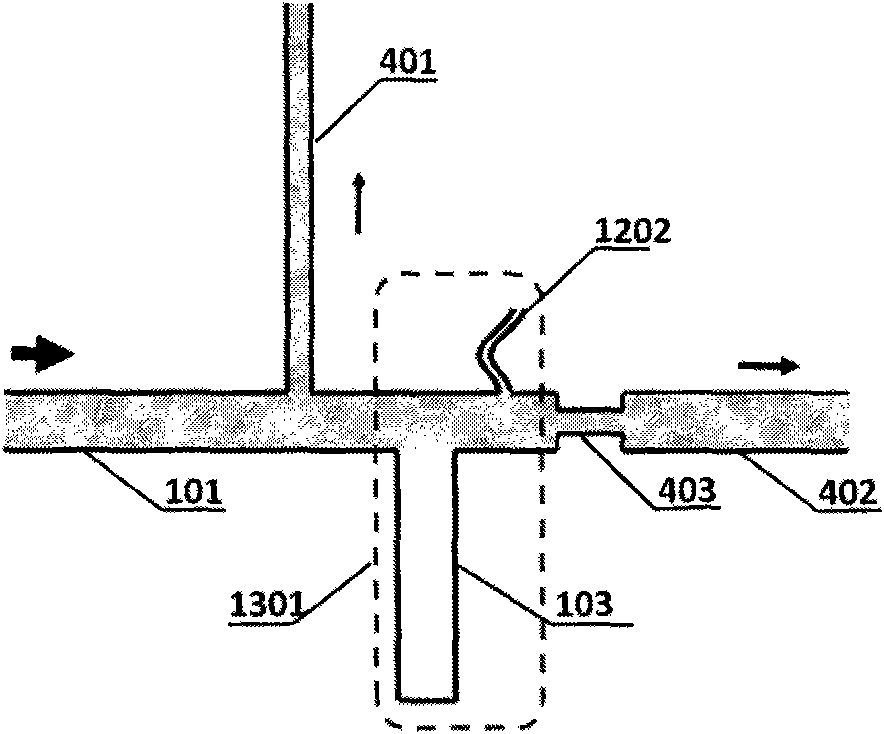

[0090] The chip of this embodiment comprises two layers, the upper layer is a PMMA cover sheet with a thickness of 1mm, and the lower layer is a PMMA bottom sheet with a thickness of 2mm. Such as Figure 4 and Figure 5 As shown, the structure of the upper surface of the bottom film includes a pipeline 101 , a narrow branch pipe 401 communicating with the pipeline 101 , and a wide branch pipe 402 communicating with the pipeline 101 through a barrier pipe 403 . The structure in this embodiment also includes the structure of the bubble microvalve 301 , and the gas pool 103 is directly communicated with the pipeline 101 . The width of pipeline 101 and wide branch pipe 402 is 0.5 mm, the width of narrow branch pipe 401 and blocking pipe 403 is ...

Embodiment 2

[0094] Example 2. In a low-humidity environment, in a closed system, the method of opening the bubble microvalve is a microfluidic chip with external low-humidity air

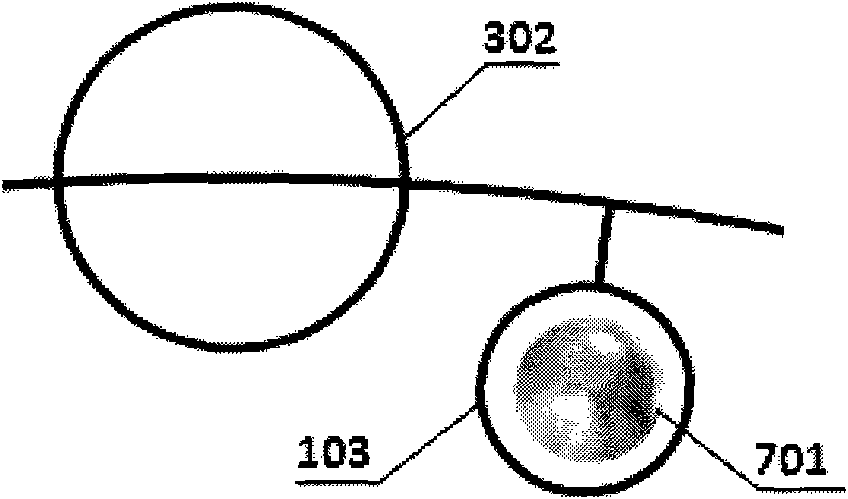

[0095] Such as Figure 6 As shown, the chip includes two layers, the upper layer is a PMMA cover sheet with a thickness of 1 mm, and the lower layer is a PMMA negative film with a thickness of 2 mm, and a microreactor array is arranged on the upper surface of the lower negative film. Microreactor arrays can be fabricated by existing techniques such as laser engraving, machining or thermocompression sealing. The microreactor array includes a pipeline 101 and 24 reaction pools 302 connected in series through the pipeline 101, and the distance between the reaction pools is equal. In this embodiment, the microreactor array is annular, that is, the pipeline 101 is annular and the reaction pools 302 are also arranged annularly.

[0096] Such as Figure 6 As shown, the microfluidic chip provided by the present inve...

Embodiment 3

[0099] Example 3. In a high-humidity environment, a closed system, and the microfluidic chip when the bubble microvalve is opened by internal low-humidity air

[0100] Such as Figure 7 As shown, the difference between the microfluidic chip of this embodiment and that of Embodiment 2 is that a color-changing silica gel bead 701 is added to the gas cell 103, and the rest of the devices are identical.

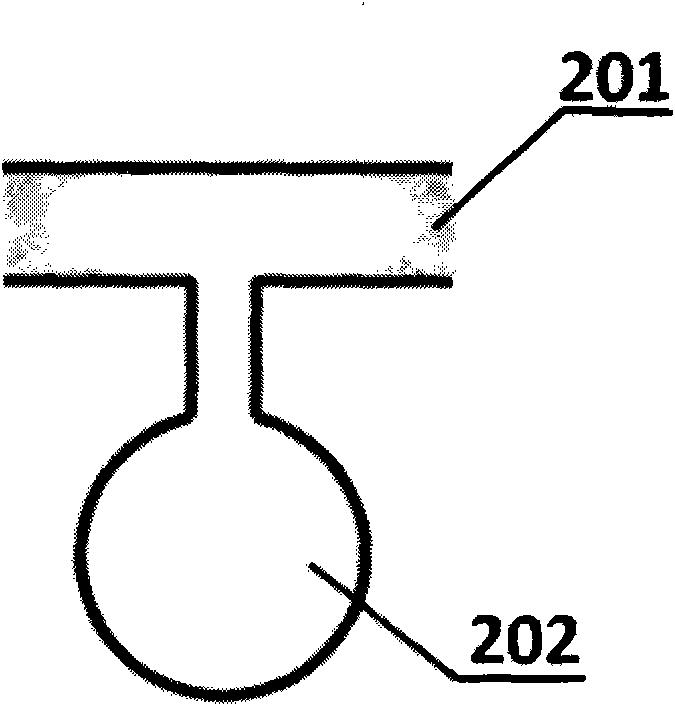

[0101] At a room temperature of 20° C. and a relative humidity of 75%, a color-changing silica gel bead 701 was added to the gas cell 103 , and then the inlet and outlet were closed for 1 hour. Afterwards, the sample inlet and the sample outlet were opened, and a syringe pump was used to add samples to the pipeline 101 at a flow rate of 60 μL / min, and the sample 201 was the PCR system solution. Samples enter each reaction pool in series, and then close the inlet and outlet again. After 3 minutes, if figure 2 As shown, the gas 202 increases in volume and enters the pipeline, fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com