Professional lamp shock absorber

A technology for shock absorbers and lamps, applied in the field of vibration reduction, can solve the problems of inability to meet the vibration reduction requirements of suspended lamps and single vibration reduction means, and achieve the effects of enhancing service life, saving maintenance costs, and improving comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

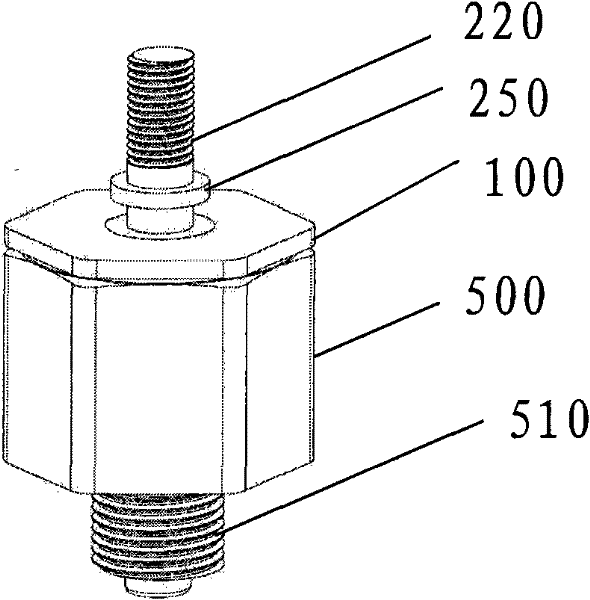

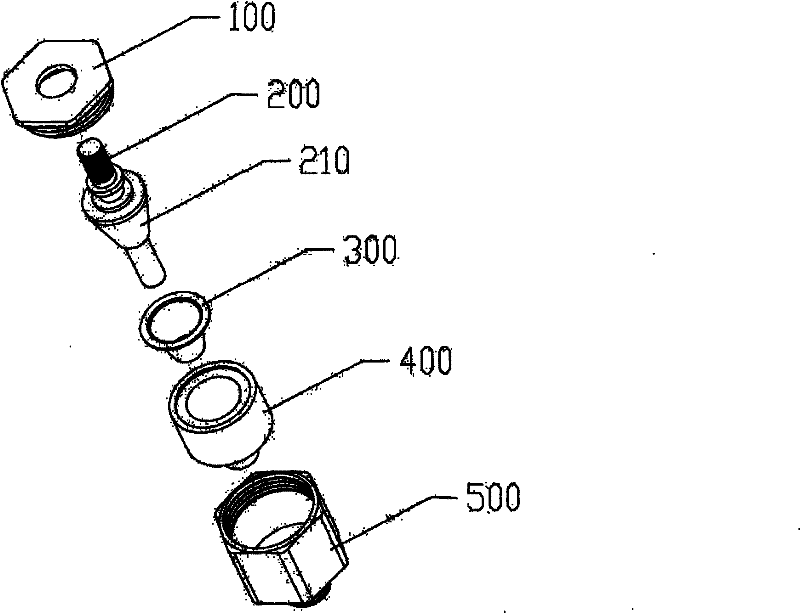

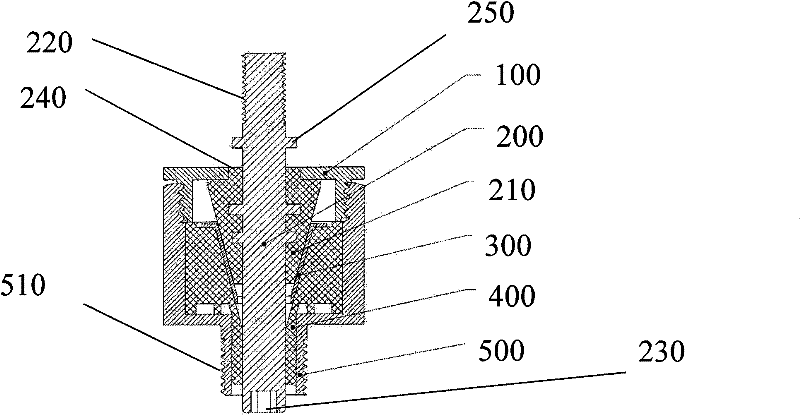

[0019] Such as figure 1 , figure 2 and image 3 As shown, in the embodiment of the shock absorber for professional lamps provided according to the present invention, it includes a shock absorber screw cap 100, a special-shaped screw 200, a rubber sleeve 210 as the first buffer device, a friction inner sleeve 300, and a second buffer The rubber lining 400 and the shock absorber shell 500 of the device, wherein the special-shaped screw rod 200 and the rubber sleeve 210 are integrally formed by molding. The concavo-convex structure between the rubber sleeve 210 and the special-shaped screw 200 is connected like image 3 , There are several layers of bosses on the special-shaped screw 200, and the opposite rubber sleeve 210 is opposite to the groove because of these bosses, so that a reliable connection between the two can be ensured. The special-shaped screw 200 is provided with a lamp mounting thread 220 for connecting a lamp. In order to limit the position when installing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com