Feeding mechanism for vacuum casting furnace

A melting and casting furnace, vacuum technology, applied in the field of improvement of the feeding mechanism of the vacuum melting and casting furnace, can solve the problems of difficult overlapping of material rods, molten steel splashing and burning the smelting chamber, material rod vibration and other problems, so as to improve accuracy and stability, avoid Major equipment accidents, the effect of avoiding swaying and shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

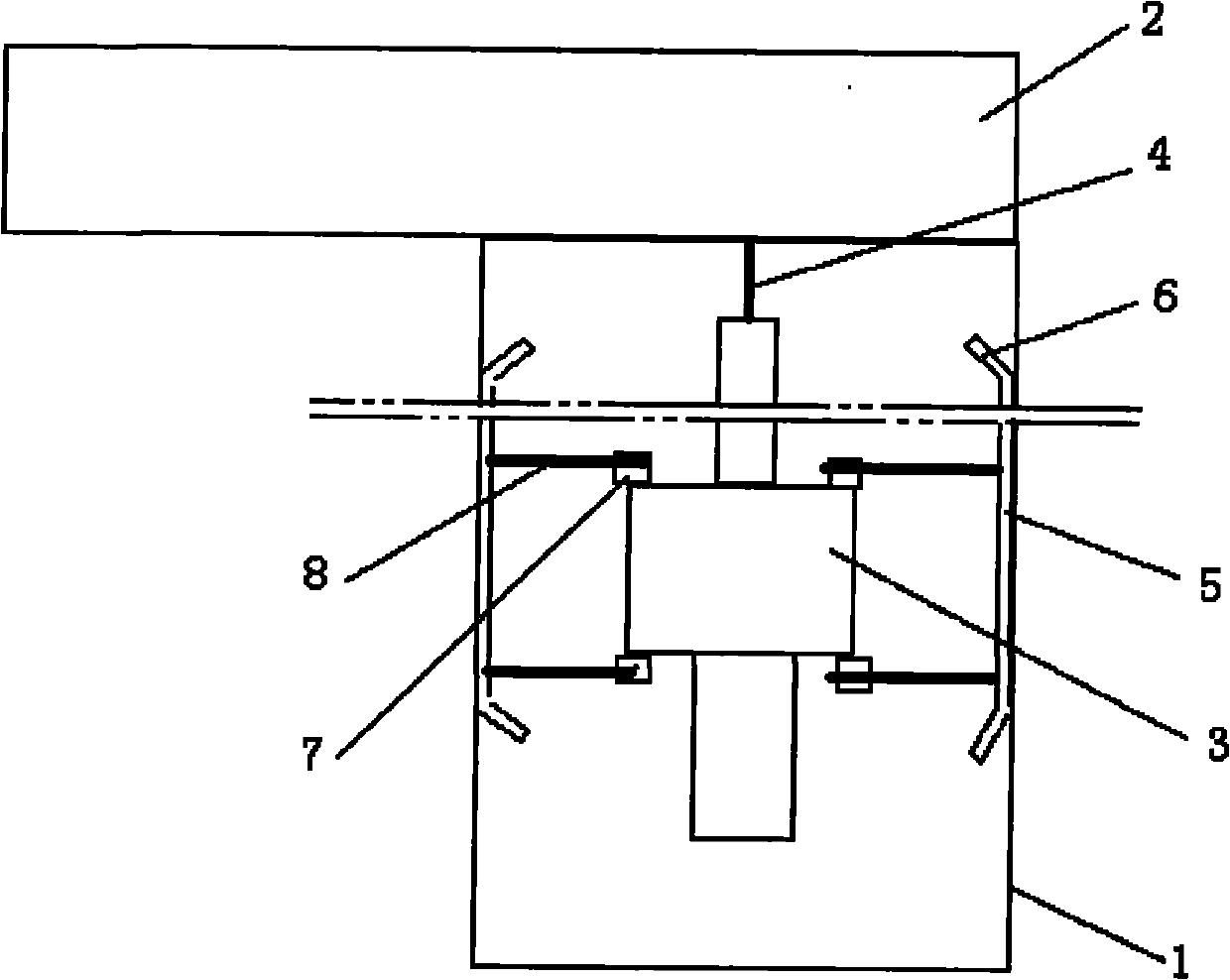

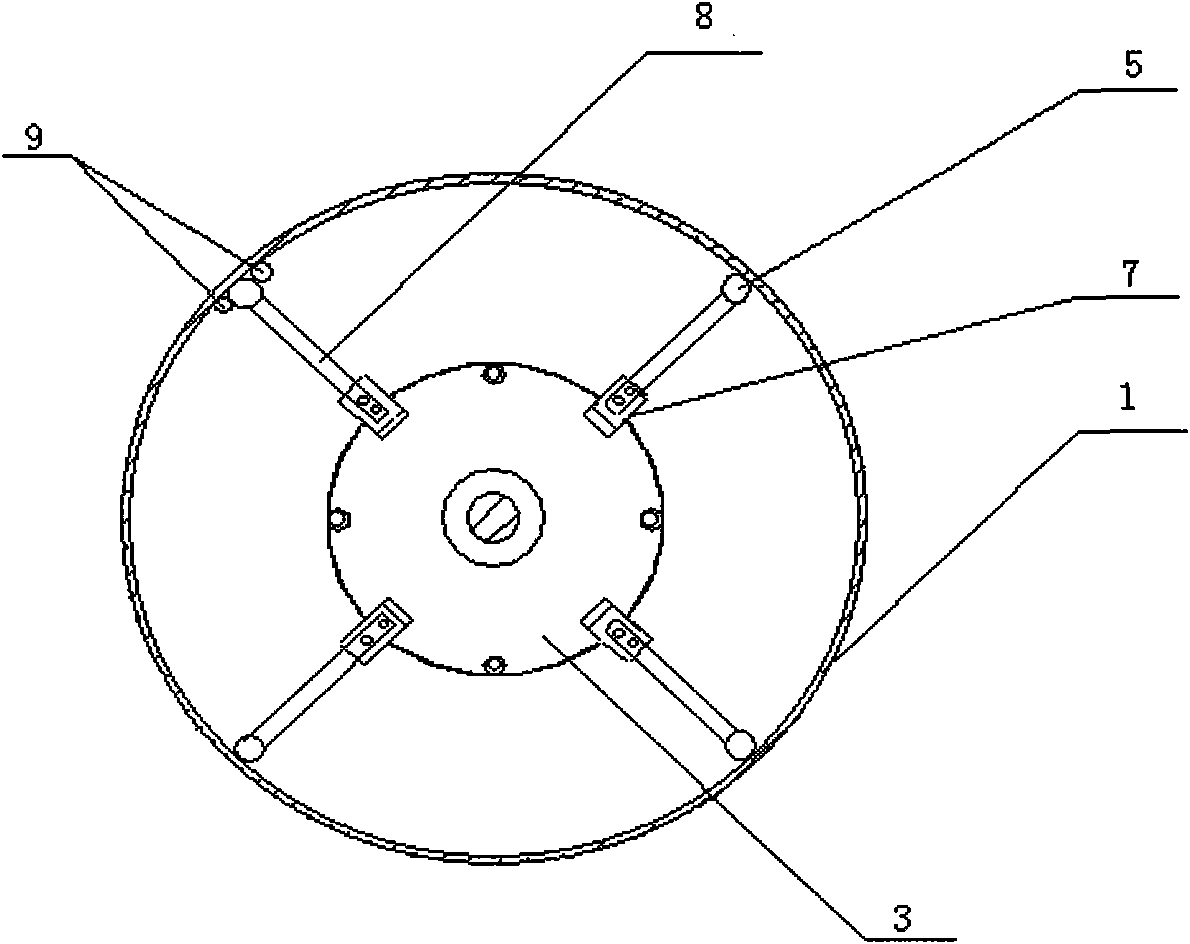

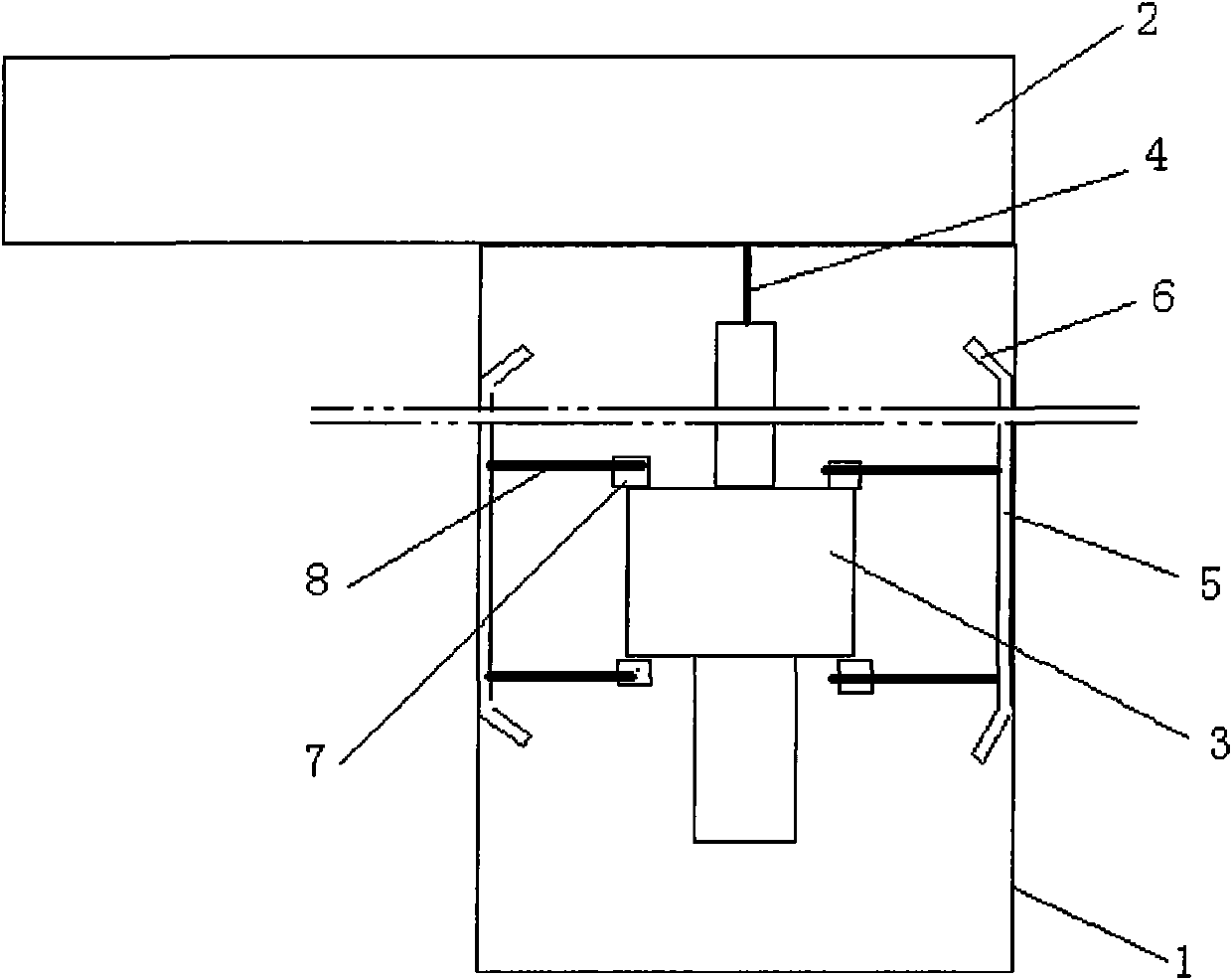

[0008] The present invention will be described in further detail below. see figure 1 , 2 , a vacuum casting furnace feeding device, including a feeding chamber 1 and a driving mechanism 2, the upper end of the circular section shell of the feeding chamber 1 and the right end of the shell of the driving mechanism 2 are connected as a whole through a connecting flange. There is a grabbing mechanism 3 inside the feeding chamber 1, and the grabbing mechanism 3 is composed of an upper connecting rod, a middle cylinder and a lower claw. The upper end of the connecting rod is connected with the lifting mechanism in the driving mechanism 2 by a wire rope or a chain.

[0009] It is characterized in that there are 3 or 4 guiding mechanisms uniformly distributed along the circumference around the grasping mechanism 3 , and each guiding mechanism is composed of a guiding rod 5 , two connecting pieces 7 and two fixing rods 8 . The guide rod 5 is a circular tube or a round rod, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com