Waterproof machine shell for water controller

A technology for water controllers and casings, which is applied in the field of waterproof casings for water controllers. It can solve the problems of poor overall heat dissipation, large amount of glue used, and easy to burn circuits, etc., and achieves extended service life, reliable steam protection, and reliable work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

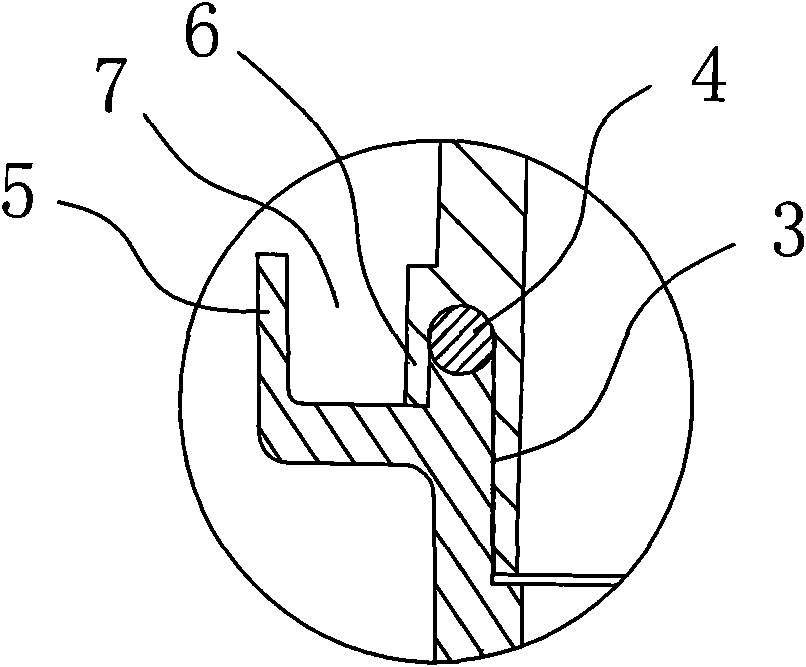

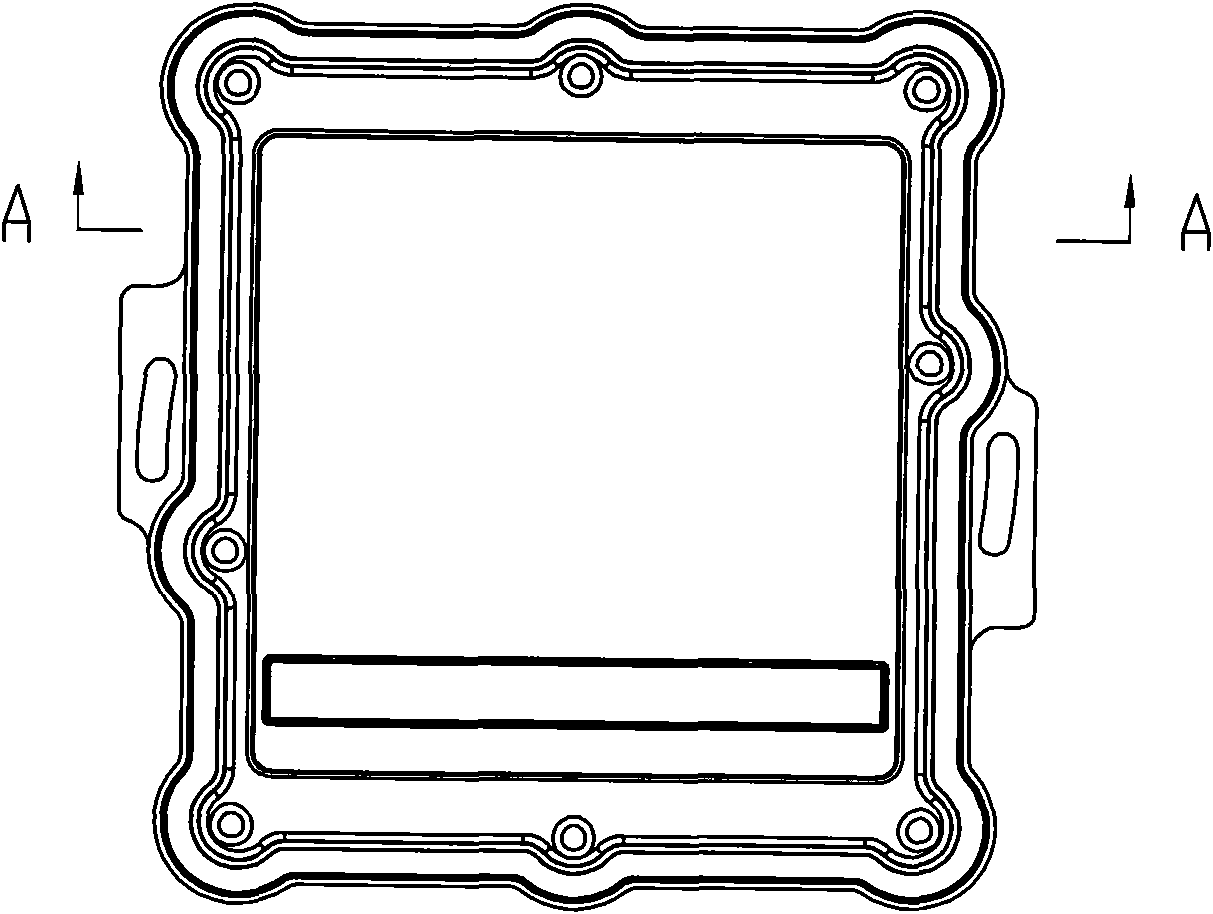

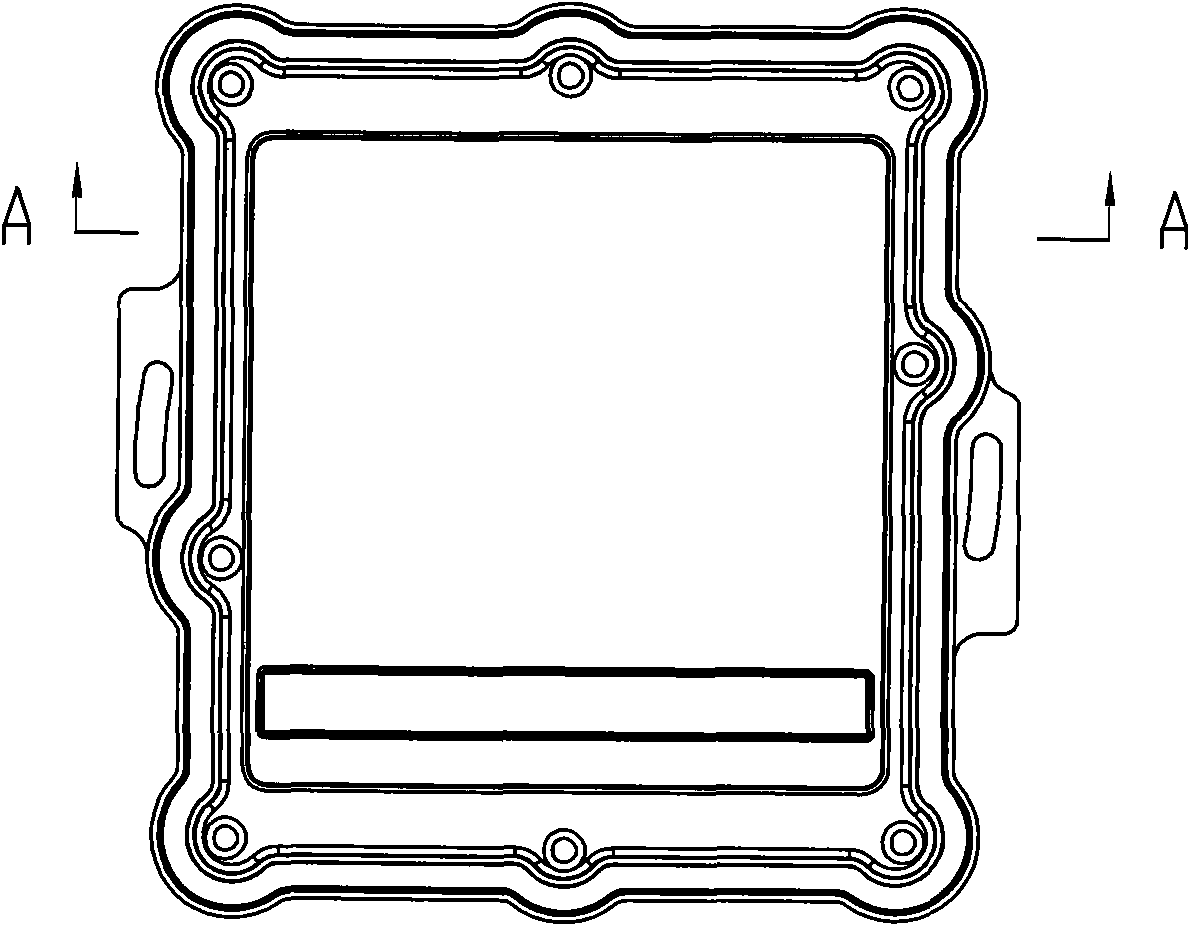

[0010] Such as Figure 1 to Figure 3 As shown, the waterproof casing of the water controller of the present invention includes an upper casing 1 and a lower casing 2 that are sealed and fastened to each other. A male stop is provided on the inner wall of the lower port of the upper casing 1, and a male stop is provided on the inner wall of the lower port of the lower casing 2. The inner wall of the upper port of the upper port is provided with a female seam tightly matched with the male seam, and the mating surface 3 of the female seam and the male seam is coated with waterproof oil; the lower port of the upper shell 1 and the lower shell The upper port of 2 is respectively provided with a groove for inserting a sealing ring 4 on the outer periphery adjacent to the male and female seams; on the outer periphery of the groove at the upper port of the lower shell 2, an upward flanging 5 is provided. The flange 5 and the outer wall 6 of the lower port of the upper shell 1 form a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com