Ultrasonic wave generating device for controlling solidification structure

A generation device and a technology to control solidification, applied in the field of ultrasonic generation devices, can solve problems such as difficult direct transmission of ultrasonic waves, achieve high economic benefits and improve transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, the descriptions presented here are preferred examples for the purpose of illustration only and are not intended to limit the present invention, so other equivalents and modifications may be made otherwise without departing from the scope of the present invention. In the drawings, components considered to have the same configuration and function have substantially the same reference numerals.

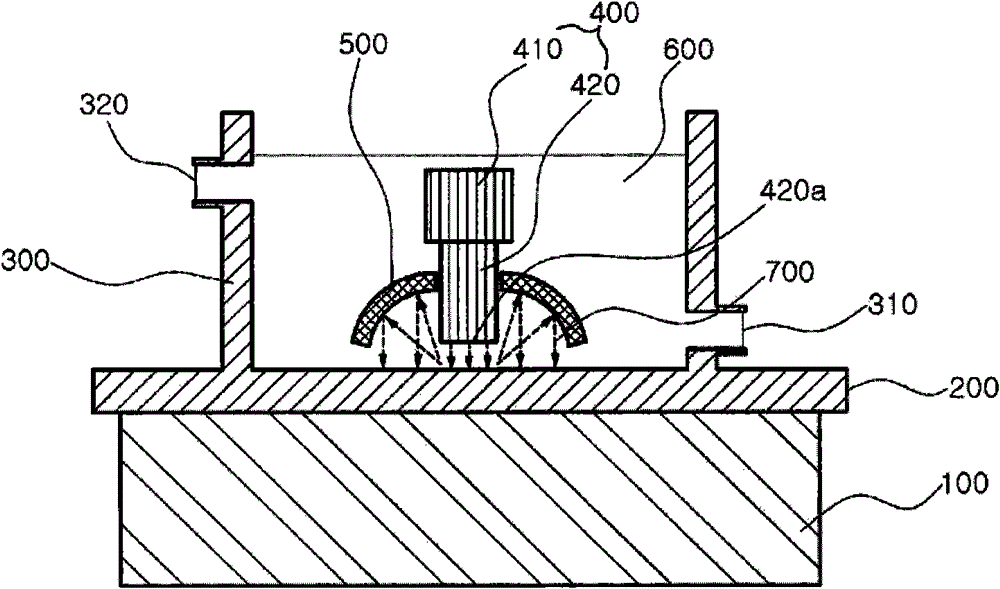

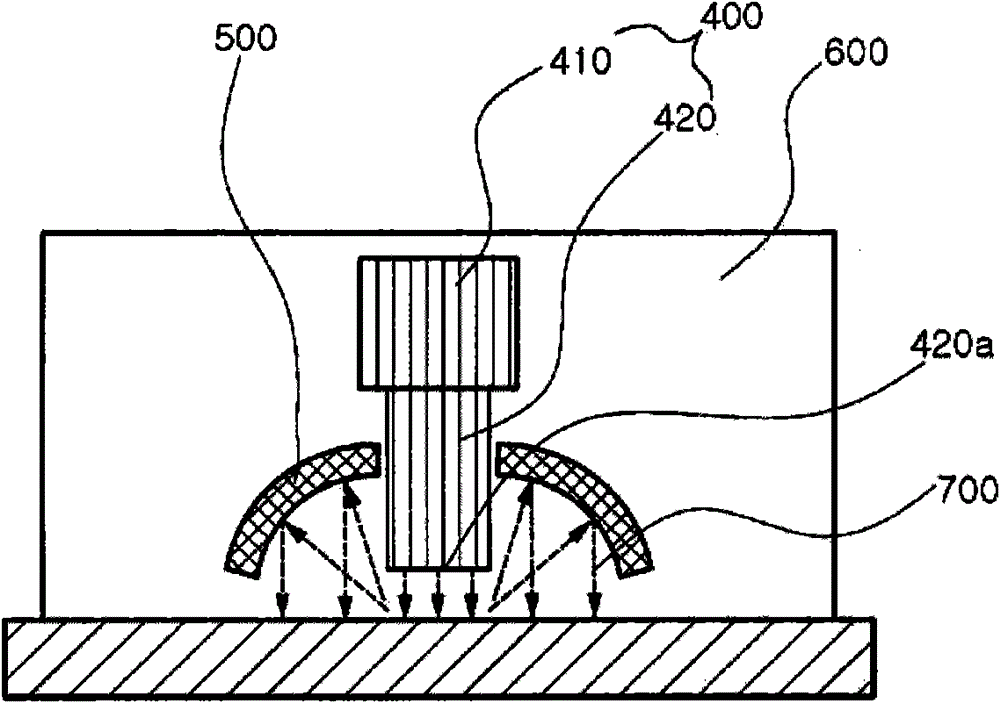

[0028] figure 1 is a block diagram showing an ultrasonic generating device for controlling coagulated tissue according to an exemplary embodiment of the present invention. refer to figure 1 , the casting 200 is filled with the molten metal 100 during solidification, and the ultrasonic transducer 400 for generating ultrasonic waves and applying the generated ultrasonic waves to the inside of the casting 200 is arranged outside the casting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com