Yellow phosphor powder and preparation method thereof

A technology of yellow phosphor powder and flux, applied in the field of yellow phosphor powder and its preparation, can solve the problems of aging luminous intensity, luminous efficiency and color purity decline and decrease, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

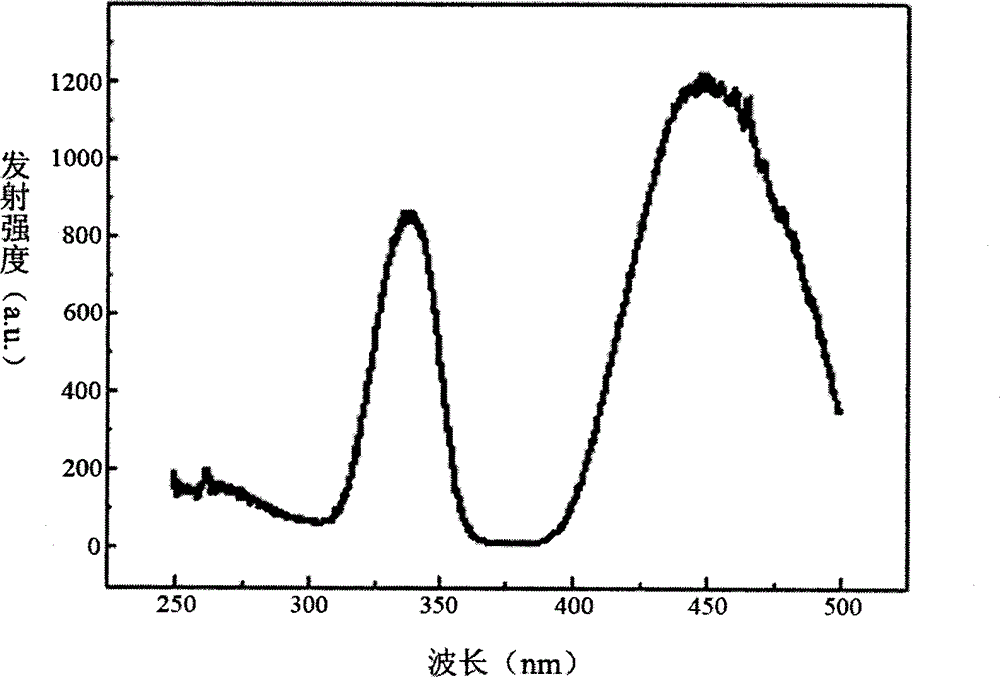

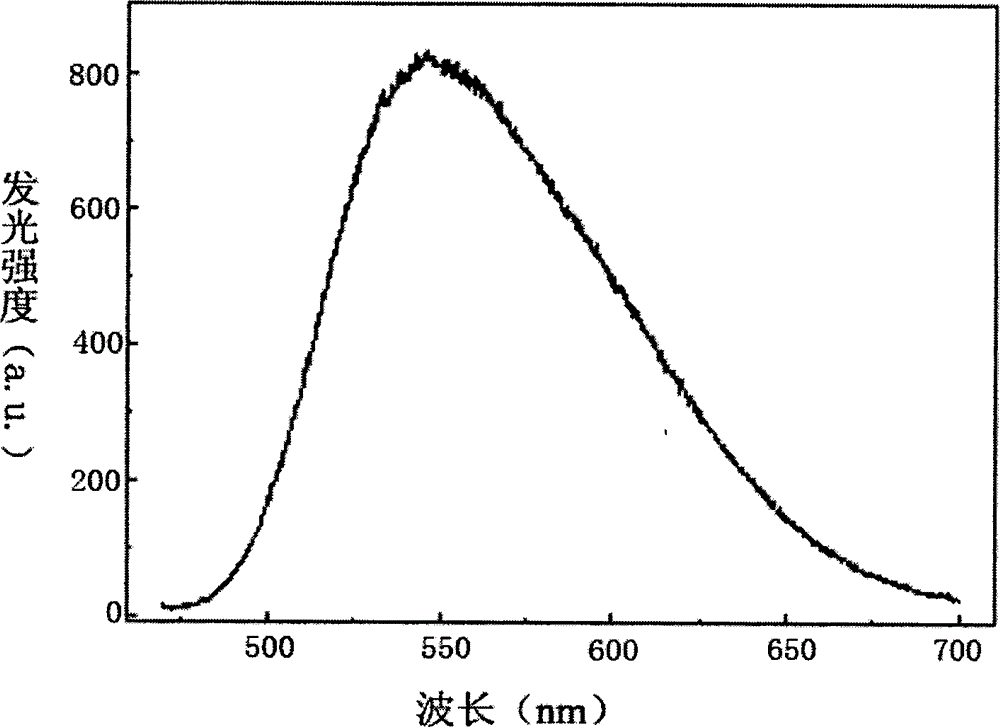

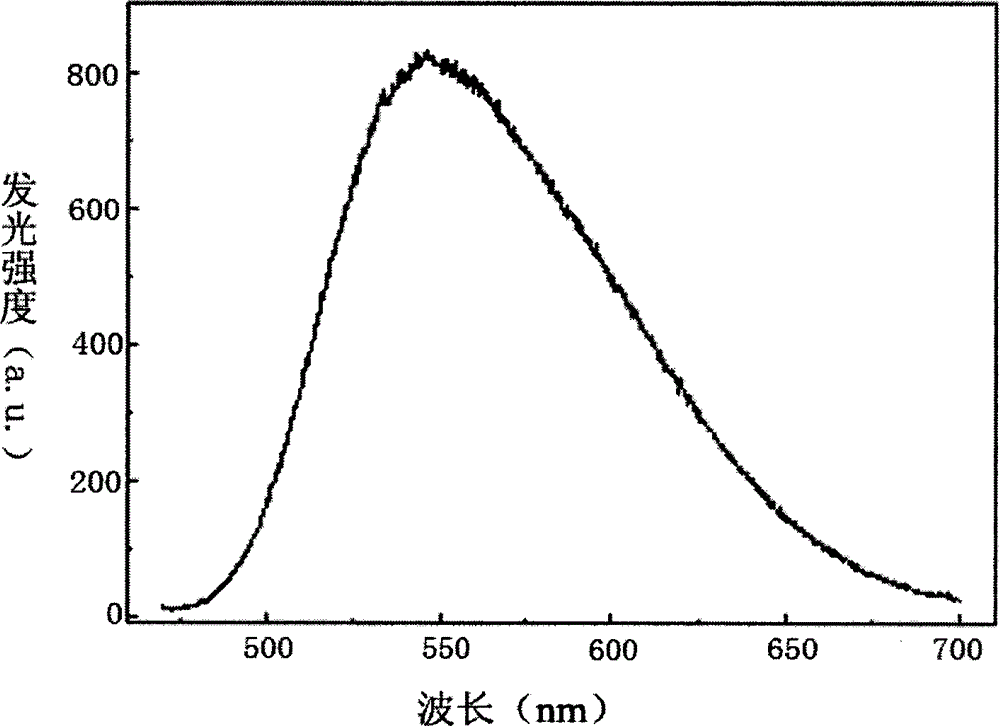

Image

Examples

Embodiment 1

[0028] To prepare with general formula Y 3-x-y-z Gd z Sb y Al 5 o 12 : Ce x The yellow fluorescent powder 10g shown is an example, where x is the number of moles of cerium atoms, y is the number of moles of antimony atoms, x is 0.05, y is 0.02, and z is 1.0. The raw materials used and their preparation methods are as follows:

[0029] 1. Raw material pretreatment

[0030] Pre-fire yttrium oxide, antimony oxide, gadolinium oxide and cerium oxide in a high-temperature furnace at 800°C for 2 hours to remove moisture and impurities.

[0031] 2. Ingredients

[0032] According to formula Y 1.93 Gd 1.0 Sb 0.02 Al 5 o 12 : Ce 0.05 Weigh 3.2759g yttrium oxide, 0.0438g antimony oxide, 5.8634g aluminum hydroxide, 0.1294g cerium oxide, 2.7248g gadolinium oxide, and then weigh 0.5g boric acid as a flux, grind in a mortar for 20 minutes, and prepare the raw material mixture.

[0033] 3. Sintering

[0034] The raw material mixture was put into a corundum crucible, placed in a ...

Embodiment 2

[0040] To prepare with general formula Y 3-x-y-z Gd z Sb y Al 5 o 12 : Ce x The yellow fluorescent powder 10g shown is an example, where x is the number of moles of cerium atoms, y is the number of moles of antimony atoms, z is the number of moles of gadolinium atoms, x is 0.05, y is 0.02, and z is 1.0. The raw materials used Its preparation method is as follows:

[0041] In batching step 2, according to the general formula Y 1.93 Gd 1.0 Sb 0.02 Al 5 o 12 : Ce 0.05 Weigh yttrium oxide, gadolinium oxide, antimony oxide, aluminum hydroxide, and cerium oxide in the same amount as in Example 1, and the flux is 0.1 g of boric acid. Other steps in this step are the same as in Example 1 to prepare a raw material mixture. Other steps are the same as in Example 1 to prepare yellow fluorescent powder.

Embodiment 3

[0043] To prepare with general formula Y 3-x-y-z Gd z Sb y Al 5 o 12 : Ce x The yellow fluorescent powder 10g shown is an example, where x is the number of moles of cerium atoms, y is the number of moles of antimony atoms, z is the number of moles of gadolinium atoms, x is 0.05, y is 0.02, and z is 1.0. The raw materials used Its preparation method is as follows:

[0044] In batching step 2, according to the general formula Y 1.93 Gd 1.0 Sb 0.02 Al 5 o 12 : Ce 0.05Weigh yttrium oxide, gadolinium oxide, antimony oxide, aluminum hydroxide, and cerium oxide in the same amount as in Example 1, and the flux is 0.7 g of boric acid. Other steps in this step are the same as in Example 1 to prepare a raw material mixture. Other steps are the same as in Example 1 to prepare yellow fluorescent powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com