Loom transmission mechanism

A technology of transmission mechanism and driving mechanism, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problem of tooth slippage, unable to find weft breakage, etc., and achieve the effects of convenient operation, simple and reasonable structure, and accurate control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

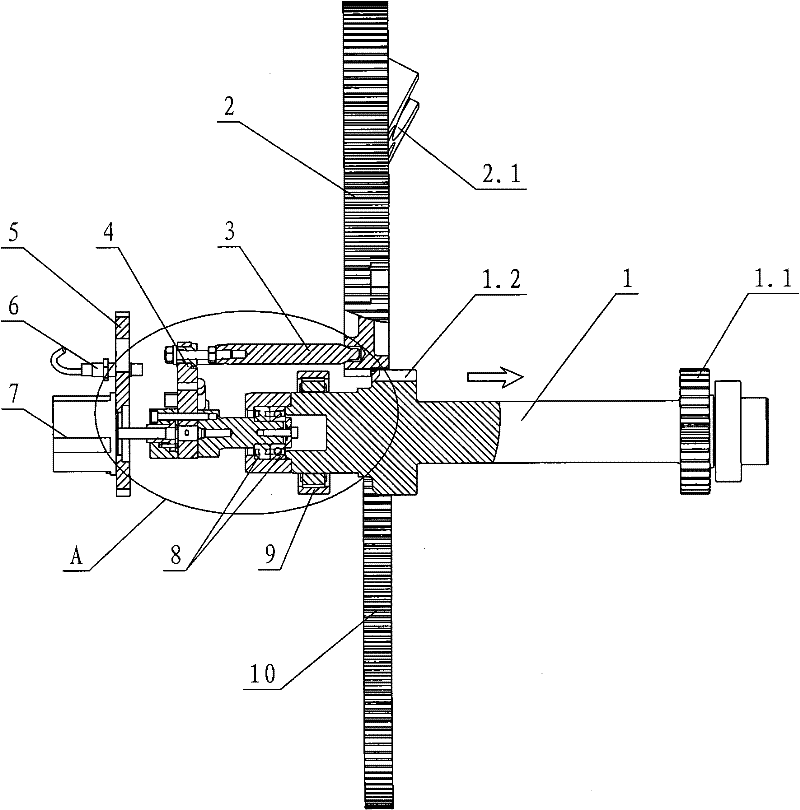

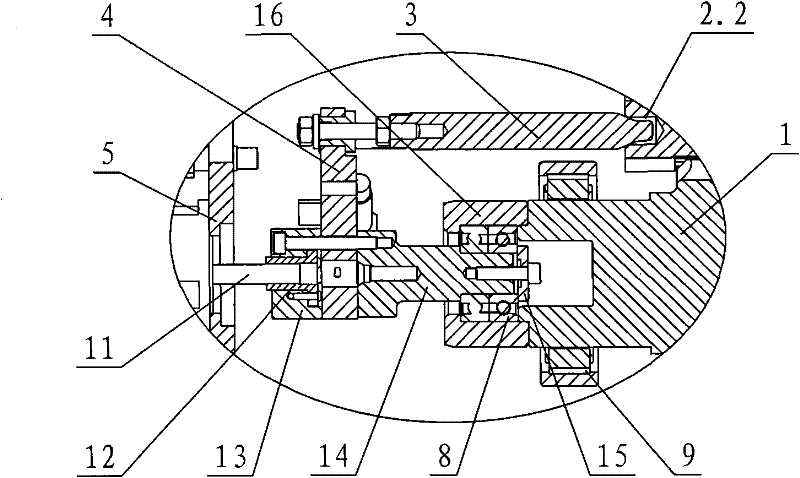

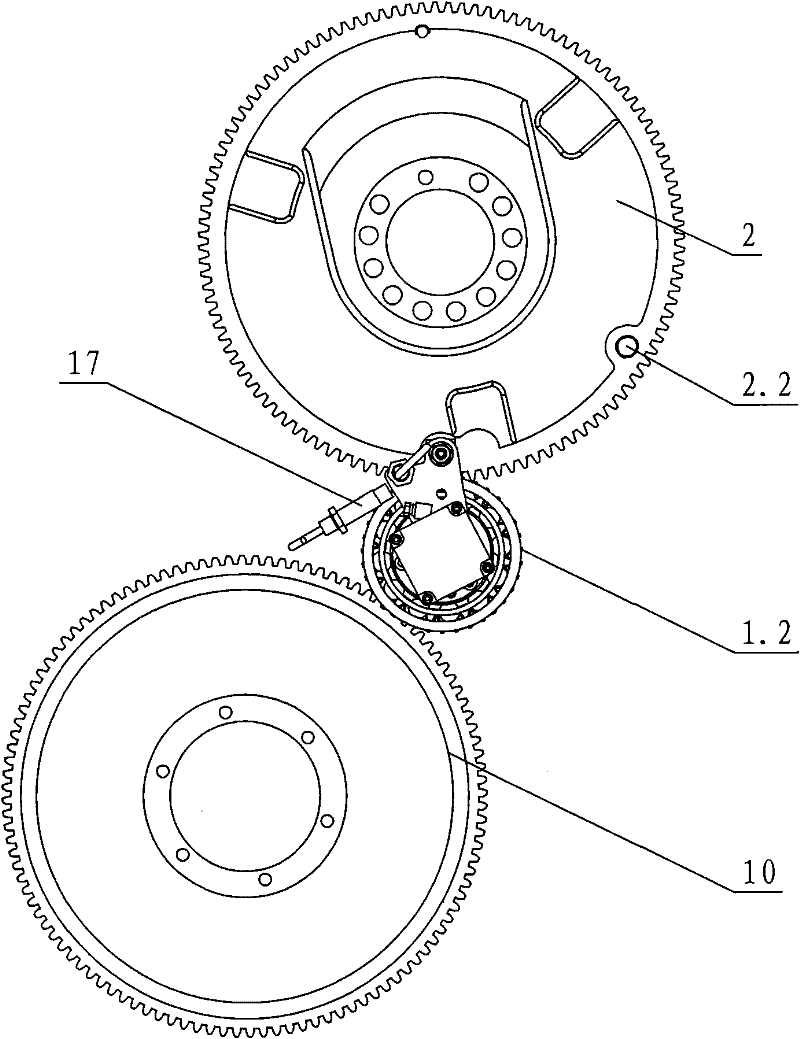

[0026] see Figure 1-Figure 4 , the transmission mechanism of the loom includes a main shaft driven by a drive motor, a transmission shaft of a beating mechanism connected to the main shaft, an input shaft of an opening mechanism, a driving mechanism for controlling the axial movement of the main shaft, and a stopper for stopping the transmission shaft of the beating mechanism. The driving device, the main shaft is axially slidably arranged in the casing, and the output shaft of the drive motor, the beating-up mechanism transmission shaft and the shedding mechanism input shaft are respectively provided with a driving gear, a beating-up driving gear 2 and a shedding driving gear 10. The main shaft is a double gear shaft 1 with a first gear 1.1 and a second gear 1.2 respectively arranged at the front and rear ends; the first gear meshes with the drive gear, and the second gear meshes with the beating-up drive gear and the opening drive gear.

[0027] The driving mechanism is a m...

no. 2 example

[0032] see Figure 5-Figure 8 , the transmission mechanism of the loom comprises a main shaft driven by a drive motor 26, a beating mechanism transmission shaft 25 and an opening mechanism input shaft 23 respectively connected to the main shaft transmission, a driving mechanism for controlling the axial movement of the main shaft, and a beating mechanism transmission shaft The stopping device for stopping, the main shaft is axially slidably arranged in the box, and the output shaft of the drive motor, the transmission shaft of the beating mechanism and the input shaft of the shedding mechanism are respectively provided with a driving gear 22, a beating driving gear 2 and a shedding driving gear 10. The main shaft is a double gear shaft 1 with a first gear 1.1 and a second gear 1.2 respectively arranged at the front and rear ends; the first gear meshes with the drive gear, and the second gear meshes with the beating-up drive gear and the opening drive gear.

[0033] The drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com