Water stop rubber protection device for flat steel gate

A water-stop rubber and protective device technology, which is applied in coastline protection, water conservancy engineering, sea area engineering, etc., can solve the problems of water-stop rubber without protection device, aggravate the opening and closing force, and poor sealing, so as to save the filling time of hydraulic pressure , improve work efficiency, reduce the effect of opening and closing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

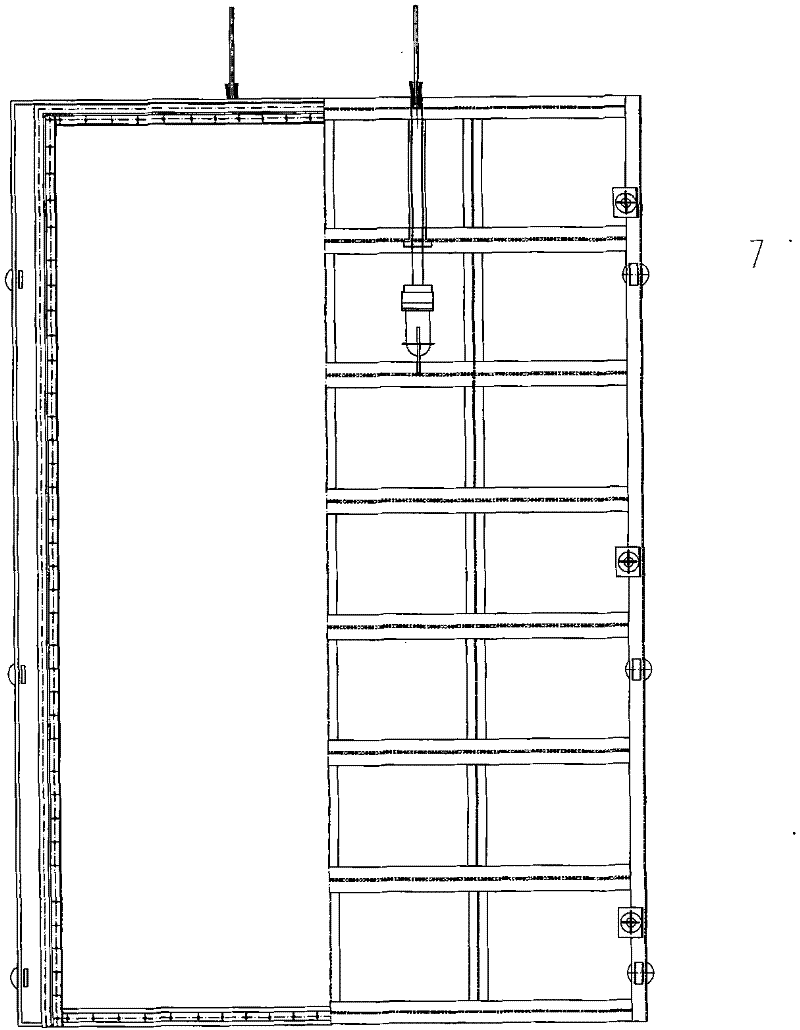

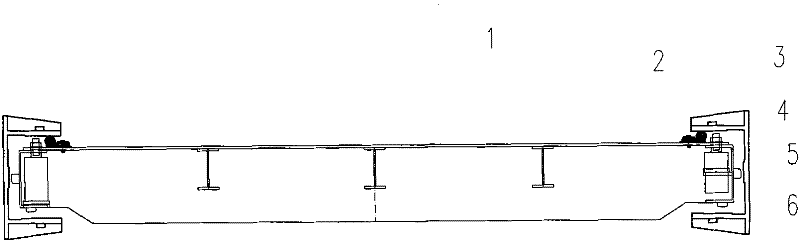

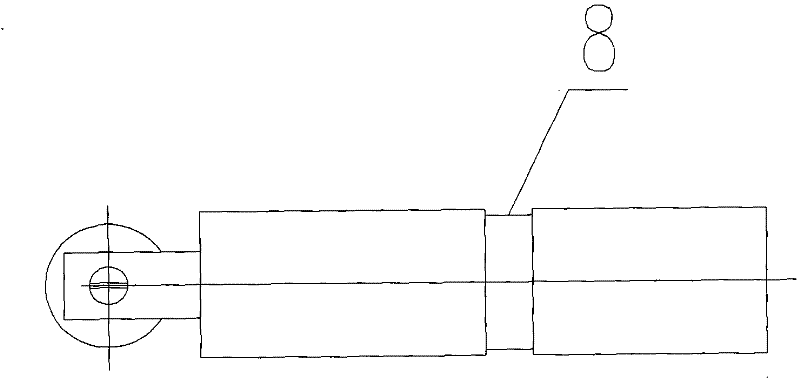

[0019] like Figure 1 ~ Figure 4 Shown: including door body 1, water stop rubber 2, guide groove 3, hydraulic cylinder 4 guide wheel 5, hydraulic cylinder flange 6, water filling balance valve 7, card slot 8 and segmented flange 9.

[0020] In the present invention, a water-filling balance valve 7 is installed on the door body 1, the water-stop rubber 2 is arranged on the door body 1, the hydraulic cylinder flange 6 is welded on the frame of the door body 1, and the frame of the door body 1 passes through the hydraulic cylinder The flange 6 is installed with a fixed hydraulic cylinder 4, and the guide wheel 5 is installed at the piston rod end of the hydraulic cylinder 4. A rectangular hole is opened on the frame of the door body 1, and the size of the hole can be inserted into the piston rod of the hydraulic cylinder 4 and the guide wheel 5. Hole is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com