Push-type displacement feedback pneumatic deviation correction mechanism of vibrating platform used under centrifugal environment

A displacement feedback, vibration table technology, applied in vibration testing, machine/structural component testing, measurement devices, etc., can solve the problem that the vibration table cannot be directly applied to the centrifugal environment, and achieves low axial stiffness, simple control, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

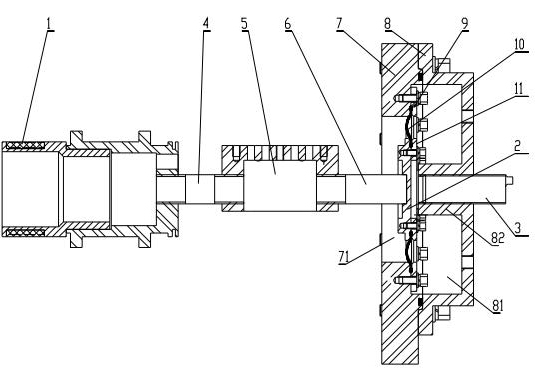

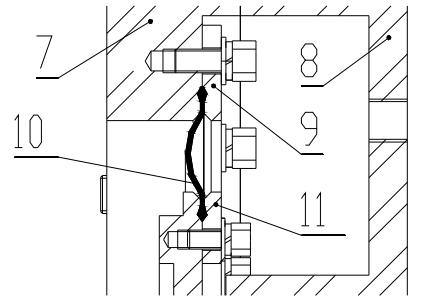

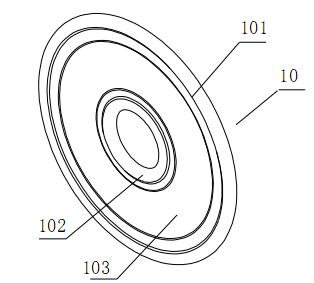

[0028] With reference to accompanying drawing, further illustrate the present invention:

[0029] The push-type displacement feedback air pressure correction mechanism for a vibration table in a centrifugal environment includes a platform push rod 4 and a deviation correction push rod 6 symmetrically arranged at both ends of the vibration platform 5, and the platform push rod 4 and a driving vibration platform The reciprocating vibration vibration table moving part 1 linkage;

[0030] The deviation correction push rod 6 is linked with a deviation correction mechanism;

[0031] The deviation correction mechanism includes: a partition 2 affixed to the correction push rod 6, a closed hyperbaric chamber 8 located on both sides of the partition 2, and a low pressure chamber 7 connected to the atmosphere. The displacement sensor 3 of the cabin 8 and facing the partition plate 2 to monitor the displacement of the deviation correction push rod 6; the output signal of the displacement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com