Grout sleeve with function of coordination deformation with concrete for prefabricated components

A technology of prefabricated components and grouting sleeves, applied to building components, structural elements, building reinforcements, etc., can solve problems such as structural damage, large cracks in concrete components, hindering the coordinated deformation of concrete and steel bars, etc., and reduce the shear capacity , the effect of reducing the axial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

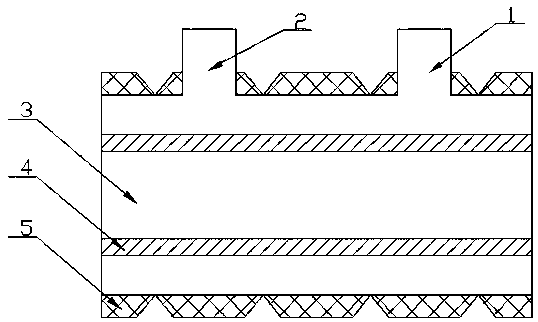

[0025] Such as figure 1 As shown, a grouting sleeve for prefabricated components that coordinates with the deformation of concrete includes a sleeve body 3, the sleeve body 3 is provided with a grouting port 1 and a grout outlet 2, and the sleeve body 3 Convex grooves 5 and reinforcing ribs 4 are provided on the side walls.

[0026] Made of ductile iron material, the total length of the sleeve body 3 is 240mm, which is used to connect steel bars with a diameter of 12mm. The sleeve body 3 is in the shape of a barrel with an inner diameter of 26mm. The thickness is 1mm, and the protruding part surrounds the sleeve vertically, each section is 10mm wide along the axis, and the groove is 2mm wide along the axis. In order to avoid affecting the strength of the sleeve due to stress concentration, arc smoothing can be used near the junction of the concave and convex parts. In order to maintain the connection ability of the sleeve to the two parts of the steel bars, no groove is prov...

Embodiment 2

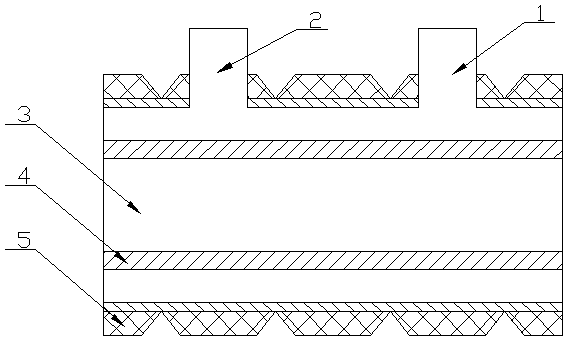

[0029] Such as figure 2 As shown, two kinds of materials are used, the grouting sleeve with a total length of 240mm is used to connect steel bars with a diameter of 12mm, and the sleeve body 3 is a PVC drum with an inner diameter of 26mm and a thickness of 2mm. The convex groove 5 is a PVC cylinder surrounded by multi-segment end steel vertical perimeter lines, the steel wall thickness is 5mm, each section is 10mm wide along the axis, and a gap of 2mm width is left between each section of steel.

[0030] In this embodiment, vertical reinforcing ribs 4 are provided. The reinforcing ribs 4 have a width of 5 mm and a thickness of 4 mm, and are evenly distributed along the outside of the sleeve. The rib material can be metal or carbon fiber. The reinforcement ribs can be evenly distributed along the circumference of the sleeve, or can be distributed non-uniformly around the sleeve, so as to meet the different requirements for the tension of the sleeve.

Embodiment 3

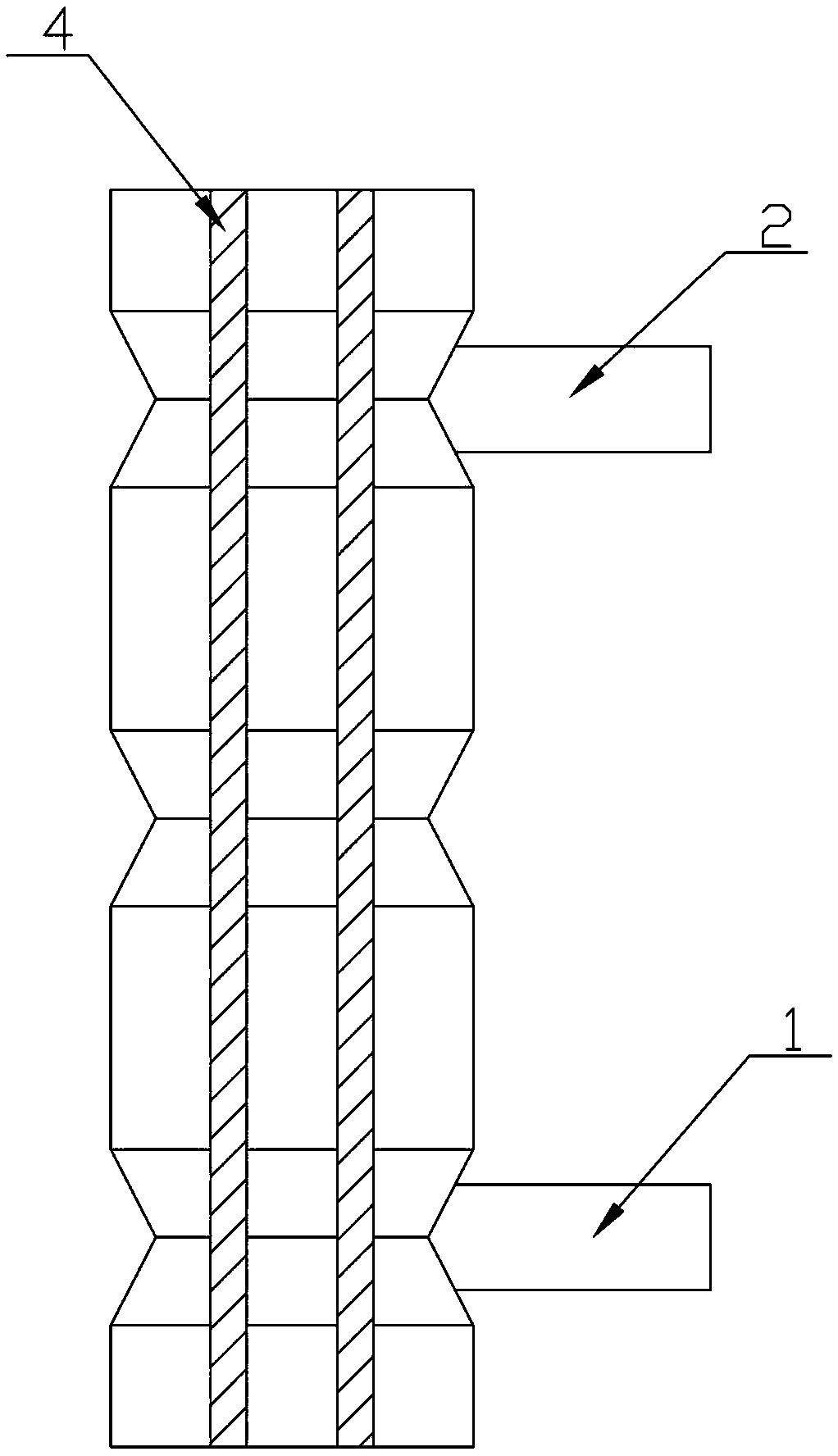

[0032] Such as image 3 As shown, the grouting sleeve is made of ductile iron material and has a total length of 320mm, which is used to connect steel bars with a diameter of 16mm. The inner side of the sleeve is in the shape of a barrel with a diameter of 30mm. The wall thickness of the inlet part is 1mm, and the protruding part surrounds the sleeve perpendicular to the circumference of the sleeve. Each section is 10mm wide along the axis, and the groove is 2mm wide along the axis. In order to avoid affecting the strength of the sleeve due to stress concentration, arc smoothing can be used near the junction of the concave and convex parts.

[0033] In order to increase the vertical stiffness of the sleeve, a vertical rib 4 is added in this case. The reinforcing ribs 4 have a width of 5mm and a height of 4mm, and are evenly distributed along the outside of the sleeve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com