Anti-shear peg

A shear-resistant stud and stud technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problem of low shear-resistant bearing capacity, and achieve the effects of saving materials, easy operation, and simple improvement methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

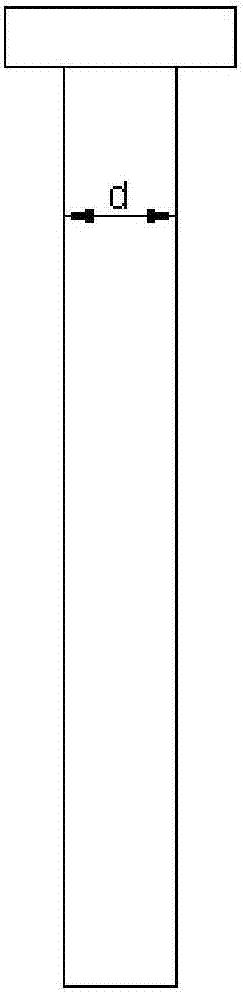

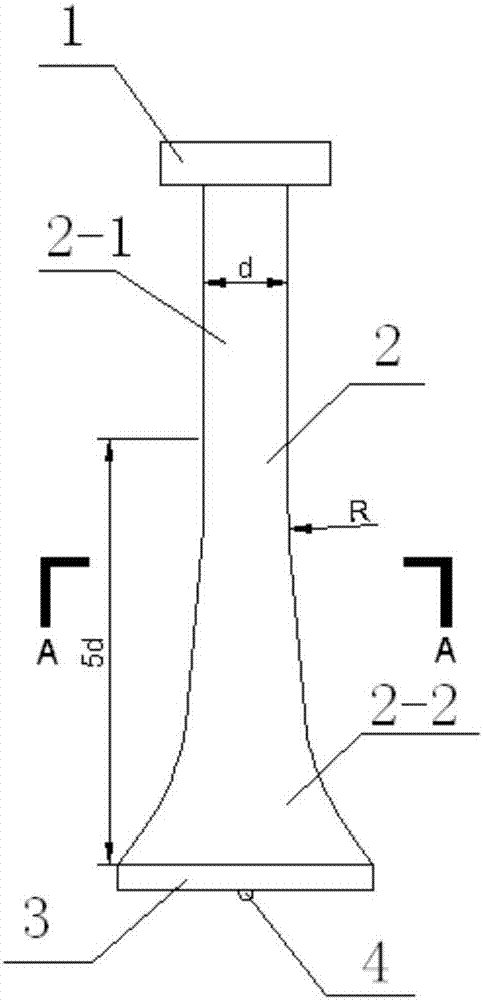

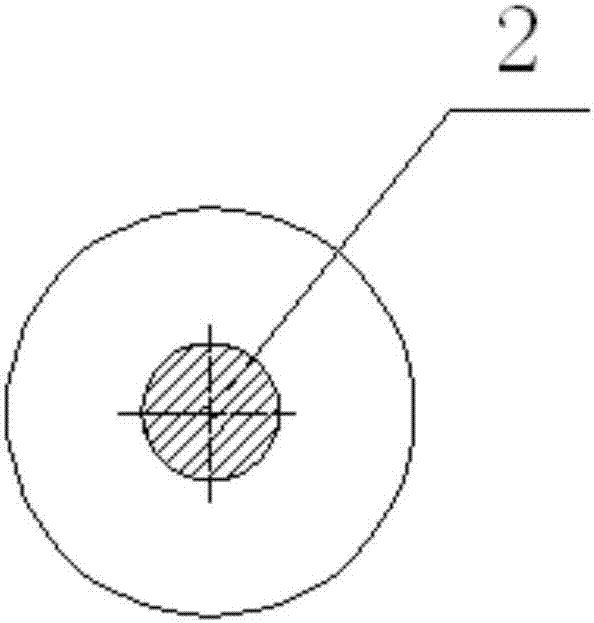

[0016] Specific embodiment 1: The shear stud of this embodiment includes a stud rod 2 and a cap 1, and a cap 1 is arranged on the top of the stud rod 2, and the diameter of the upper shaft 2-1 of the stud rod 2 is is d, the lower shaft 2-2 of the stud rod 2 is in the shape of a trumpet cone and the diameter of the shaft gradually increases with the axial direction downward of the stud rod, and the height of the lower shaft 2-2 of the stud rod 2 is 5d , The diameter of the bottom of the peg rod 2 is 2-2.5d, and the bottom of the peg rod 2 is also provided with a cylindrical bottom section 3 .

[0017] The peg rod, the peg cap and the bottom section of the cylinder described in this embodiment are integrally structured. Smooth rounded transition between upper shaft and lower shaft.

[0018] The shear studs in the steel-concrete composite structure of this embodiment design the optimization curve of the stud section diameter along the height through the finite element analysis, ...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that the diameter of the peg rod 2 is 1.2-1.4d at the height of the lower shaft 2-2 of the peg rod 2 at a height of d.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment differs from Embodiment 2 in that the diameter of the peg rod 2 is 1.1-1.2d at the height of the lower shaft 2-2 of the peg rod 2 at a height of 3d.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com