Primary mirror installation adjustment mechanism

An installation adjustment and mirror chamber technology, applied in installation, instrumentation, optics, etc., can solve the problems of mutual coupling between axial and radial directions, complex adjustment of the main mirror of the telescope, and poor stability, and achieve low axial stiffness, The effect of preventing position shift and simple adjustment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

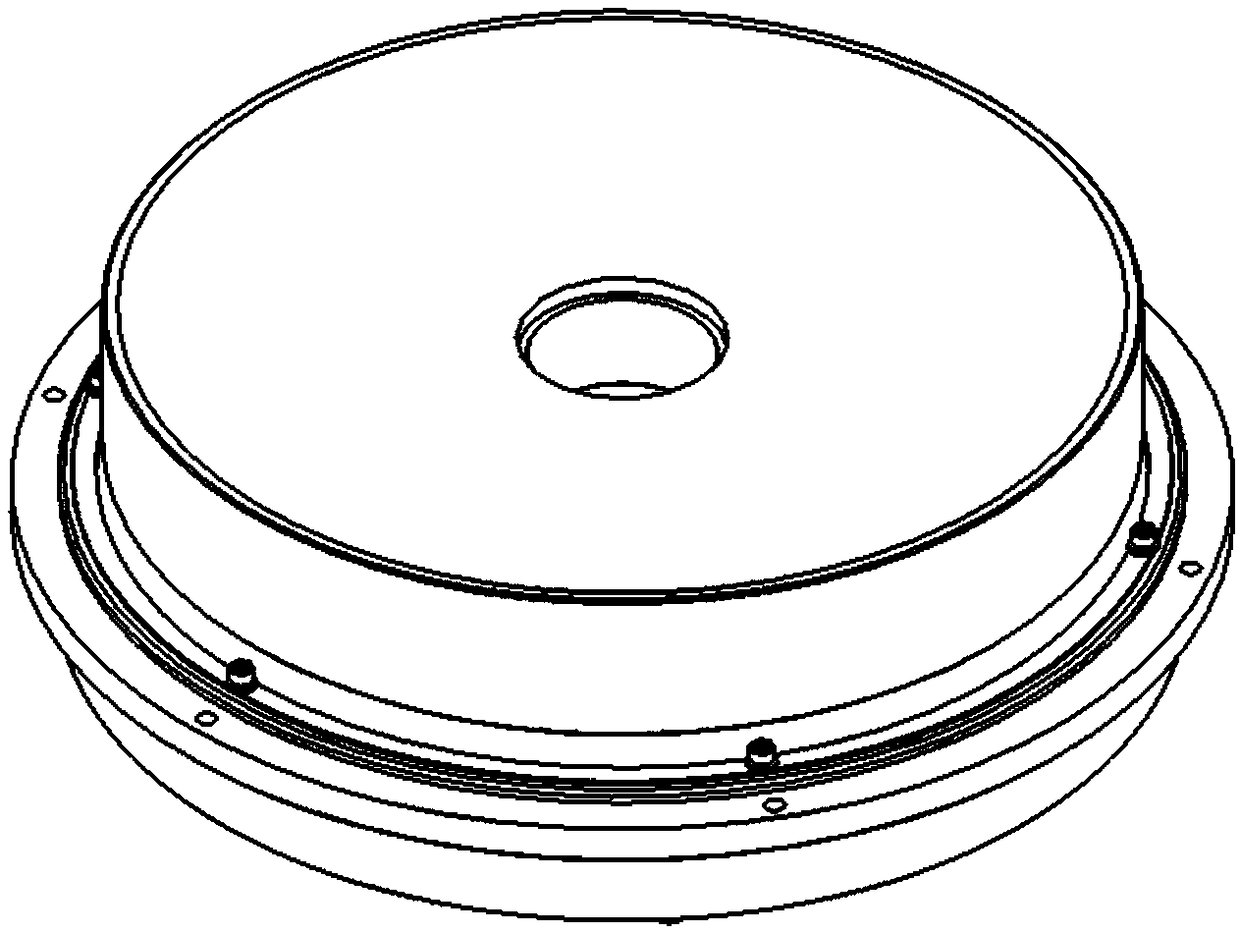

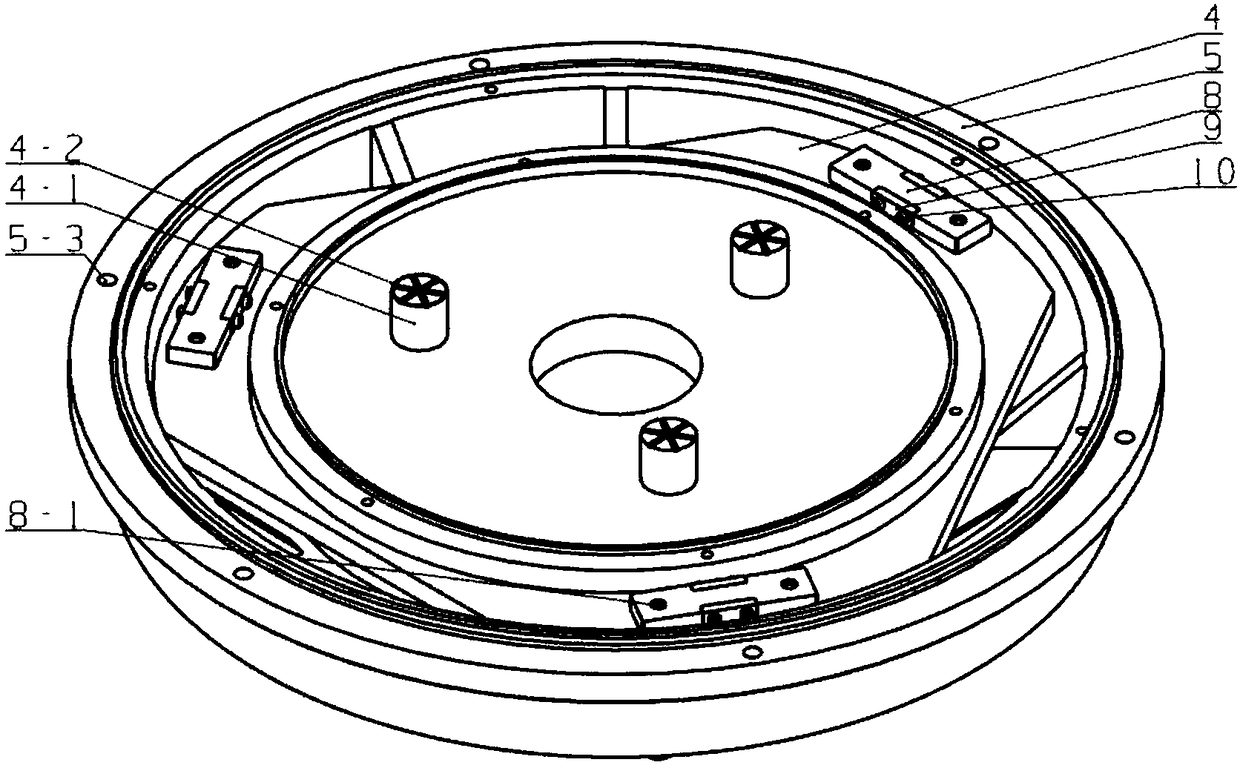

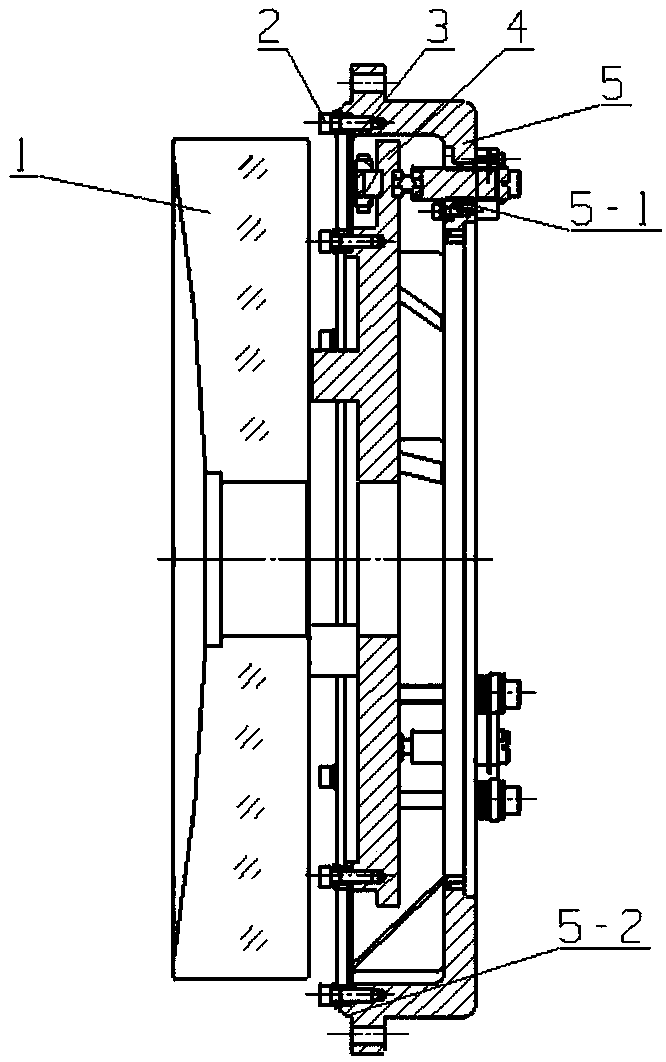

[0024] Specific implementation mode 1. Combination Figure 1 to Figure 7 Describe this embodiment, the main mirror installation adjustment mechanism, including the reflector 1, the support base 4, the main mirror chamber 5, the adjustment assembly connecting the main mirror chamber and the support base, the locking assembly, and the main mirror chamber and the support base. flexible diaphragm components such as image 3 and Figure 5 As shown, the reflector 1 is bonded to three support bosses 4-1 uniformly distributed on the support base, and the support points are provided with glue guide grooves 4-2. The support boss is located at 0.68 of the diameter of the bearing seat. The bottom of the primary mirror chamber 5 is provided with a through hole 5-1 opened at the bottom of the primary mirror chamber for connecting the primary mirror chamber 5 and the adjustment assembly. A through hole 5-3 for realizing the reference transfer, and for realizing the connection with the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com