Grating coupler and package structure thereof

A technology of a grating coupler and a packaging structure, applied in the field of optical communication, can solve the problems of inability to realize automatic and efficient alignment of optical fibers and gratings, incompatibility of the CMOS preparation process, and inability to carry out large-scale mass production, etc. Low, easy encapsulation, improved feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The grating coupler of the present invention will be further described in detail below with reference to the accompanying drawings.

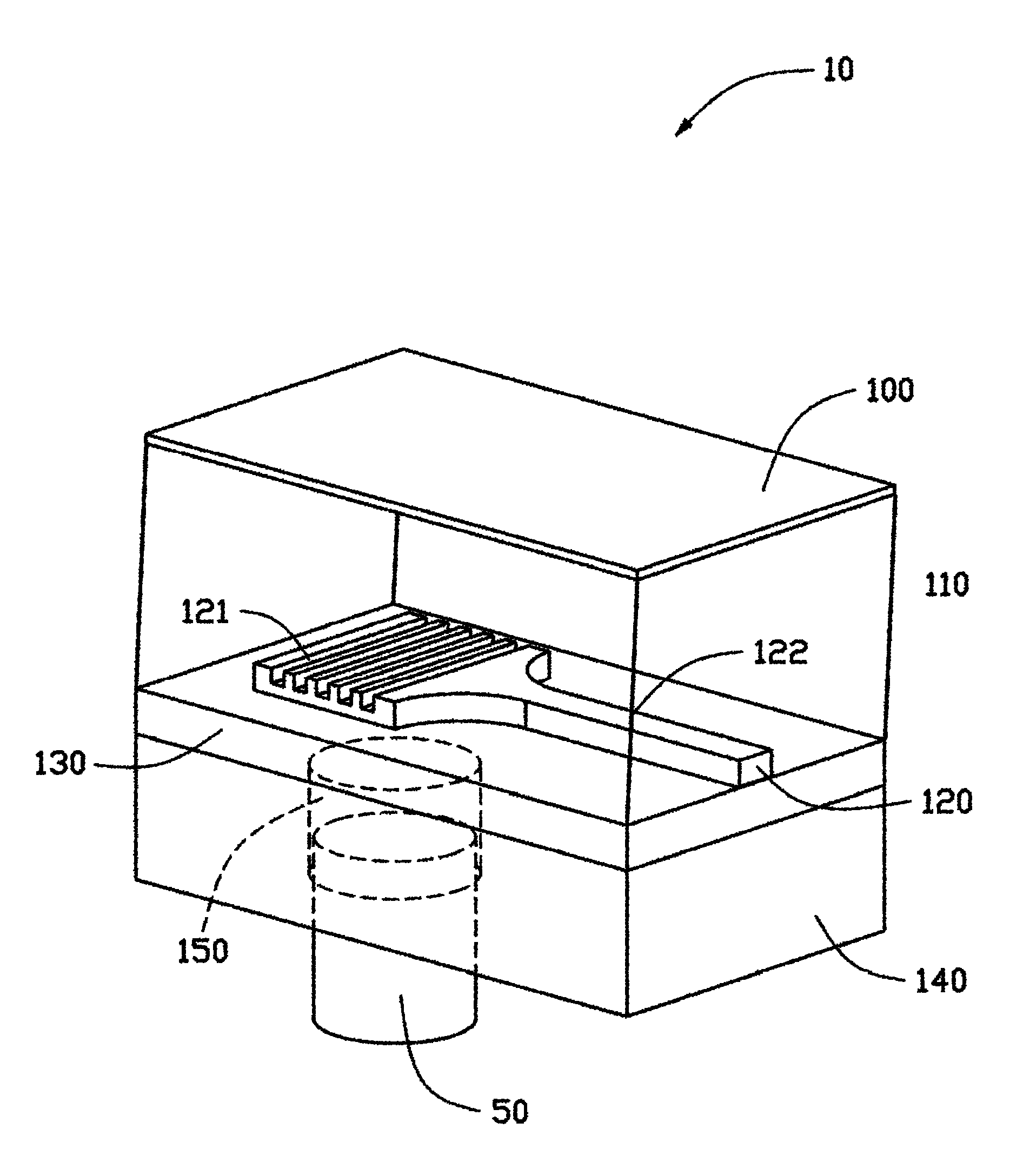

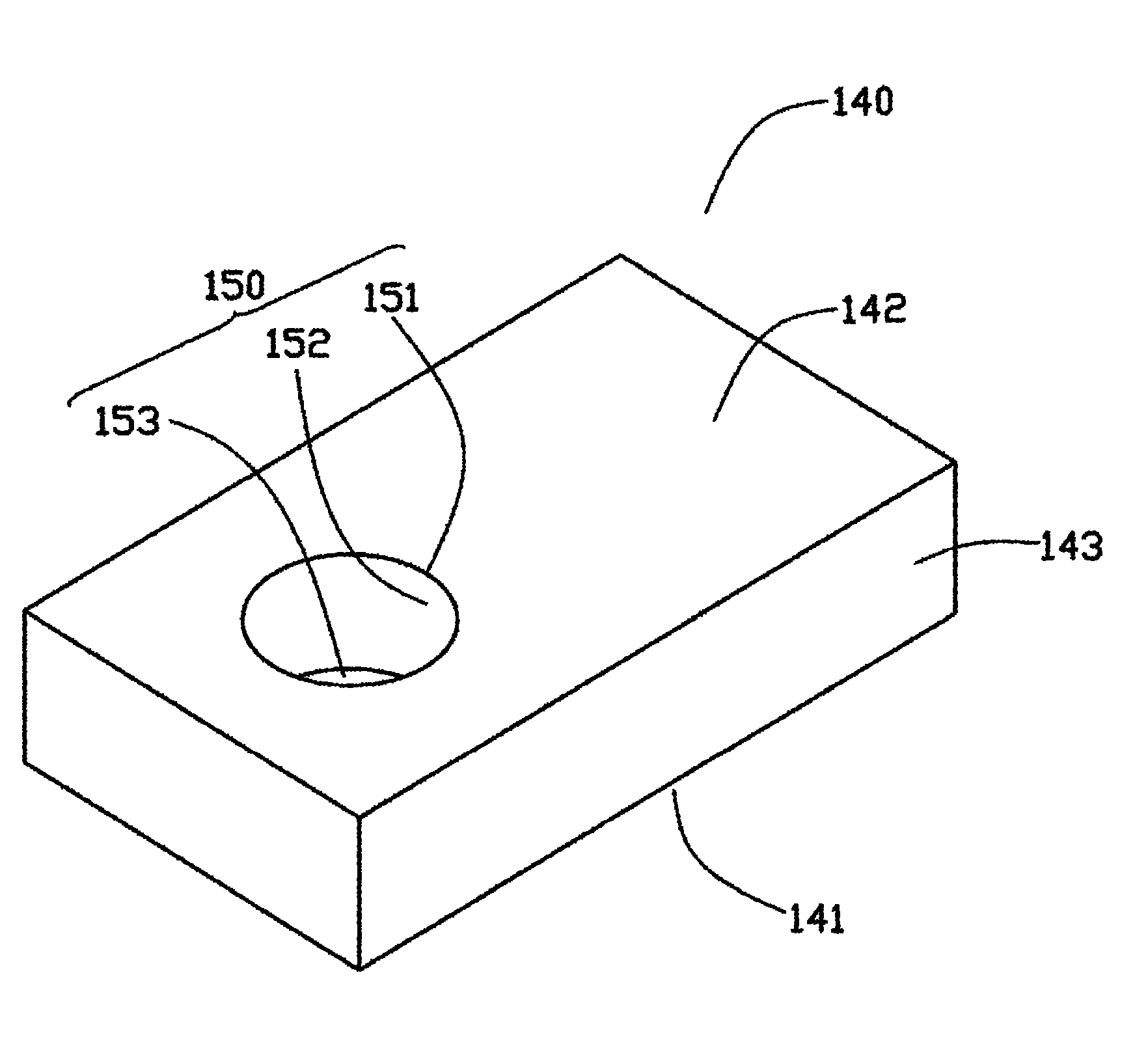

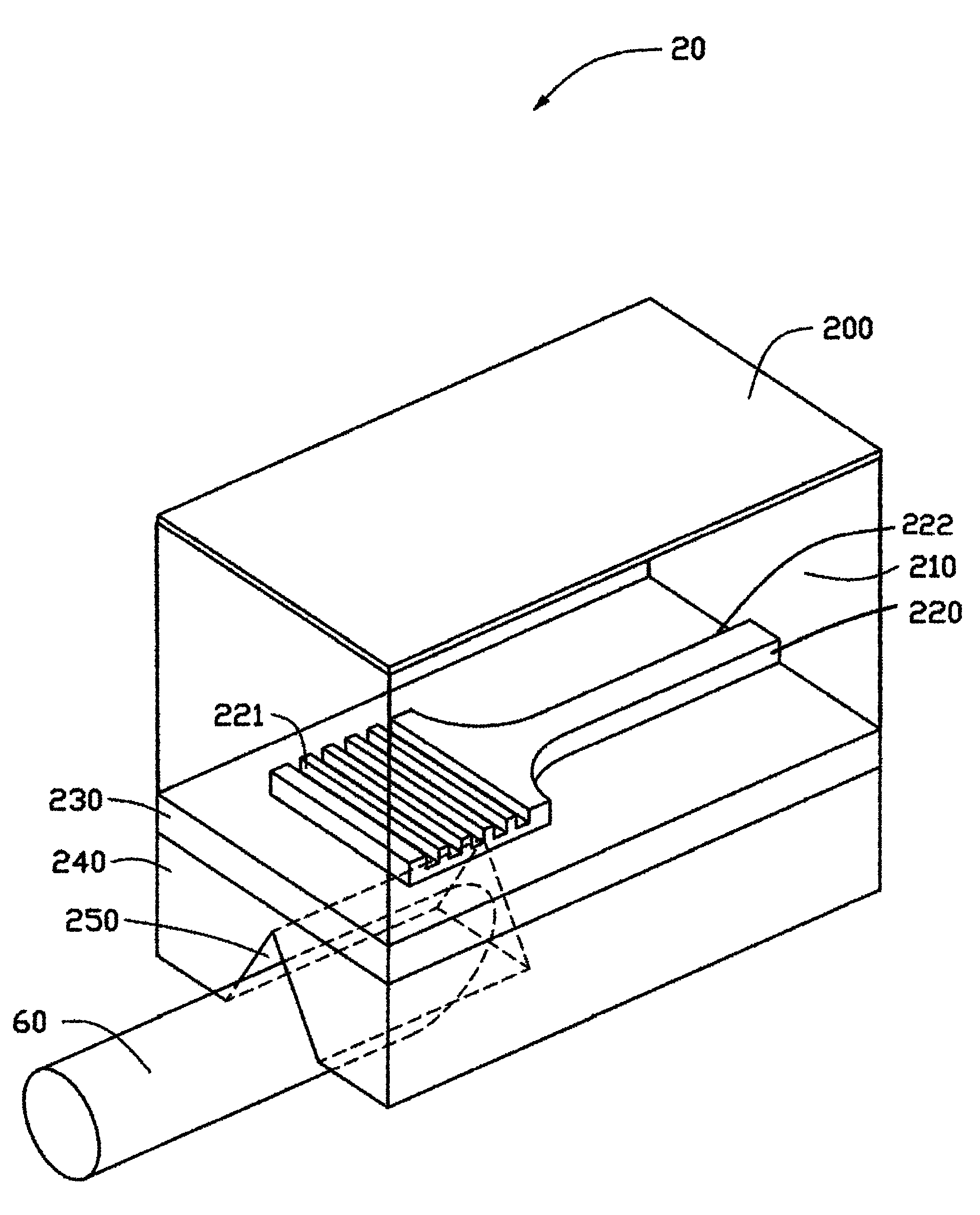

[0033] see figure 1 and figure 2 , the grating coupler 10 according to the first embodiment of the present invention includes a reflective layer 100 , an isolation layer 110 , a waveguide layer 120 , a lower cladding layer 130 and a substrate layer 140 . The substrate layer 140 has a first surface 141, a second surface 142 opposite to the first surface 141 and at least one third surface 143 connected to the first surface 141 and / or the second surface, assuming that the first surface 141 is called the front side, then the second surface 142 can be called the back side. The lower cladding layer 130 , the waveguide layer 120 , the isolation layer 110 , and the reflective layer 100 are sequentially stacked on the first surface 141 of the substrate layer 140 , and the reflective layer 100 is disposed on the surface of the isolation layer 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com