Infrared ruby lamp tube

A ruby, infrared technology, applied in the direction of heating element material, heating element shape, etc., can solve problems such as human body injury, and achieve the effect of enhancing transmittance and thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

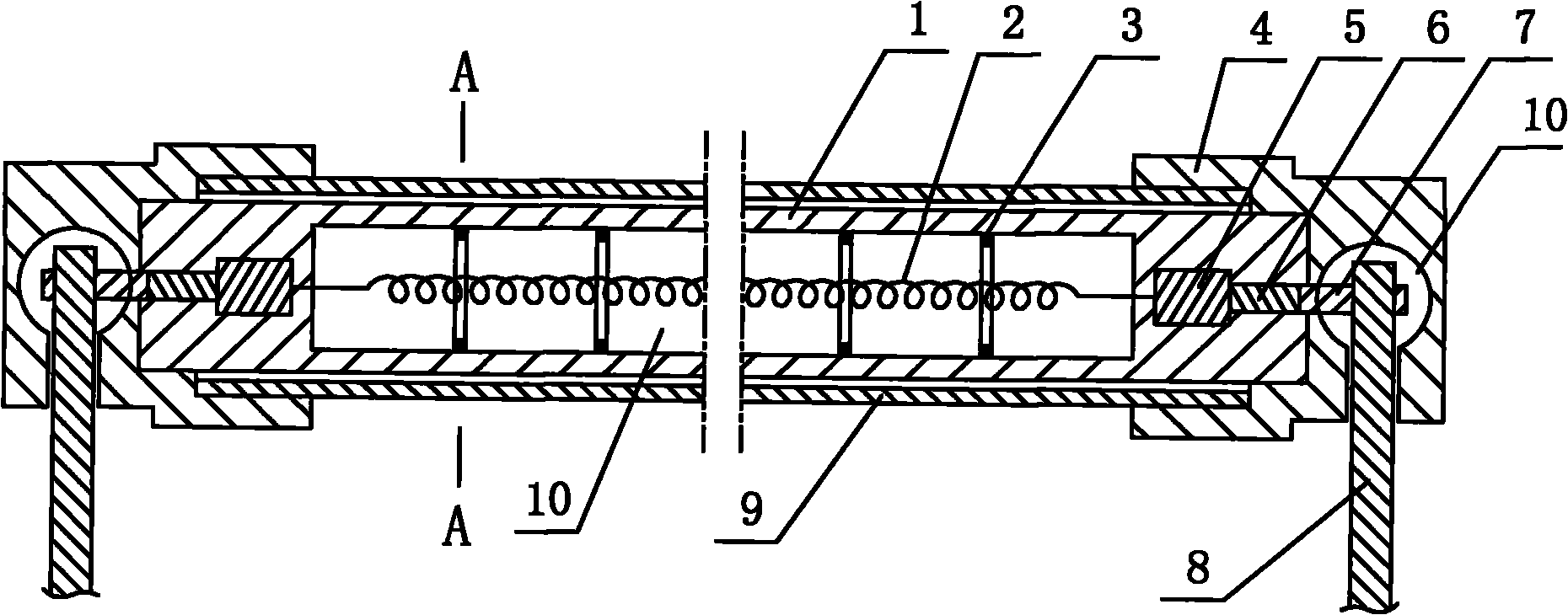

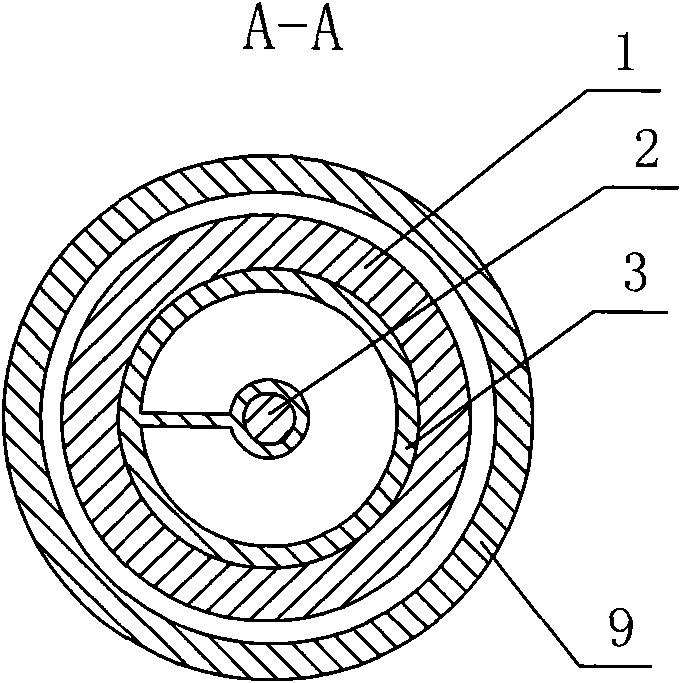

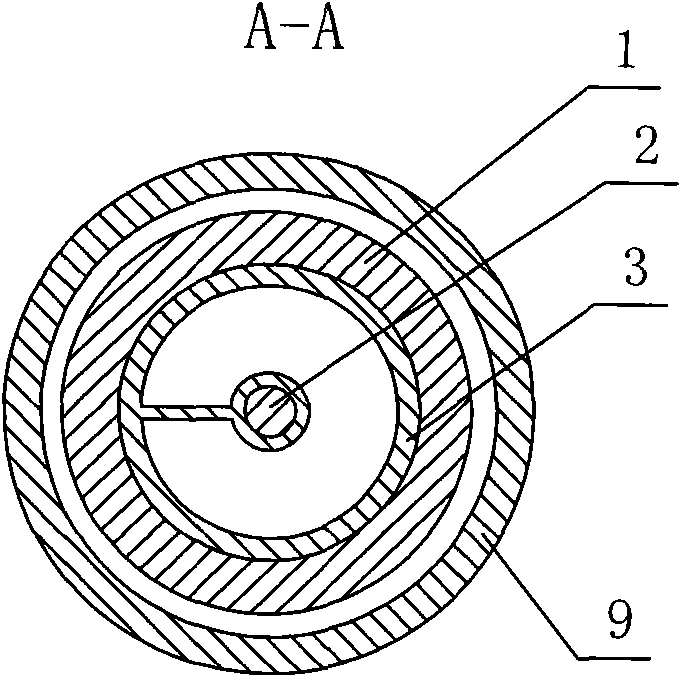

[0008] Such as figure 1 , 2 As shown, it is an infrared ruby lamp tube, which includes a transparent glass tube 1 with both ends sealed. An inert gas 10 is arranged in the glass tube 1. The two ends of the glass tube 1 are respectively provided with insulating mounting porcelain seats 4, and each insulating mounting porcelain seat 4 Through-holes 10 are respectively provided on them. A ruby glass tube 9 is sleeved outside the glass tube, and the two ends of the ruby glass tube 9 are respectively arranged in the insulating mounting porcelain seat 4.

[0009] A tungsten wire 2 is arranged inside the glass tube 1, and at least two bracket rings 3 are connected to the tungsten wire 2 at intervals. The two ends of the tungsten wire 2 are respectively spot-welded with the molybdenum sheet 5, the other end of each molybdenum sheet 5 is respectively spot-welded with the molybdenum rod 6, the other end of each molybdenum rod 6 is spot-welded with the stainless steel terminal 7,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap