Fly indoor scale feeding room

A flies and house technology, applied in the field of rearing houses, can solve the problems of outdoor flies, safety, and easy escape of adult flies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

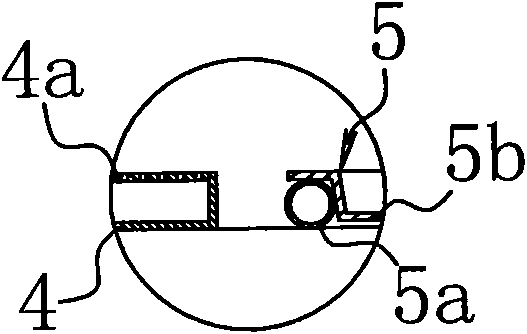

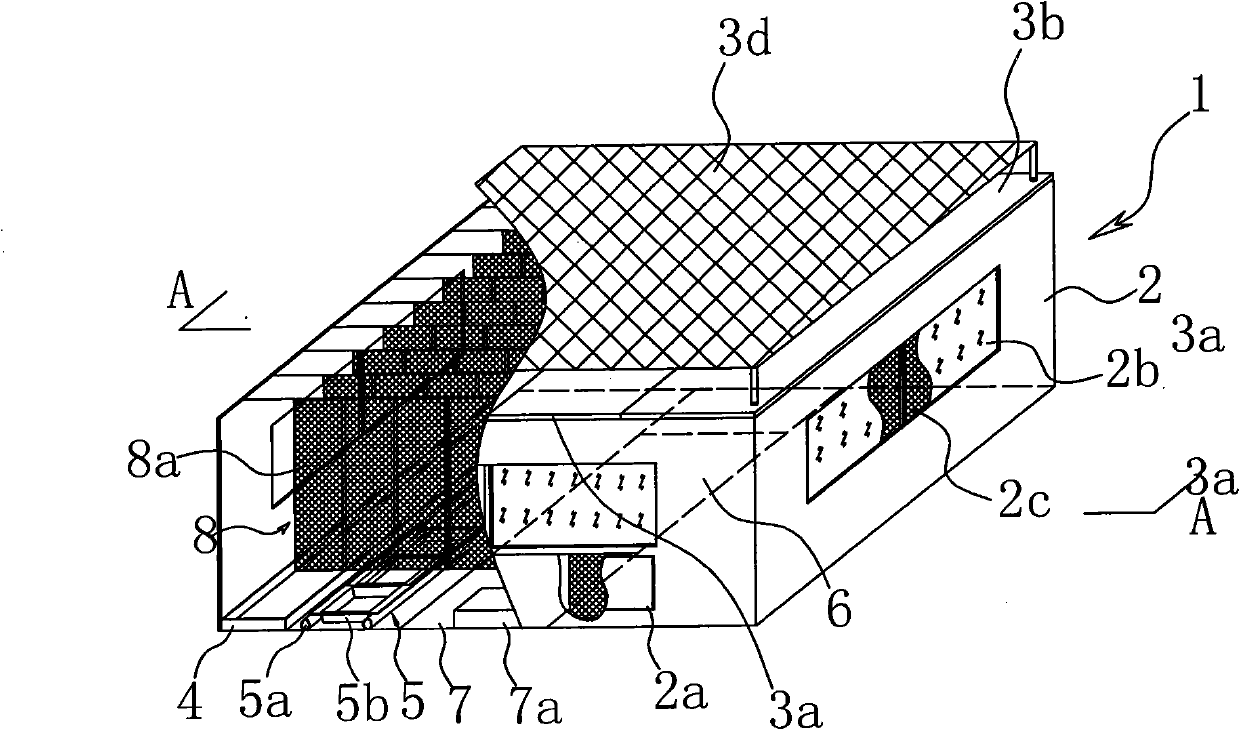

[0031] refer to Figures 1 to 4 As shown, a kind of indoor large-scale breeding house for flies of the present invention comprises a length of 4 to 6m, a width of 3 to 5m, and a height of 2 to 3m. 3 structure, in this embodiment, the facade 2 is made of double-layer insulation boards, and the roof 3 is formed of transparent tiles 3a and double-layer insulation tiles 3b arranged at intervals, so that the natural light can be fully utilized to make the indoor light good and save It reduces the cost of lamp lighting; it can also play a role in regulating temperature and humidity, and can prevent the temperature difference in the room from changing too quickly. Water tanks 4 are respectively arranged on the ground on the left and right sides of the inside of the room body 1, and plastic rubber pads 4a are laid on the water tanks 4, which not only provide places for flies to drink, but also play a role in regulating indoor temperature and humidity; lure eggs Road 5 is located side...

Embodiment 2

[0033] refer to Figure 5As shown, a kind of fly indoor large-scale breeding room of the present invention, its structure is basically the same as that of Embodiment 1, the difference is that the docking member 8 is made up of a plurality of hanging pieces 8b suspended on the roof 3, and the hanging pieces 8b can be separated The ground is connected in a row and neatly arranged in the room body 1 at intervals, and can also be distributed in the room body 1 at random intervals. In this embodiment, the neat arrangement is preferred, which can facilitate the operation of the staff. Adjacent The distance between the two rows of hanging pieces 8b, between the hanging piece 8b and the ground, and between the hanging piece 8b and the facade 2 is 30-50cm. Its effect is identical with the mesh bar 8a of embodiment 1, is all in order to increase the effective area that flies stop indoors, thereby increasing the density and scale of breeding. In addition to the above two forms of dockin...

Embodiment 3

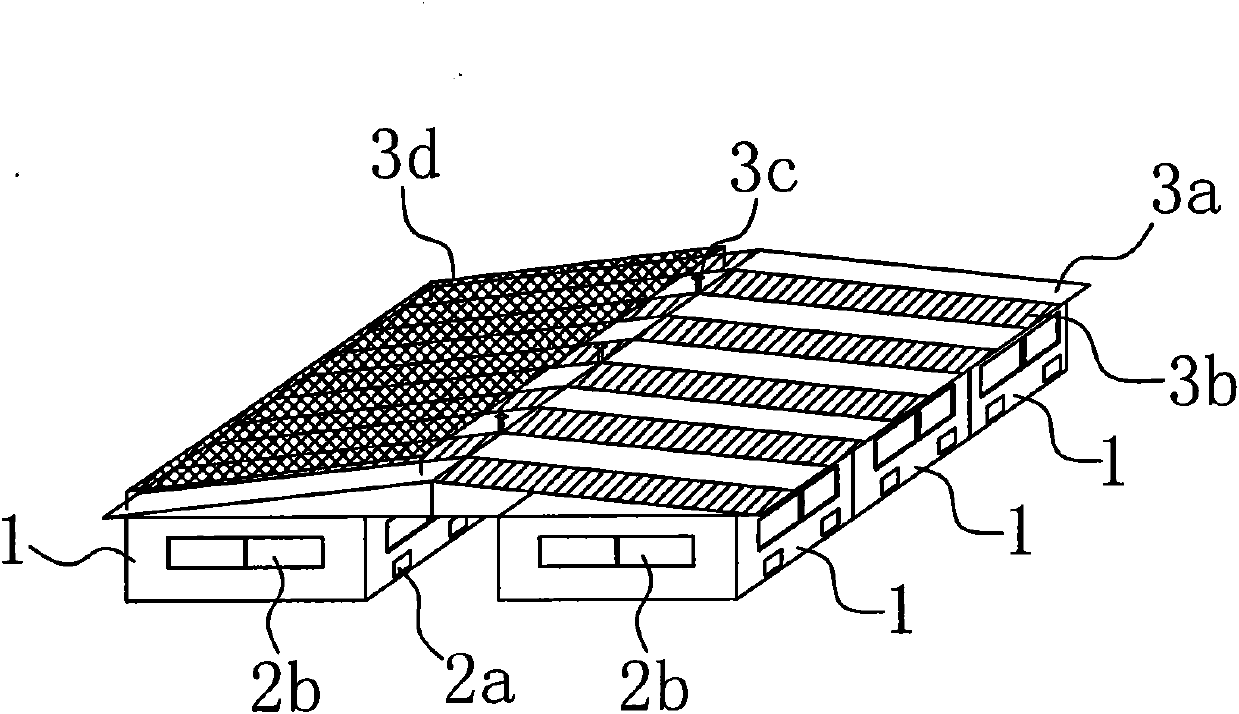

[0035] refer to Figure 6 As shown, it is a reference diagram of the use state of the present invention. What is shown in the figure is that a plurality of fly indoor large-scale breeding rooms of the present invention are arranged side by side in two rows, and a feeding channel is set in the middle, and an integral roof is adopted. The water head 3c and the sunscreen net 3d are also uniformly arranged, which is more convenient for management and operation, so that the breeding of flies can be industrialized; of course, the indoor large-scale breeding room for flies of the present invention can also be combined in other ways, such as being stacked into double layers or more layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com