Circular pressing device of pressure-bearing solar water heater heat collection plate

A technology of solar water heater and heat collecting plate, applied in the field of heat generation and utilization, can solve the problems of complex processing technology, stress concentration, increased production cost, etc., and achieve the effects of simple operation, high pressure bearing limit, and reduction of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

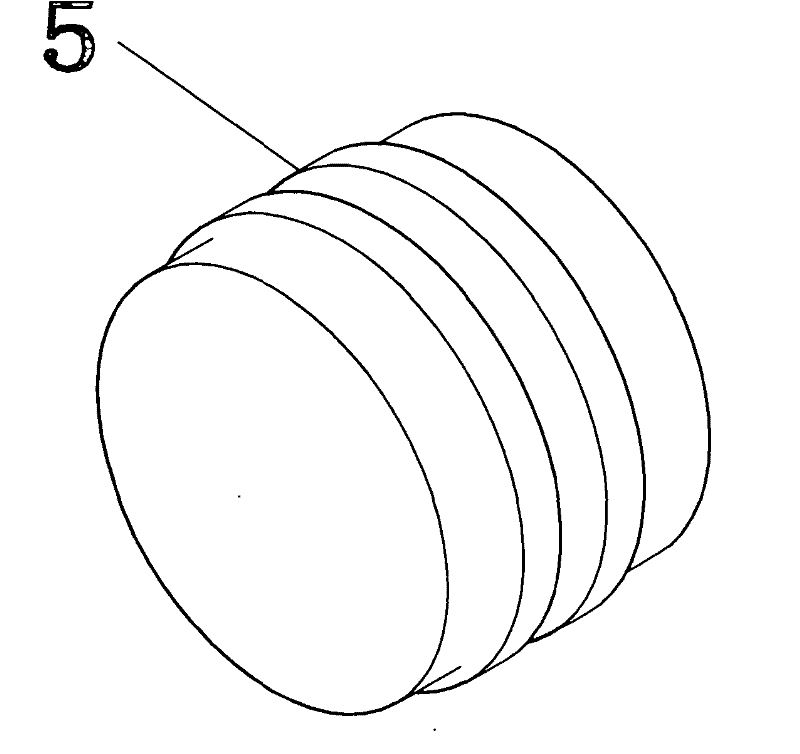

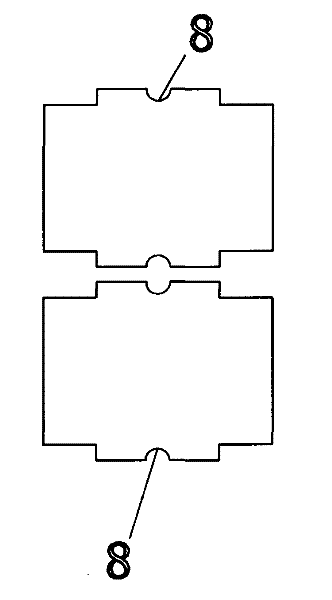

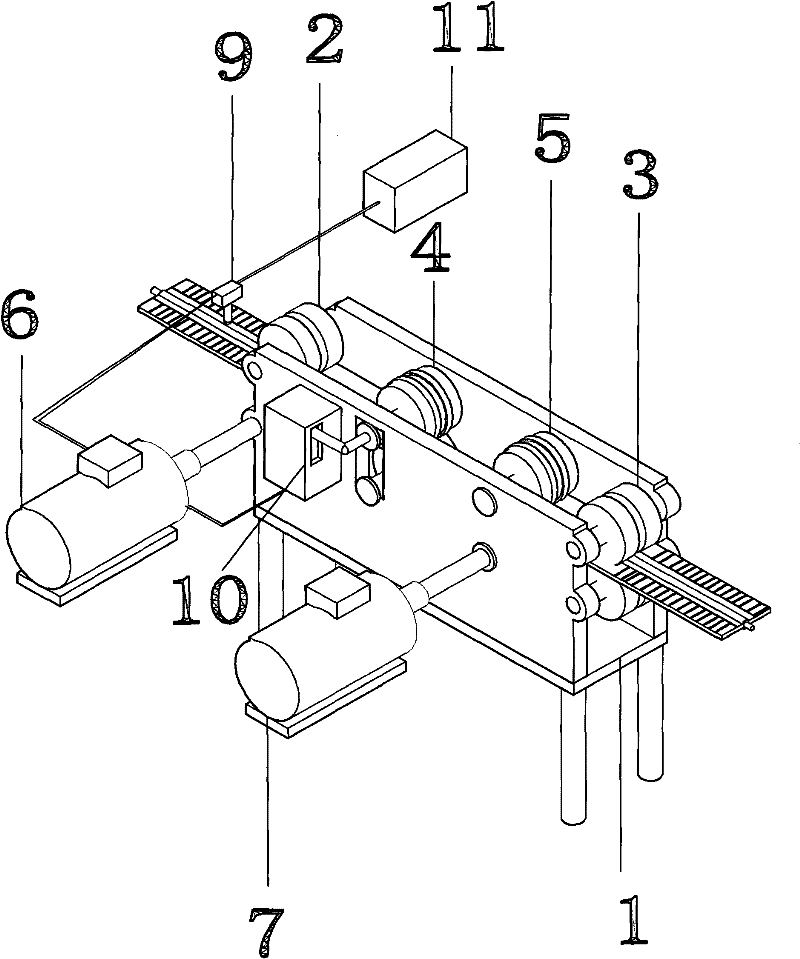

[0028] The radius of the small part of the cylinder at both ends of the rounding wheel is 99 mm, and the position is at the place where the semicircle groove 8 in the middle of each rounding wheel set 4 and the back rounding wheel set 5 extends 11 mm from the tangent point of the circumference to both sides. Width is 13mm; Front drive motor 6 links to each other with the axle of front rubber wheel set 2, and rear drive motor 7 links to each other with the axle of rear pressure circle wheel set 5.

[0029] The pre-made semi-finished heat collecting plate is sent to the front rubber wheel group 2, and the first pressing round wheel group 4 of the pressure-bearing solar water heater heat collecting plate rounding device is used to close the seam for the first time, so that the soft aluminum strip and The pre-embedded pipe is attached to the outer surface of the hard tributary copper pipe, and then with the thrust of the front drive motor 6, the heat collecting plate is sent to the...

Embodiment 2

[0032] The radius of the small part of the cylinder at both ends of the rounding wheel is 149.2mm, which is located at the semicircular groove 8 in the middle of each rounding wheel set 4 and the back rounding wheel set 5 and extends 10.5mm to both sides. Place, width is 12mm; Front drive motor 6 links to each other with the axle of front rubber wheel set 2, and rear drive motor 7 links to each other with the axle of rear pressure circle wheel set 5.

[0033]A travel switch 9 is arranged in front of the front rubber wheel group 2 of the device, and the travel switch 9 is connected with the regulating mechanism 10 controlling the front pressure round wheel group 4 to control the distance between the two pressure round wheels; the lower contact point of the travel switch 9 There is a distance of 0.5mm between the blank parts on both sides of the pre-embedded pipe of the semi-finished heat collector plate with qualified quality. If there are defects such as bending and deformation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com