Production technology of pressure type solar water heater heat-collecting plate

A technology of solar water heater and production process, which is applied in solar thermal power generation, solar thermal device, heating device and other directions, can solve the problems of reducing production cost and low pressure bearing capacity of solar water heater collector plate, so as to reduce production cost and reduce water leakage. The effect of the ratio of , high pressure limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

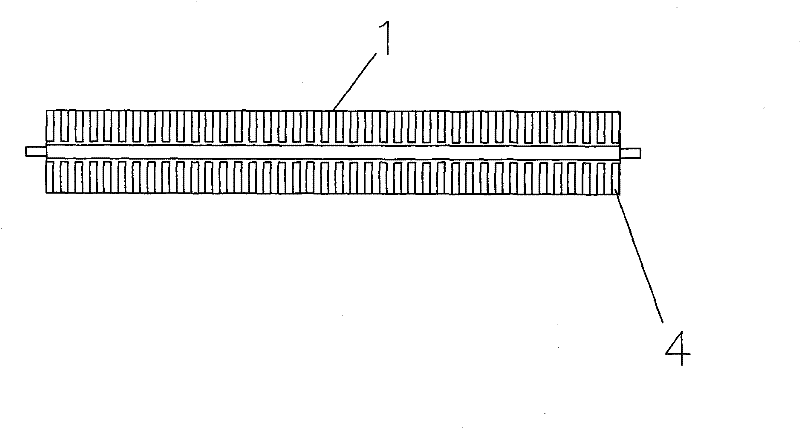

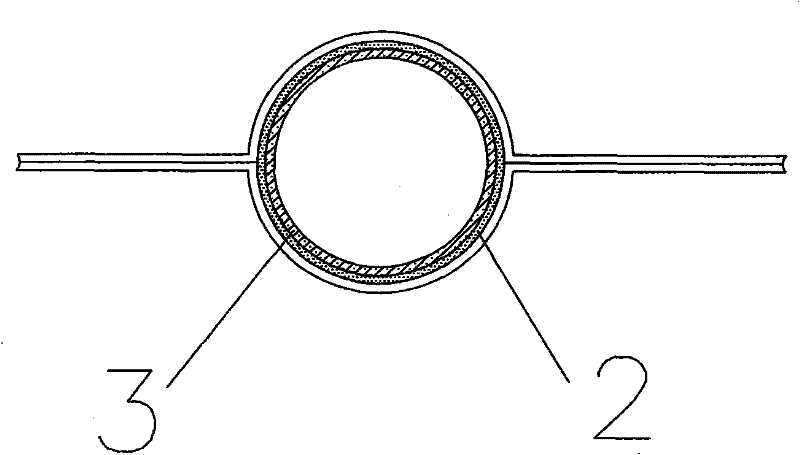

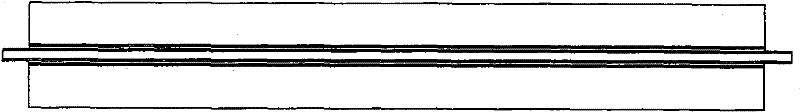

[0024] Such as figure 1 , 2 . As shown in 3, a pressure-bearing solar water heater collector plate, including aluminum strip (1), embedded pipe (2), is characterized in that: a branch copper pipe (3) is pierced in the embedded pipe (2) .

[0025] The embedded pipe (2) is a TP2 soft copper pipe, and the tributary copper pipe (3) is a TP2 hard copper pipe.

[0026] A pressure-bearing solar water heater heat collector. The production process is as follows: the soft pre-embedded pipe (2) undergoes straightening, preloading, overall oxidation film removal, and dust removal treatment, and is sandwiched between two pipes that have undergone oxidation film removal and dust removal treatments. between the aluminum strips (1), and then press the aluminum strip (1) and the pre-compressed embedded pipe (2) together through the pressing shaft, and use the mold to press the pressed aluminum strip (1) to strengthen Ribs (4), after winding, carry out alkali washing, pickling, oxidation an...

Embodiment 2

[0028] Such as figure 1 , 2 . As shown in 3, a pressure-bearing solar water heater collector plate, including aluminum strip (1), embedded pipe (2), is characterized in that: a branch copper pipe (3) is pierced in the embedded pipe (2) .

[0029] The embedded pipe (2) is a soft aluminum pipe, and the tributary copper pipe (3) is a TP2 hard copper pipe.

[0030] A pressure-bearing solar water heater heat collector, the production process is as follows: the soft pre-embedded aluminum tube (2) undergoes straightening, pre-pressing, overall oxidation film removal, and dust removal treatment, and is sandwiched between two tubes that have undergone oxidation film removal, dust removal Between the processed aluminum strips (1), the aluminum strip (1) and the pre-compressed embedded pipe (2) are pressed together through the pressing shaft, and the pressed aluminum strip (1) is pressed out using a mold Reinforcing ribs (4), after winding, carry out alkali washing, pickling, oxidati...

Embodiment 3

[0032] Such as figure 1 , 2 . As shown in 3, a pressure-bearing solar water heater collector plate, including aluminum strip (1), embedded pipe (2), is characterized in that: a branch copper pipe (3) is pierced in the embedded pipe (2) .

[0033] The embedded pipe (2) is a soft aluminum pipe, and the tributary copper pipe (3) is a semi-hard copper pipe.

[0034] A pressure-bearing solar water heater heat collector, the production process is as follows: the soft pre-embedded aluminum tube (2) undergoes straightening, pre-pressing, overall oxidation film removal, and dust removal treatment, and is sandwiched between two tubes that have undergone oxidation film removal, dust removal Between the processed aluminum strips (1), the aluminum strip (1) and the pre-compressed embedded pipe (2) are pressed together through the pressing shaft, and the pressed aluminum strip (1) is pressed out using a mold Reinforcing ribs (4), after winding, carry out alkali washing, pickling, oxidat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com