Cutting machine for metal tube

A pipe cutting machine and metal pipe technology, applied in the direction of metal sawing equipment, metal processing equipment, sawing machine equipment, etc., can solve the problems of metal pipe beveling and deformation, metal pipe synchronous horizontal movement, etc., to prevent beveling and deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

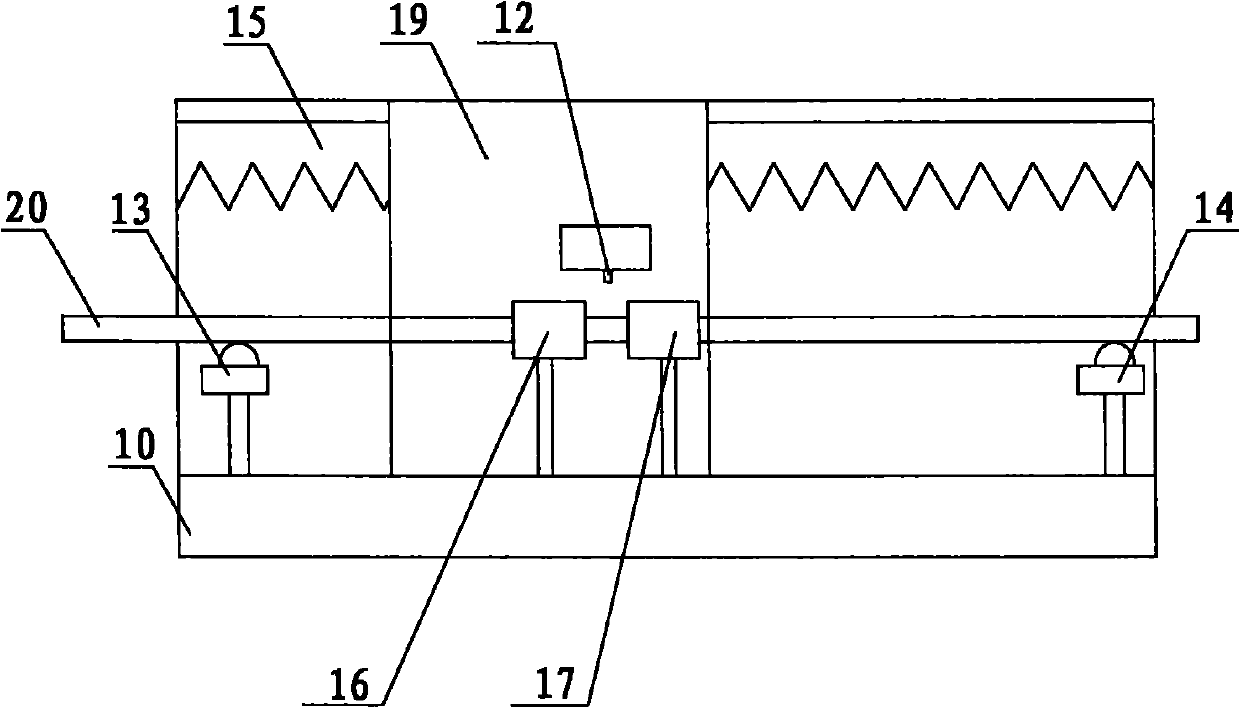

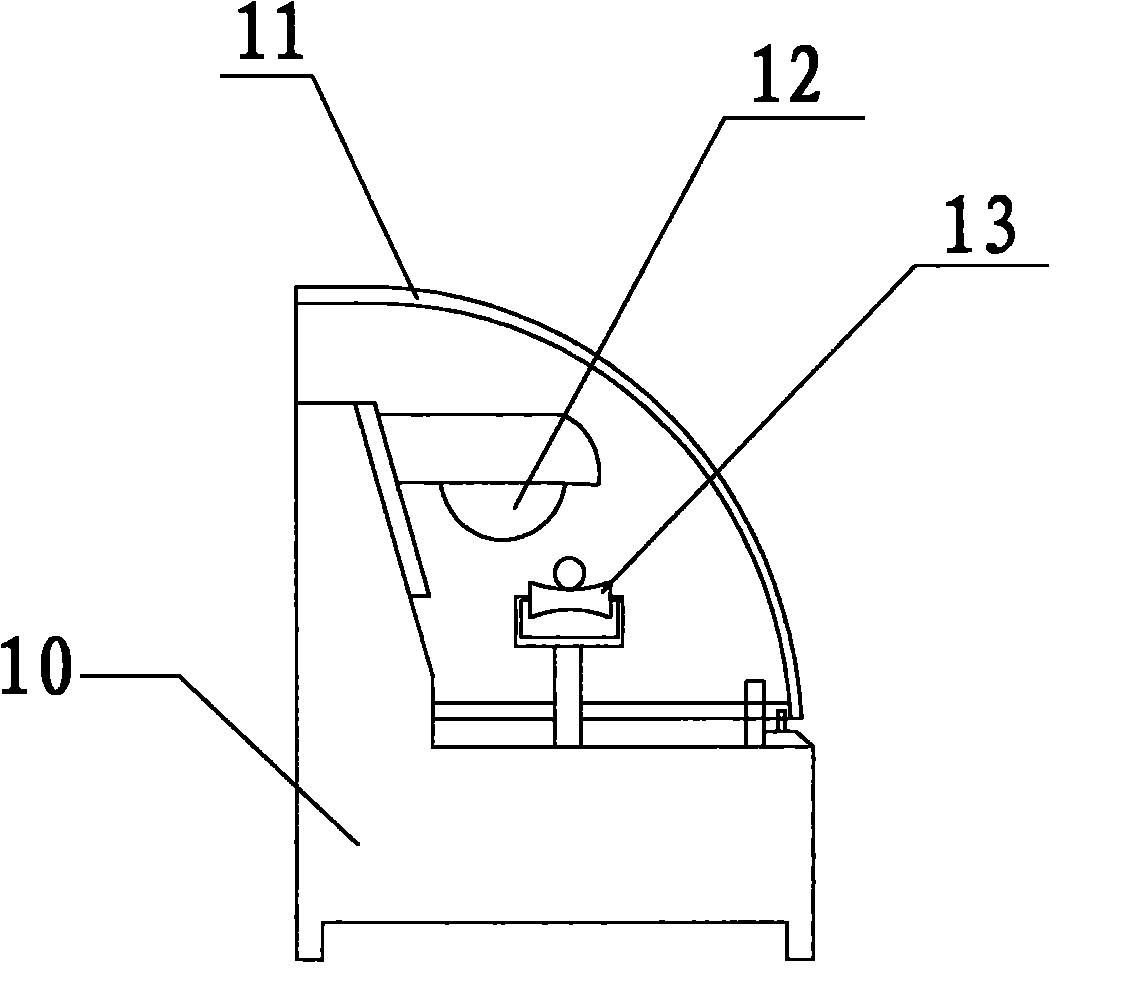

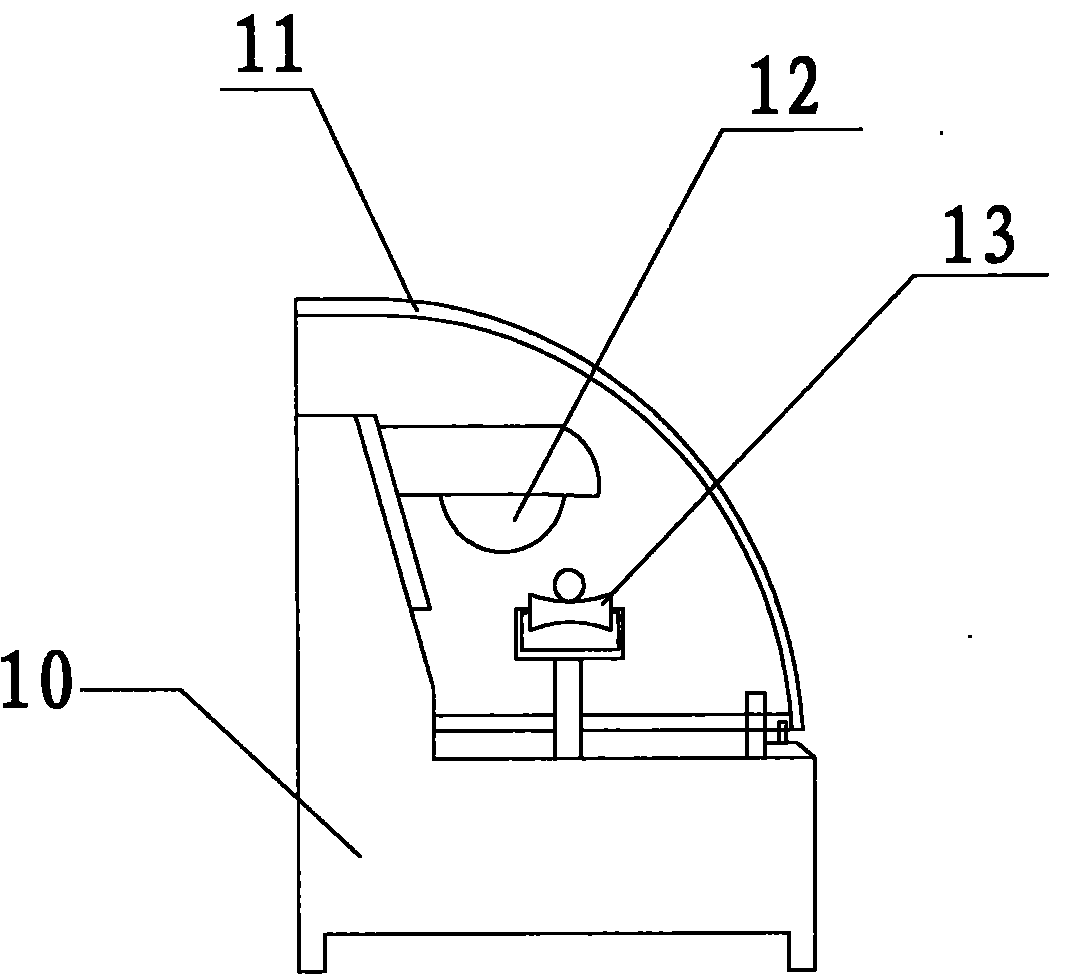

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 with figure 2 As shown, a metal pipe cutting machine includes a vertically long machine base 10, and the two ends of the machine base 10 are horizontally provided with a first support frame 13 and a second support frame 14 for supporting the metal pipe 20 to be cut. A box body 11 is also movably arranged on the base 10 , and the box body 11 is located between the first support frame 13 and the second support frame 14 .

[0013] Both sides of the box body 11 are open structures, and the metal pipe 20 can penetrate into the box body 11 from the open opening on one side of the box body 11 and then pass out from the open opening on the other side of the box body 11. The front side of the box body 11 is provided with Glass protective cover 19 is arranged.

[0014] The first clamp 16 and the second clamp 17 are fixedly arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com