Manual nailing gun

A nail gun, manual technology, applied in the field of manual nail gun, can solve the problem of labor and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

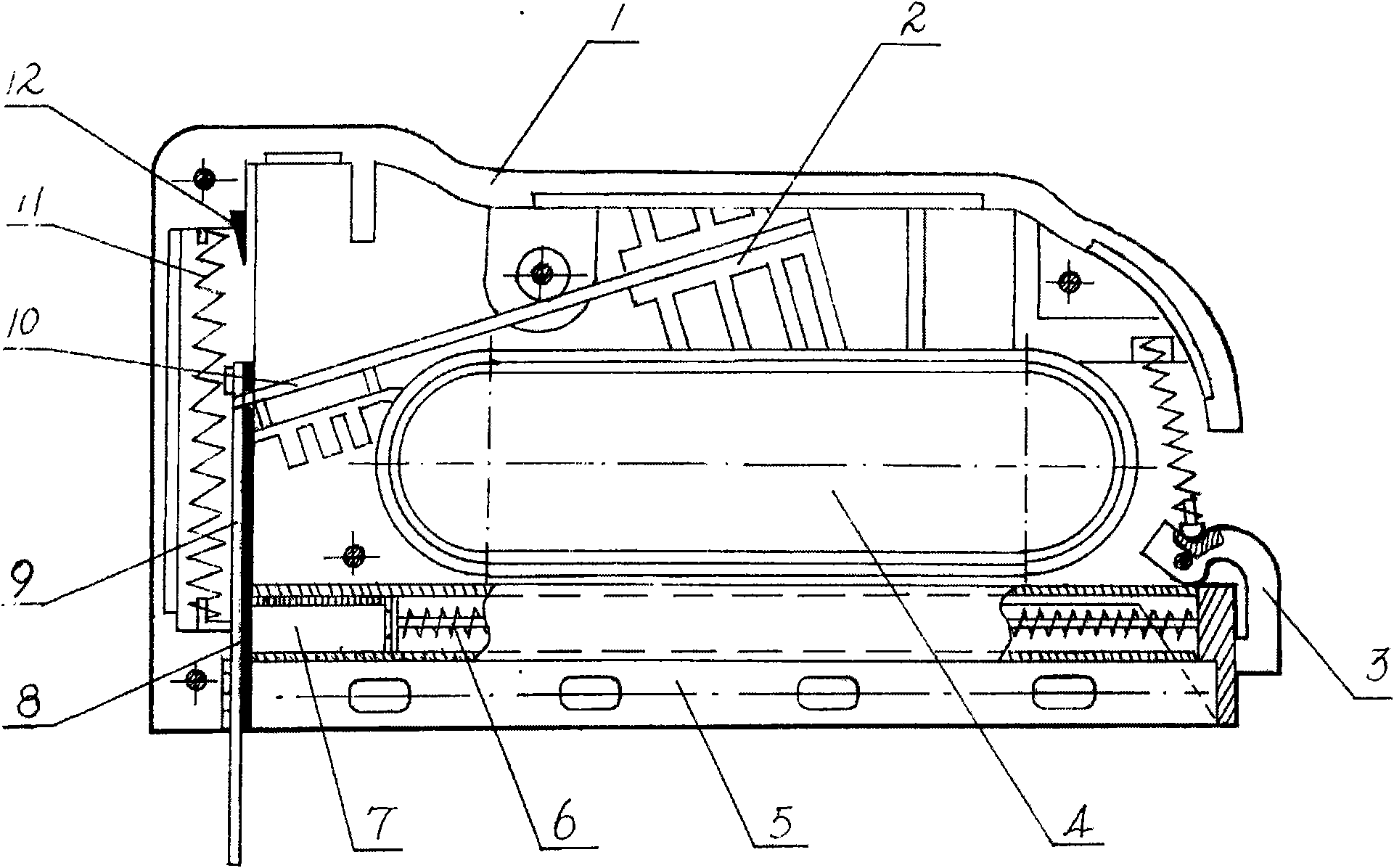

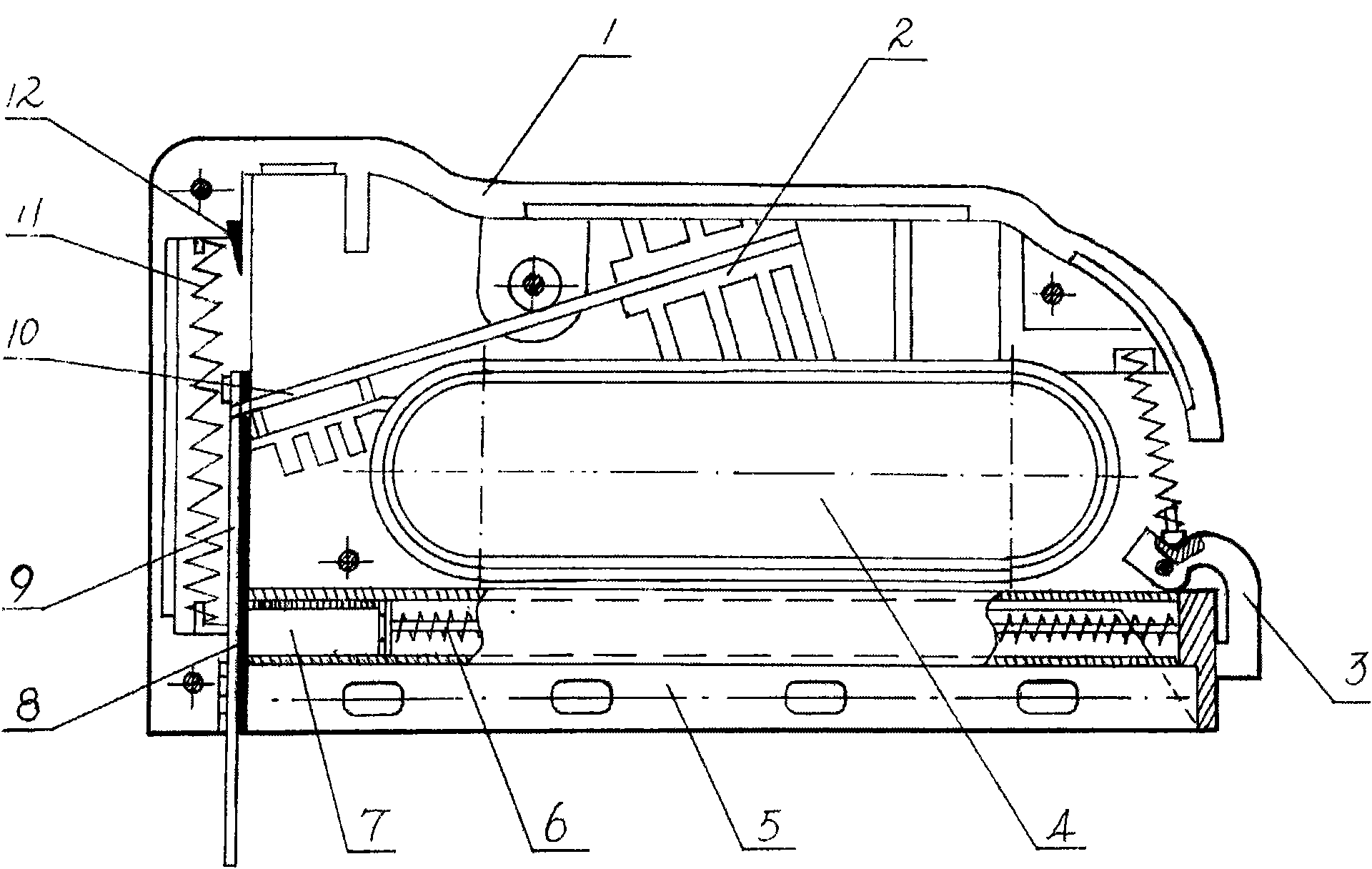

[0007] See attached figure 1 , the present invention comprises casing 1, three sets of spring devices in the casing, rear card 3 and handshake hole 4 are arranged on the casing, one of three sets of spring devices is nail box 7 and push rod spring nail feeding device 6, nail box and nail feeding device The device is mounted on the base 5, the second spring device is the top plate 9 and the spring nailing device, the spring nailing device is close to the impact spring 8 of the nail box 7, the shrapnel 10 and the ejector pin 12 located at the top of the impact spring moving groove, One end of the shrapnel 10 is connected with the impact spring, and the other end is fixed on the shrapnel seat 2. The third spring device is the top piece return spring device. The top piece return spring device includes the top piece and the return spring 11. It is connected with the impact spring with an elastic pin. The operation process of this manual nail gun is that the builder holds the nail g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com