Steel wire mesh cylinder with preformed hole and method for carrying out steel bar connection

A technology of steel wire mesh and reserved holes, which is applied to structural elements, building components, building reinforcements, etc., can solve problems such as affecting the production process, and achieve the effect of requiring power consumption, easy construction quality assurance, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

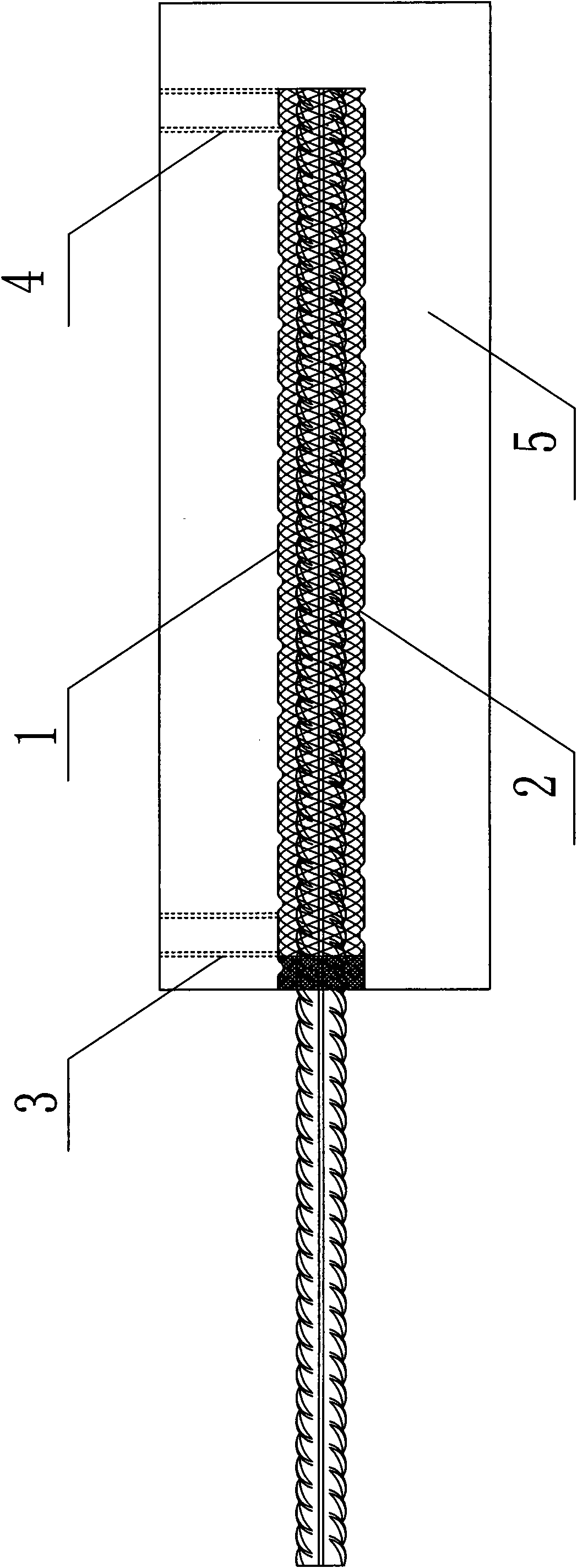

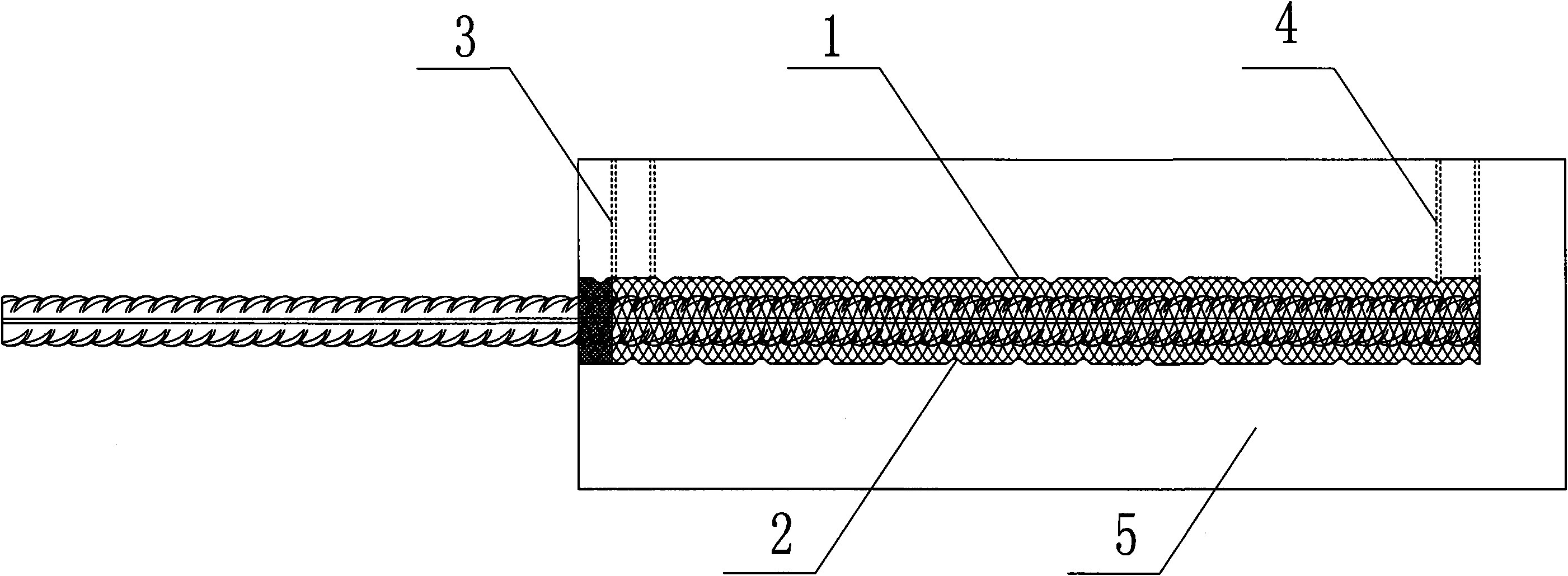

[0013] A steel mesh cylinder with reserved holes, its composition includes: a steel mesh cylinder 1, one end of the steel mesh cylinder is open and one end is closed, and there is a spiral groove 2 outside the cylinder, and the steel mesh cylinder is There is an air outlet 4 connected to the inside of the cylinder near the closed end on the cylinder, and a grouting hole 3 connected to the inside of the cylinder on the steel mesh cylinder near the open end, and the opening of the steel mesh cylinder is embedded in the Interior of precast concrete 5.

Embodiment 2

[0015] The steel mesh cylinder with reserved holes is used to connect steel bars. The process is: pre-embed the steel mesh cylinder with the opening outward in the prefabricated concrete, insert the steel bars into the open end and seal it, and then install it from the grouting hole Grouting is carried out, and the vent hole naturally discharges air, thereby carrying out reinforcement anchorage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com