Vacuum device

A vacuum equipment and low-vacuum technology, applied in the direction of mechanical equipment, liquid variable displacement machinery, machines/engines, etc., can solve the problems of multiple energy sources, increase the maintenance cost of vacuum equipment 100, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

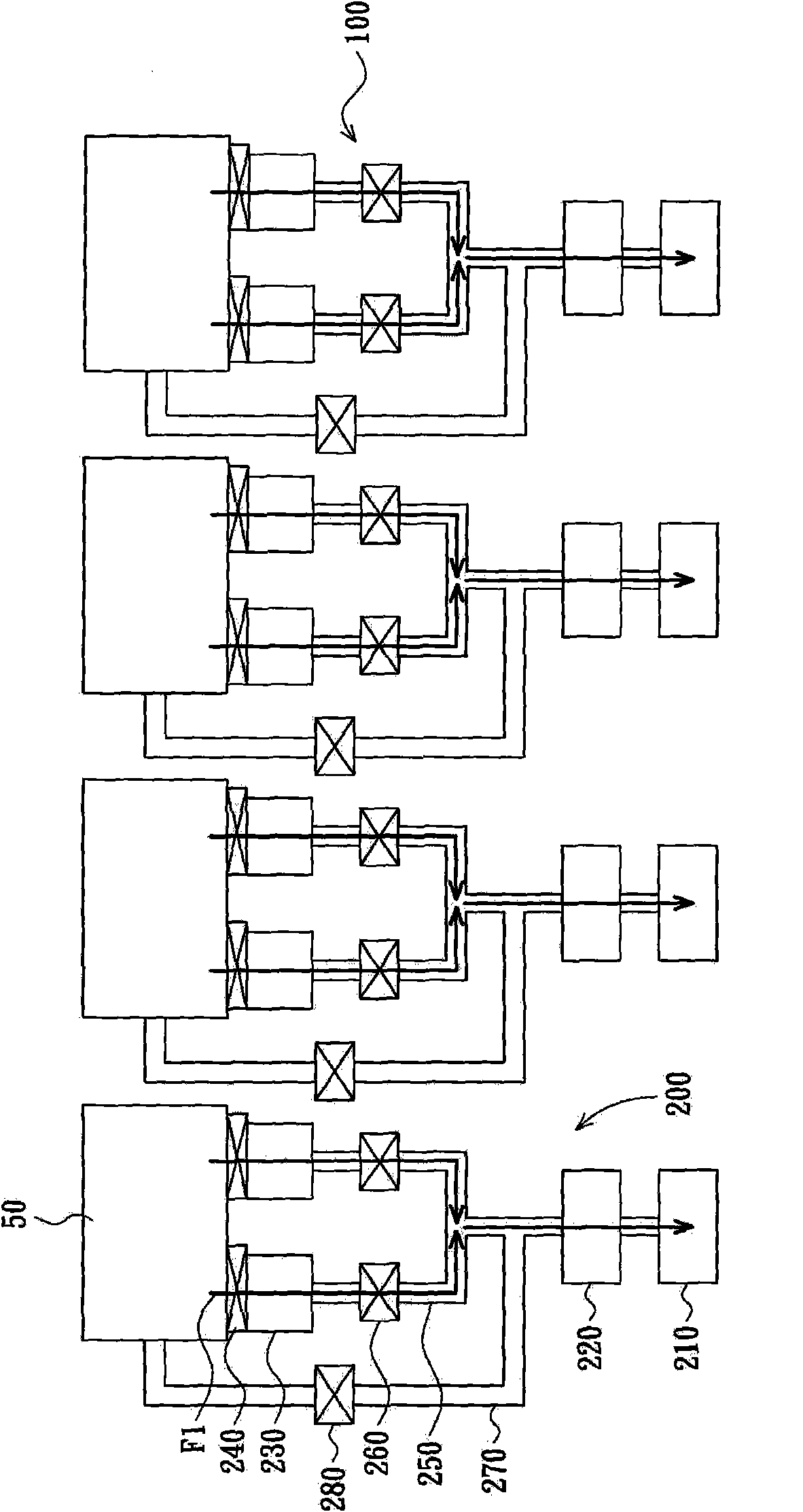

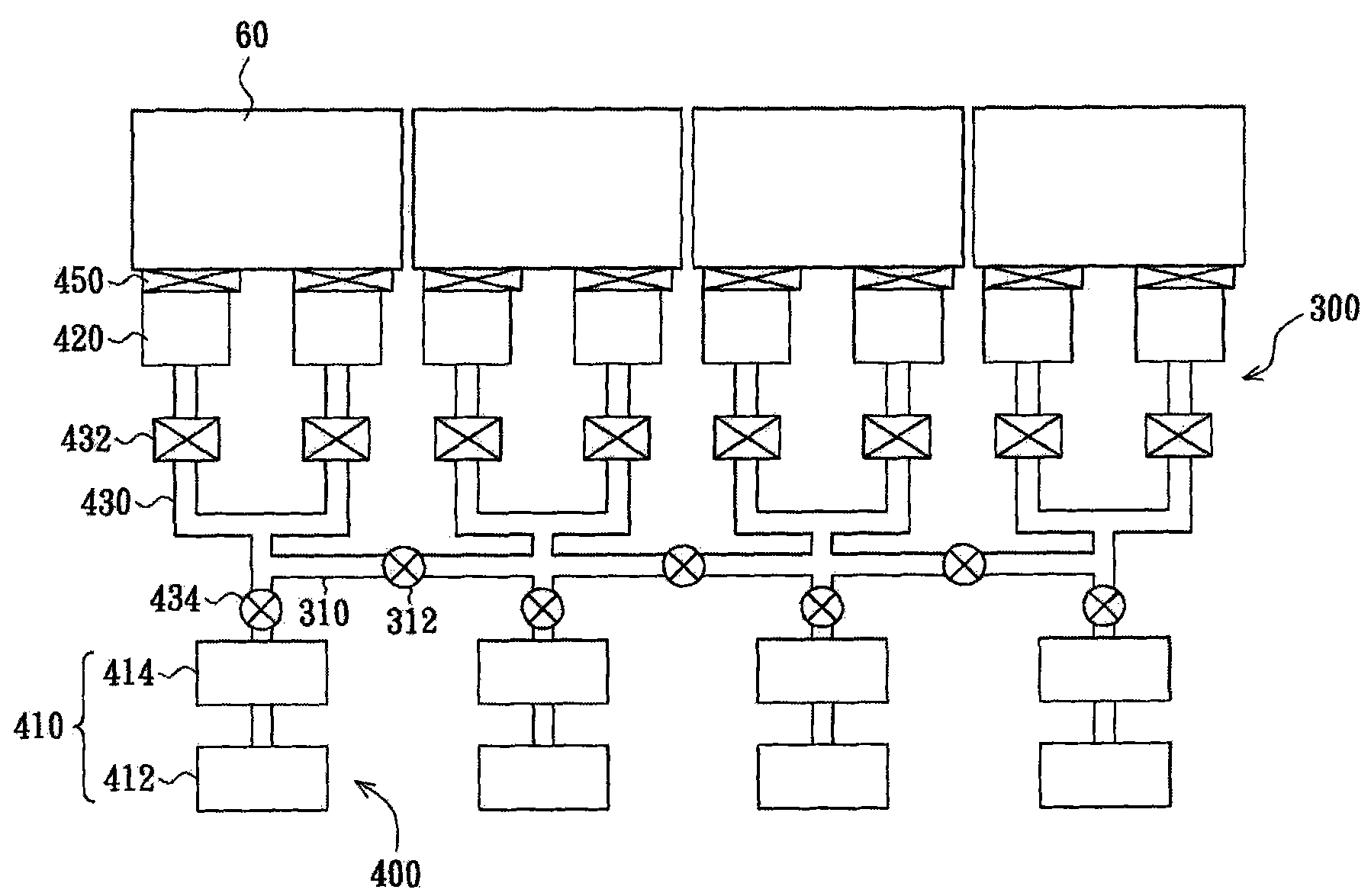

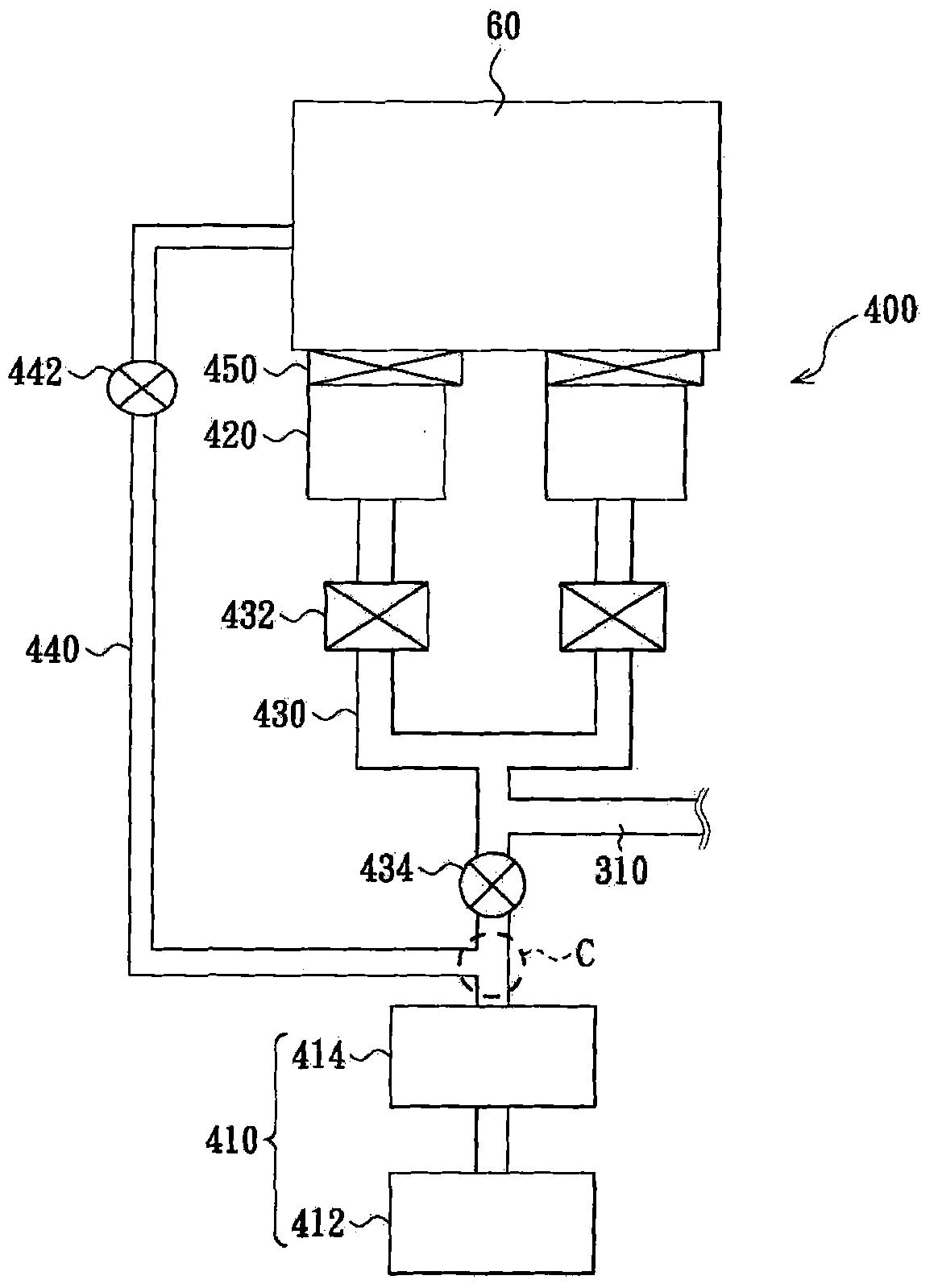

[0051] figure 2 is a schematic diagram of a vacuum device according to an embodiment of the present invention, wherein figure 2 The second line unit of each pumping unit is omitted. image 3 yes figure 2 Schematic diagram of a single pumping unit in . Please refer to figure 2 and image 3 , the vacuum device 300 of this embodiment is suitable for providing a vacuum environment in the plurality of chambers 60 . The vacuum device 300 includes a plurality of air extraction units 400 and a third pipeline unit 310 . Each pumping unit 400 is connected to one of the plurality of chambers 60, and each pumping unit 400 includes a low vacuum pumping device 410, at least one high vacuum pumping device 420 ( figure 2 Take two high vacuum pumping devices 420 as an example), the first pipeline unit 430 and the second pipeline unit 440 . The high vacuum pumping device 420 is disposed between the low vacuum pumping device 410 and the corresponding chamber 60 , and is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com