Multipurpose vertical device for testing comprehensive properties of HSK tool system

A technology of system synthesis and testing equipment, which is applied in the direction of measuring equipment, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as waste, and achieve the effects of saving manufacturing costs, compact structure, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

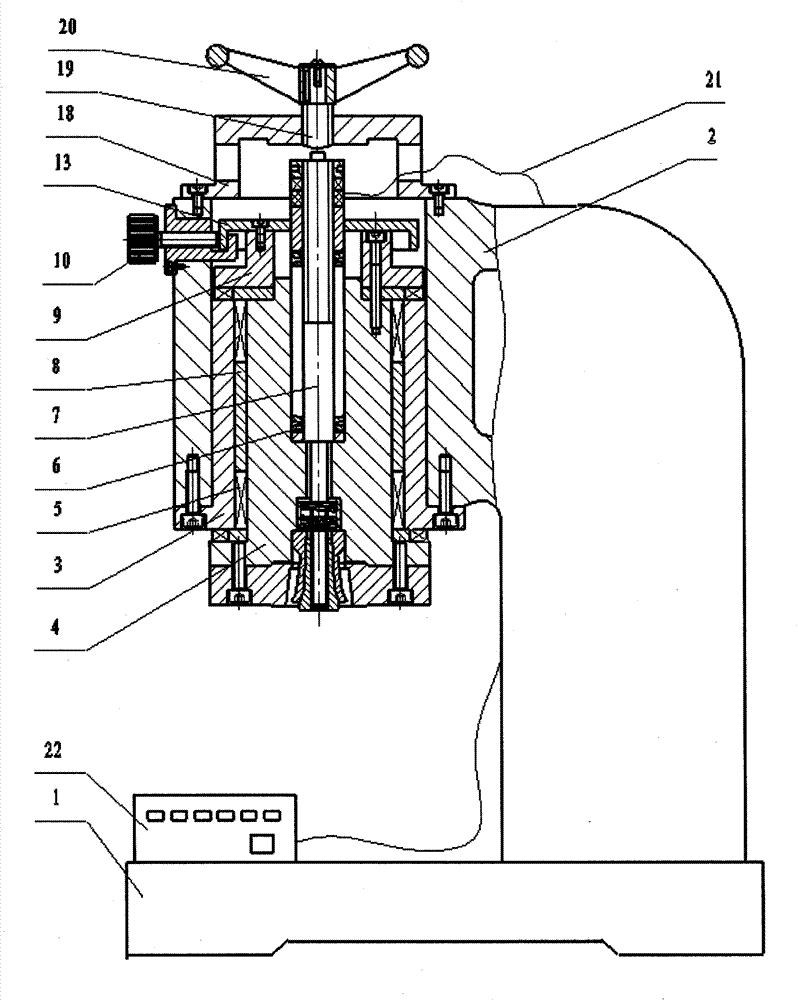

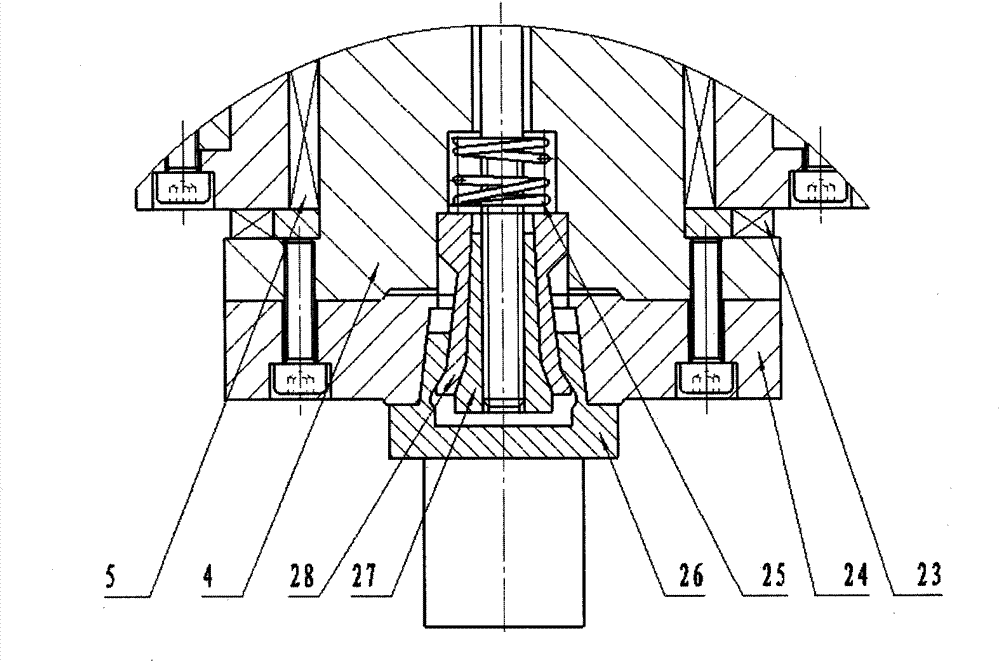

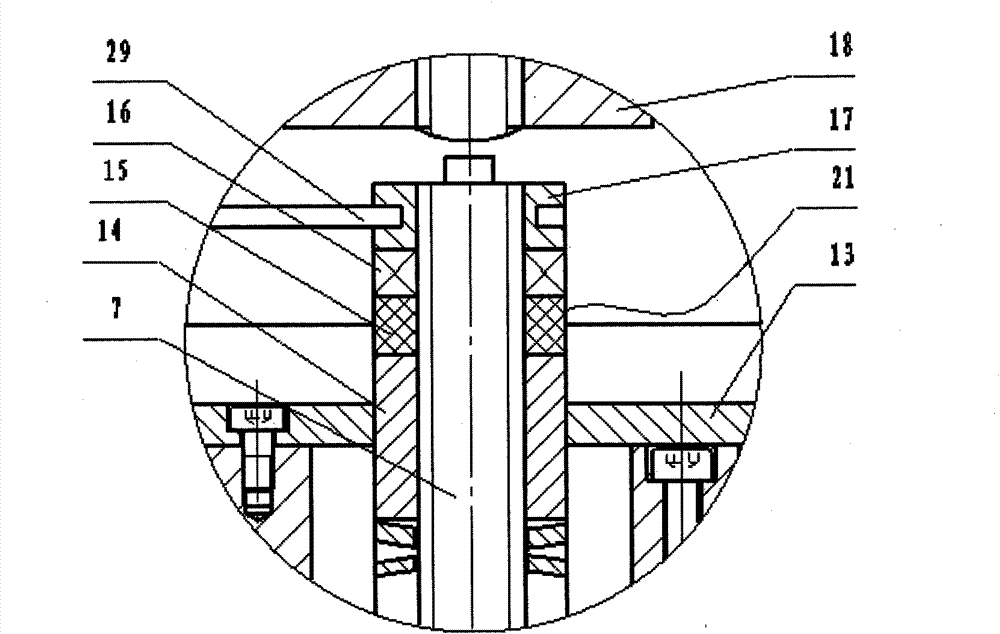

[0028] Such as figure 1, 2,3,4 shown, by the device of the present invention is by base 1, vertical box body 2, main shaft mechanism, HSK tool handle seat 24, tool handle clamping structure, knife handle loading and unloading mechanism, clamping force adjustment device , Clamping force measuring device, spindle locking device. Among them: the main part of the vertical box 2 is a hollow cylinder, the inner hole of which is precisely bored, used to install the main shaft structure, the outer side of the hollow cylinder is cast in one with a column, the hollow cylinder is parallel to the column, and the lower end of the column is fixed by bolts On the base 1, the hollow cylinder and the column in the vertical box 2 are all perpendicular to the base 1, and the contact surfaces of the base 1 and the vertical box 2 are all scraped to ensure flatness. The main shaft mechanism is installed in the vertical box body 2 through screws, and different types of HSK tool holders 24 are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com