Auxiliary device for manufacturing cable head

An auxiliary device and cable head technology, which is used in equipment for disassembling/armored cables, equipment for connecting/terminating cables, metal processing, etc., can solve the problems of poor cable head consistency, uneven trimming, laborious operation, etc. To achieve the effect of reducing labor intensity, convenient and quick assembly and disassembly, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

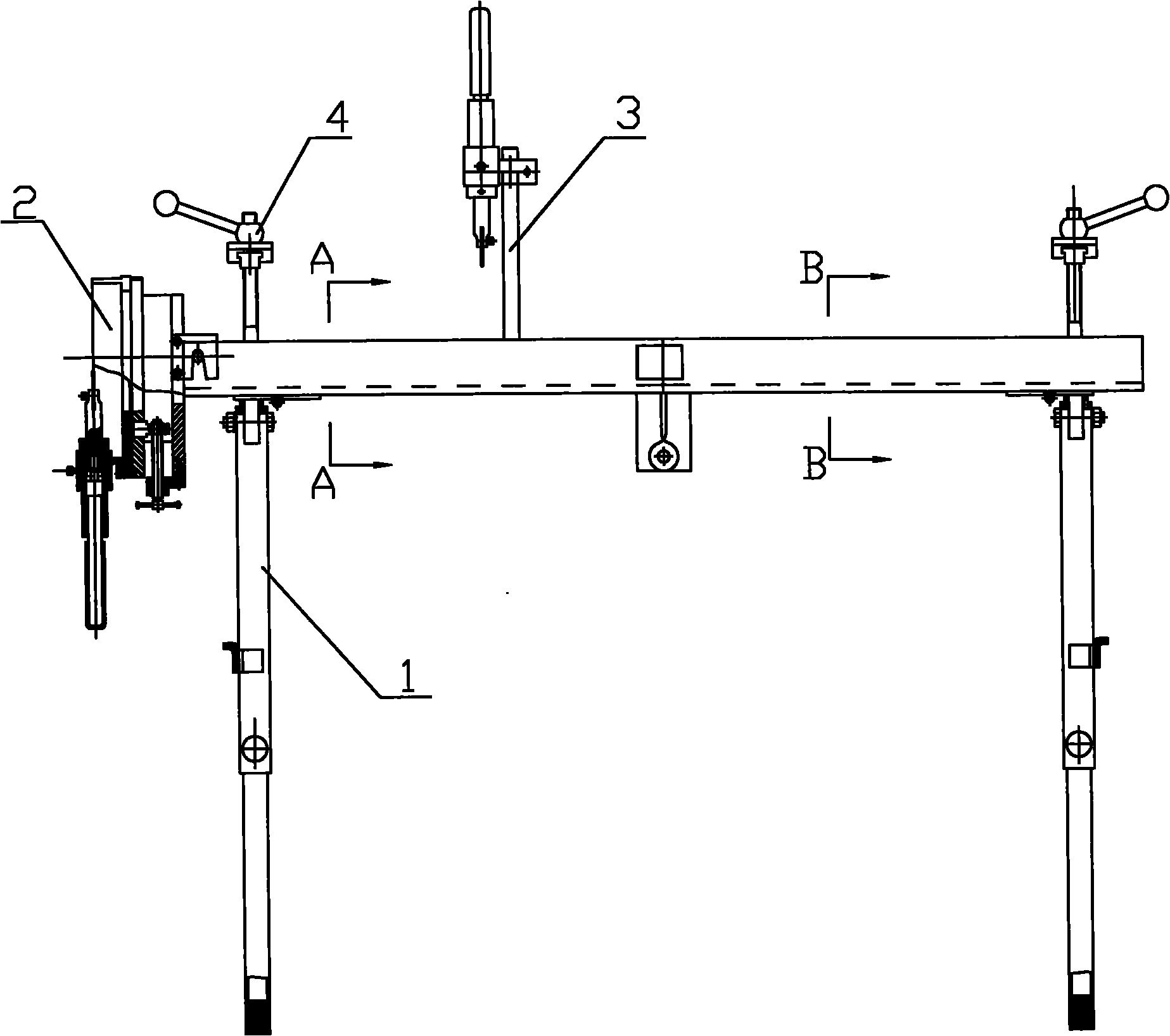

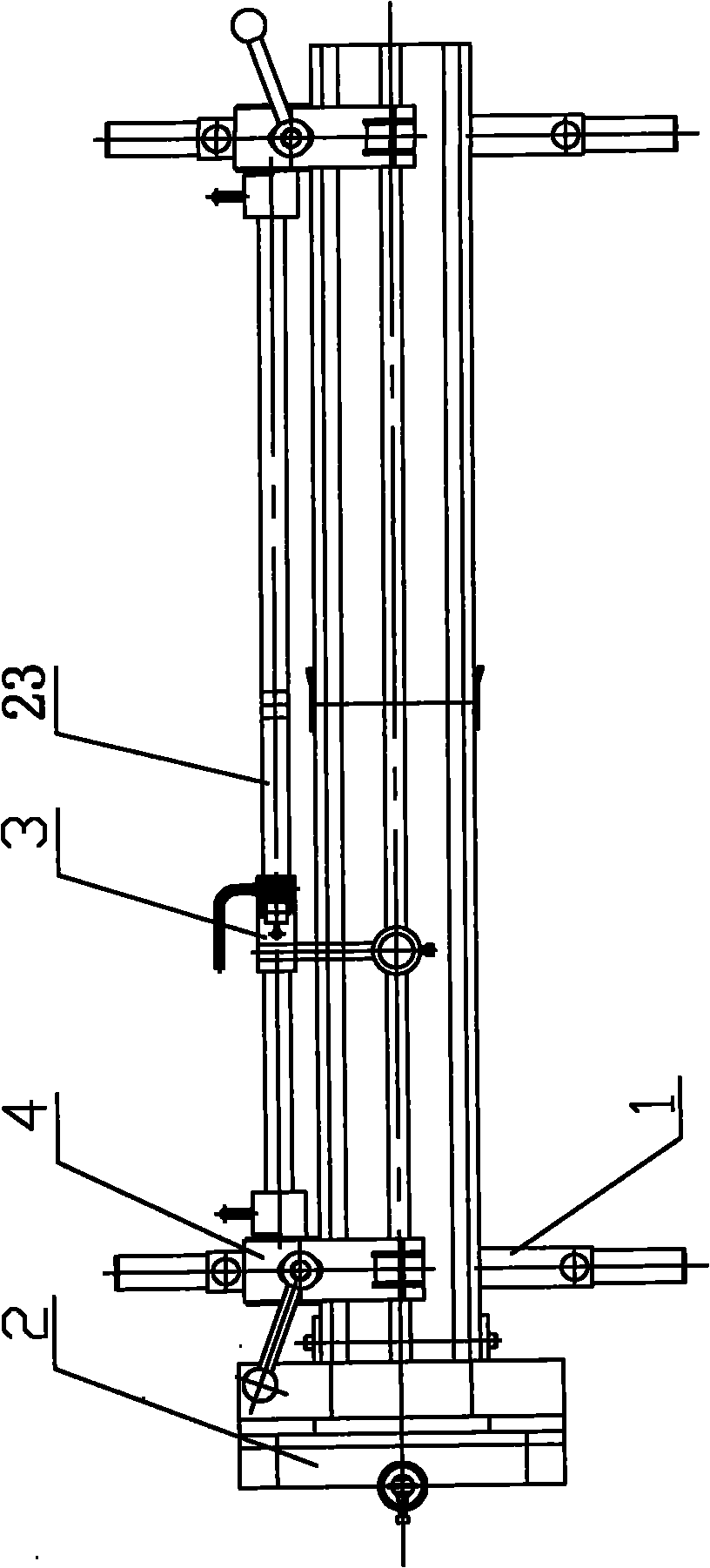

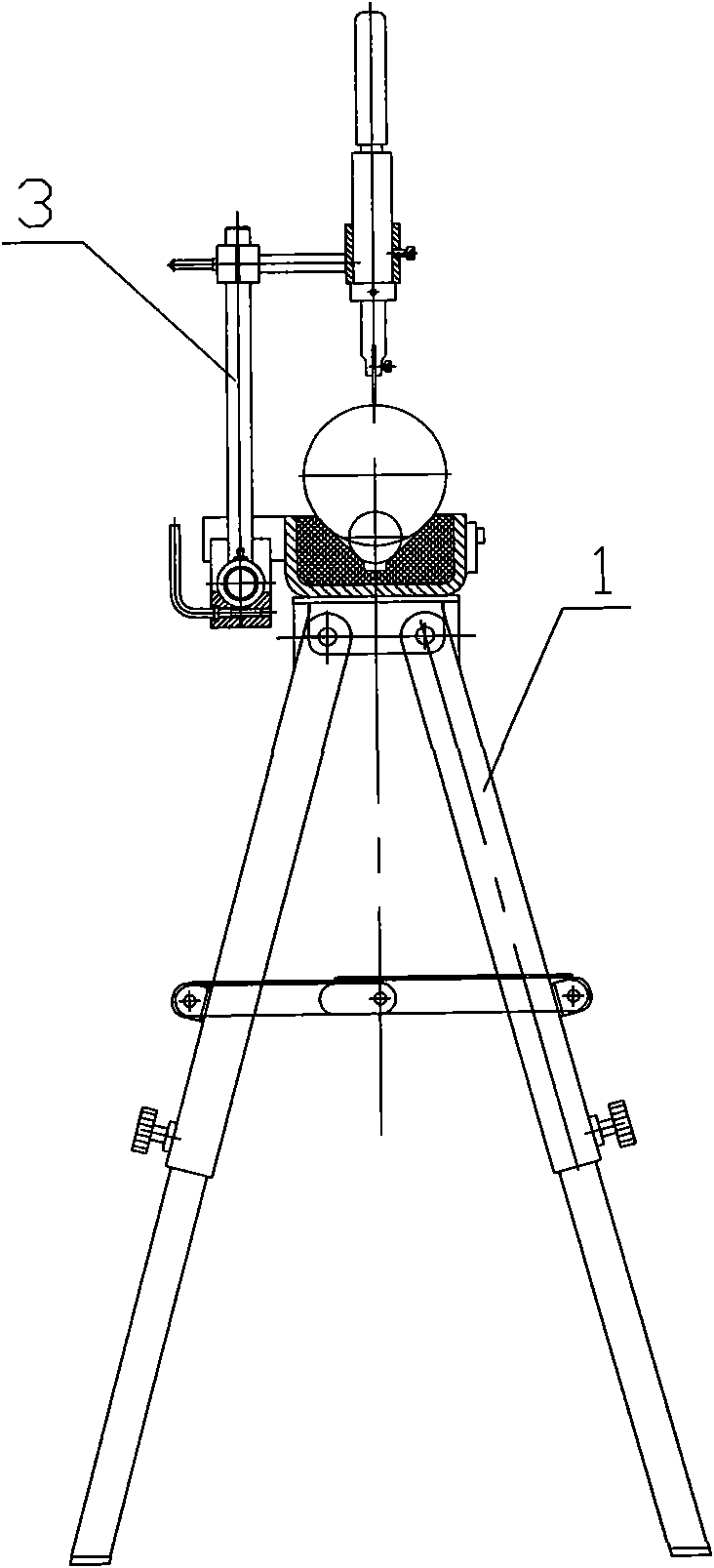

[0027] like Figure 1 to Figure 4 As shown, the auxiliary device for making cable heads according to the present invention has a frame 1 and a rotary cutting mechanism 2 , a linear cutting mechanism 3 and a pressing mechanism 4 installed on the frame 1 . The rotary cutting mechanism 2 is used to realize radial stripping and cutting of the cable sheath, the linear cutting mechanism 3 is used to realize axial stripping and cutting of the cable sheath, and the pressing mechanism 4 is used to compress and position the cable on the frame 1 superior. figure 2 , image 3 The double dotted line circle in the middle represents the outer contour of the cable line.

[0028] see Figure 5 to Figure 8 . The frame has support legs 5 and a worktable 6 hinged on the support legs 5, and the two support legs 5 at the same end of the workbench 6 can be folded together.

[0029] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com