Transparent counterfeiting bracing wire for cigarette case package and manufacturing method thereof

An anti-counterfeiting cable and production method technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve problems such as the inability to meet the needs of manufacturers and consumers, and achieve strong anti-counterfeiting effects and simple identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

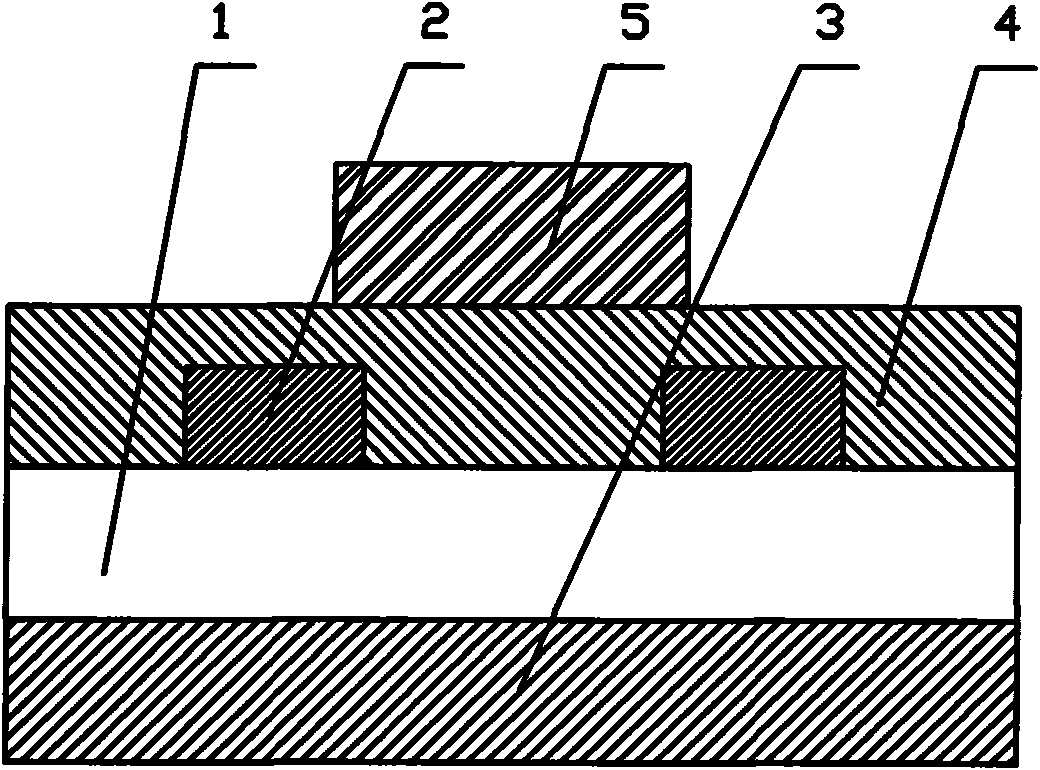

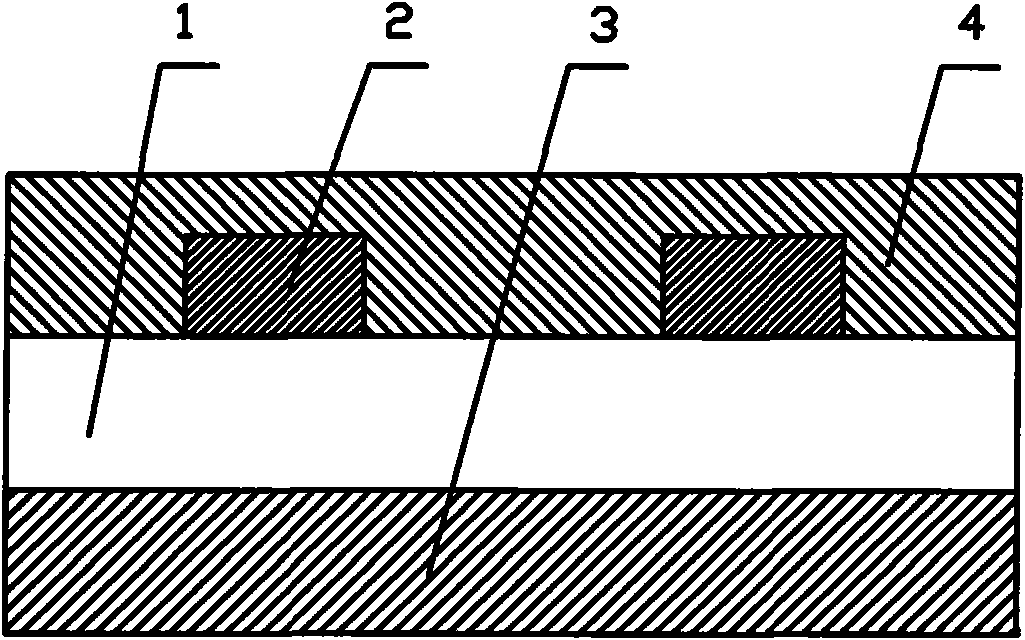

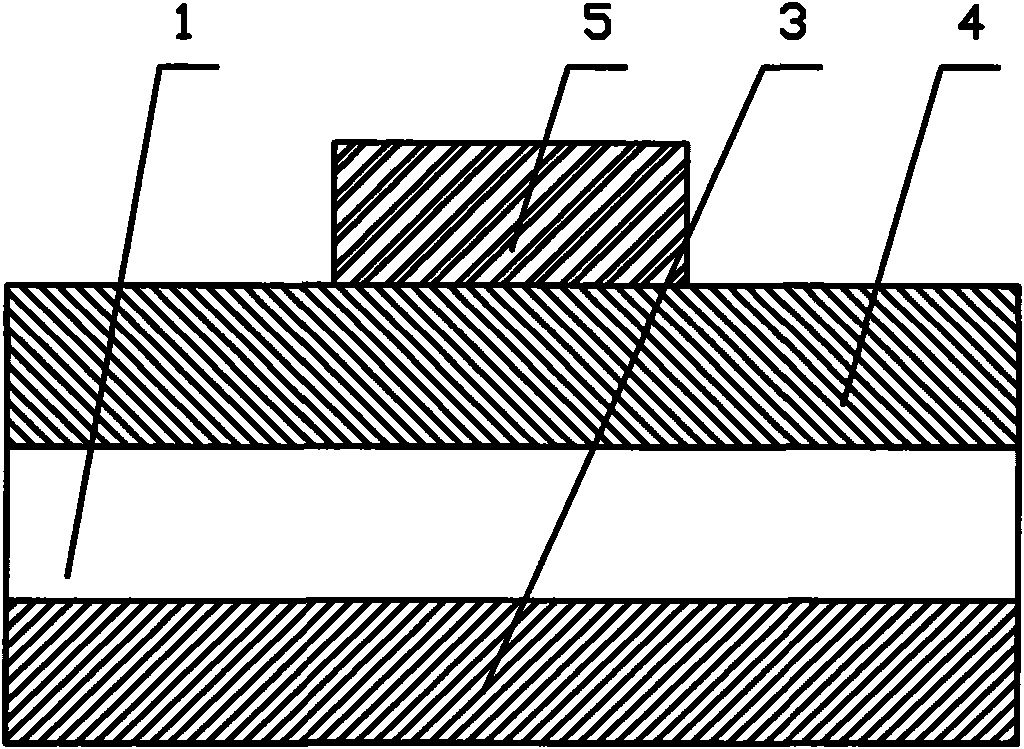

[0019] The specific implementation manners and related technical problems of the present invention will be further described in detail below in conjunction with the accompanying drawings. The biggest difference between the backguy of the present invention and the backguy of the prior art lies in its anti-counterfeiting function. In the prior art, ordinary ink is also used to print characters or patterns on the base layer 1 of the backguy. This kind of backguy also has a certain anti-counterfeiting function. The pattern is more difficult and must be seen under a magnifying glass. Moreover, this production method is relatively simple, and it is easy for counterfeiters to imitate. as attached figure 1 Shown is a schematic view of the structure of an embodiment of the present invention, in this embodiment, the base layer 1 is arranged on the release layer 3, and the text or / and pattern layer printed with anti-counterfeiting ink is partially arranged on the base layer 1; The ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com