Novel belt anti-deviation control system for belt conveyer

A belt conveyor and control system technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as abnormal work, accidents, and uneven force on the belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

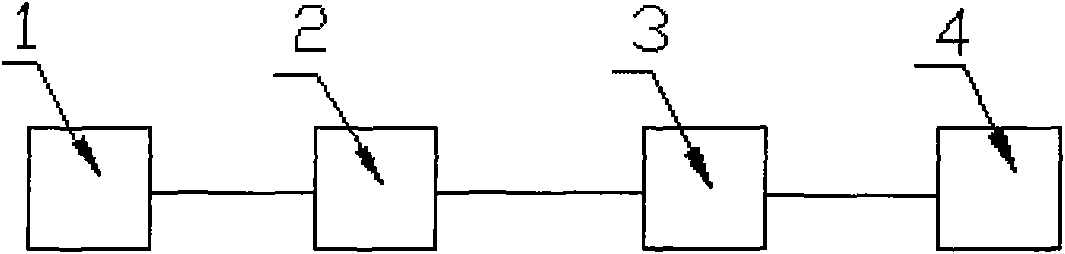

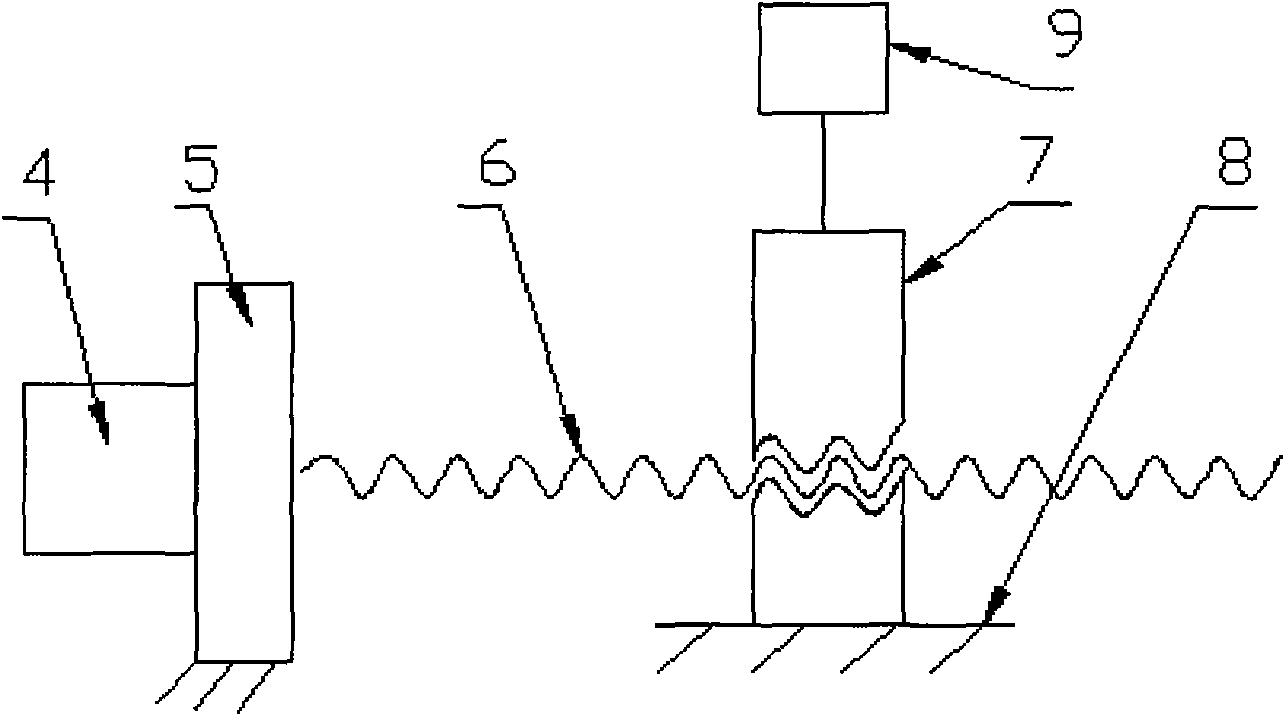

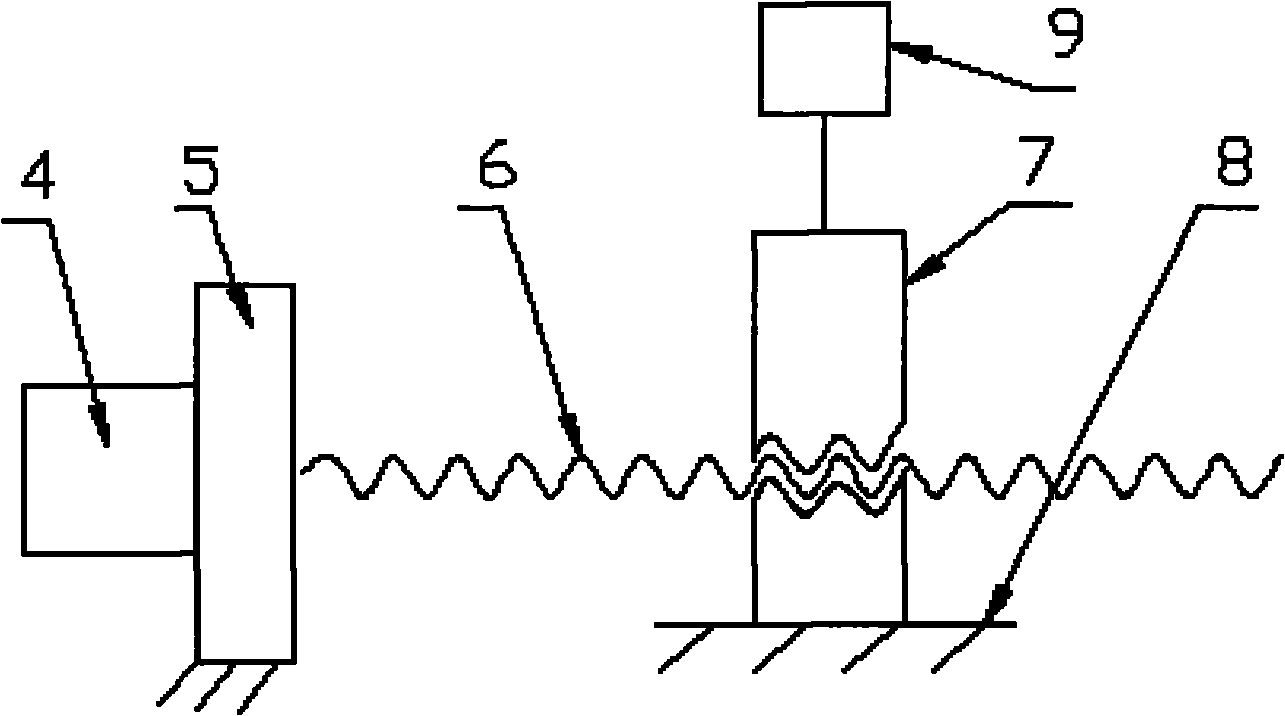

[0010] Install the infrared emitting device (1) and the infrared receiving device (2) at appropriate positions on the upper and lower sides of the belt respectively, the infrared emitting device (1) and the infrared receiving device (2) form a signal source, and the output interface of the infrared receiving device (1) It is connected with the signal input port of the programmable controller (3), the signal output port of the programmable controller (3) is connected with the servo motor (4), the output shaft of the servo motor (4) is connected with the input of the reducer (5) The shafts are connected, the output shaft of the reducer (5) is fixedly connected with one end of the screw (6), the slider (7) is connected with the screw (6) through its own thread, and at the same time, the slider is installed at the set In the guide rail (8), the slide block (7) has a degree of freedom of movement in the guide rail (8), and the direction of its motion is consistent with the axis of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com