Slag soil transfer system

A muck and back door technology, applied in transportation and packaging, loading/unloading, garbage collection, etc., can solve the problems of difficulty in loading muck and excessive throwing, and achieve the effect of reducing lifting work, saving fuel consumption, and fast loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

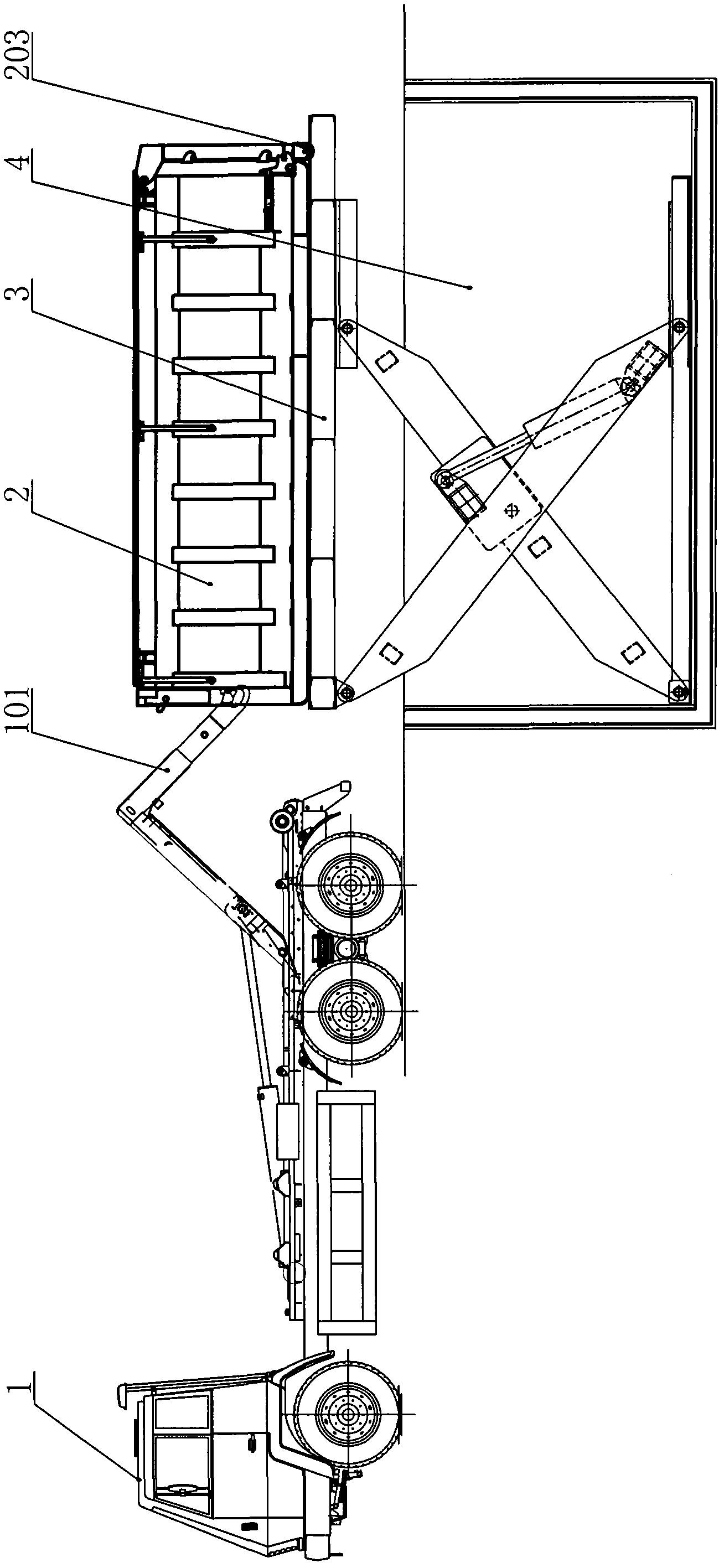

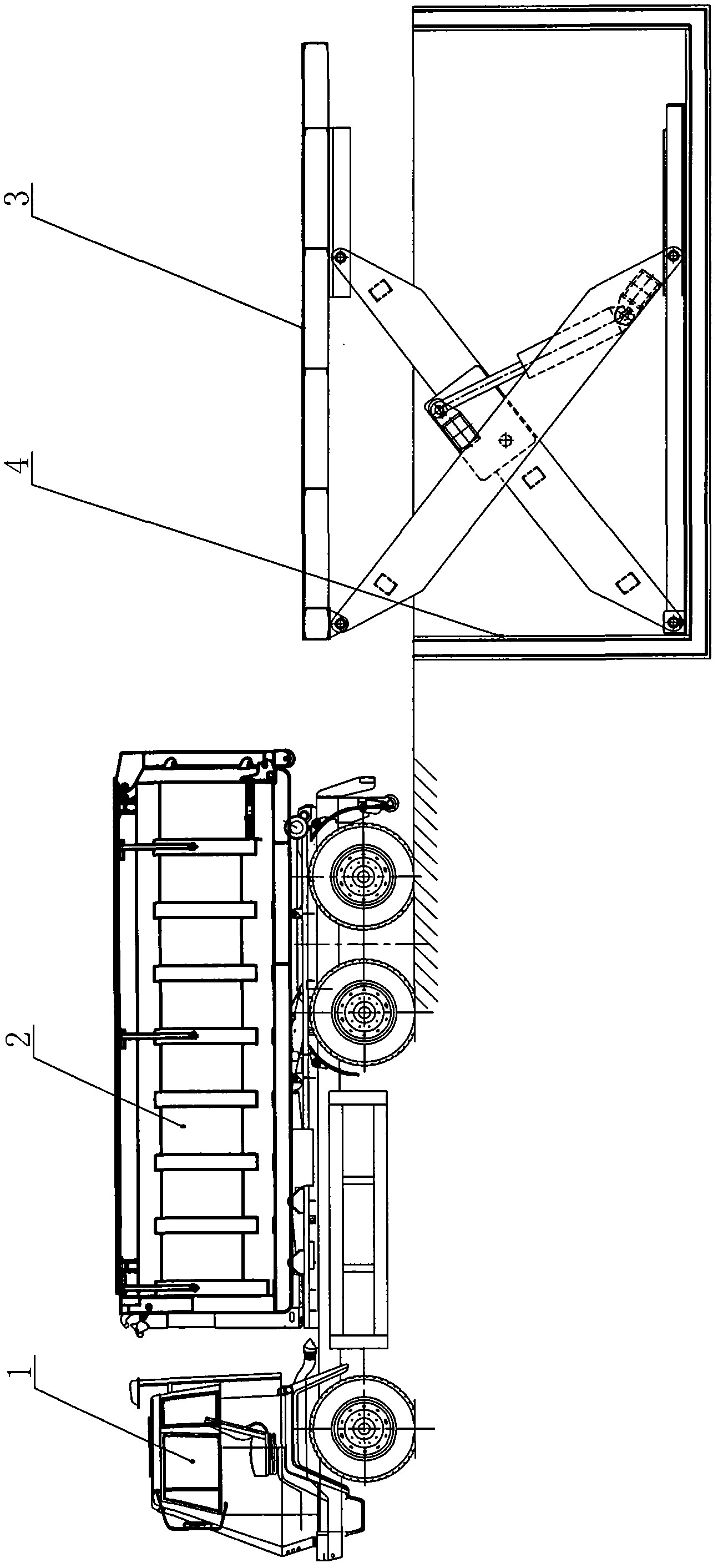

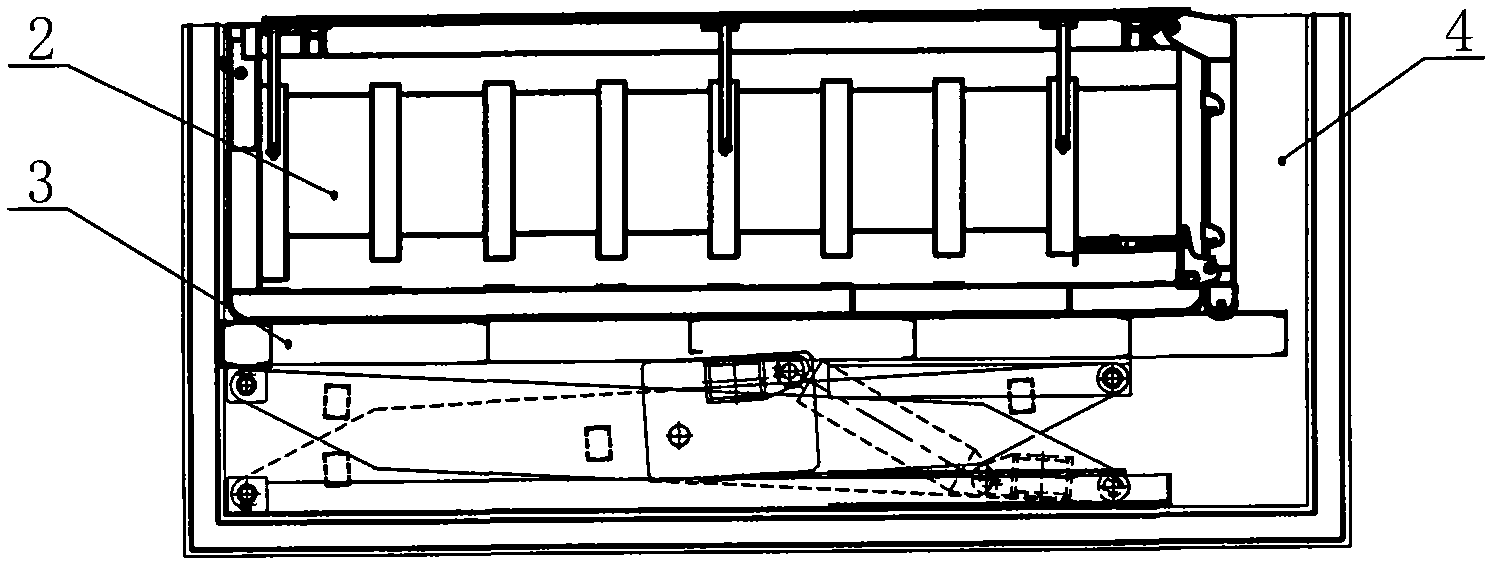

[0033] Such as figure 1 As shown, the muck transfer system of the present invention includes a muck box 2, a pit 4, a lifting platform 3 and a pull-arm vehicle 1, and the pull-arm vehicle 1 is provided with a traction mechanism for pushing the muck box 2 out or pulling it on the floor of its compartment. Arm 101, the free end of traction arm 101 is provided with tow hook; The upper plane of 2 is flat with the ground, and when the loading platform 301 rises to the loading position, the loading platform 301 is flat with the compartment floor of the pulling arm vehicle 1 . figure 1 Shown is the working state of transferring the muck box 2 from the lifting platform 3 to the pulling arm vehicle 1 after loading is completed. The lifting platform 3 is raised to be level with the floor of the compartment of the muck truck, and the towing hook of the traction arm 101 of the pull-arm truck is snapped into the traction ring on the front wall panel of the muck box 2, and the front part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com