Method for manufacturing medicinal ventilated adhesive tape base material

A manufacturing method and technology of tape, which are applied in bandages, medical science, textiles and papermaking, etc., can solve the problems of troublesome operation, time-consuming and labor-intensive, and many times of contact between hands and tape, and achieve the effect of reducing drying time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

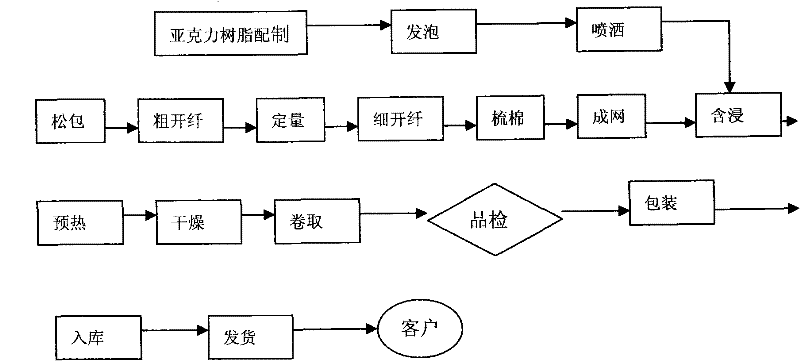

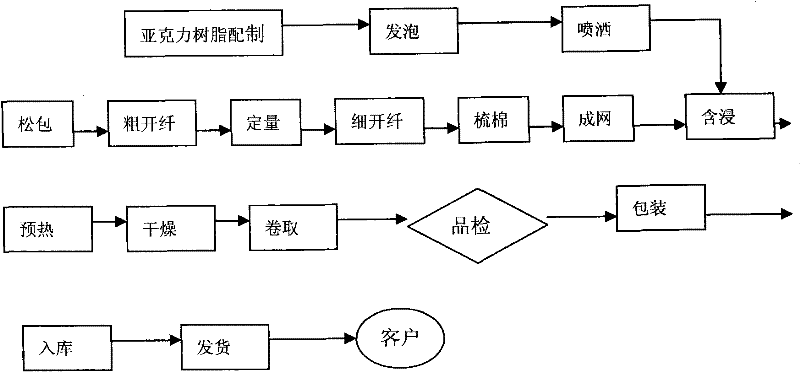

[0014] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] The invention adopts cotton-like viscose fiber that can be naturally decomposed as the base material, and adopts low-width Malin environmental protection resin as an adhesive for fiber bonding, which has the characteristics of environmental protection.

[0016] The manufacture method of medical air-permeable adhesive tape base material among the present invention comprises the following steps:

[0017] (1) loosely pack the fiber: unpack the whole package of fiber, and put it into the feeding cotton box in a dispersed manner;

[0018] (2) Coarse opening of loose-packed fibers: use a set of nail-shaped needle rows to loosen the fibers;

[0019] (3) Quantitative: Weigh a certain weight of fiber: set the required fiber weight on the control panel of the automatic scale to control the weight of the fiber entering;

[0020] (4) finely ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com